U-shaped sealing member

A seal, U-shaped technology, applied in engine seals, piston pump seals, pump components, etc., can solve problems such as insufficient seal stability, difficulty in application, and adverse effects on seal performance, and achieve durability and seal stability Excellent performance, low cost and manufacturing, and excellent sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the present invention will be described in detail based on the illustrated embodiments.

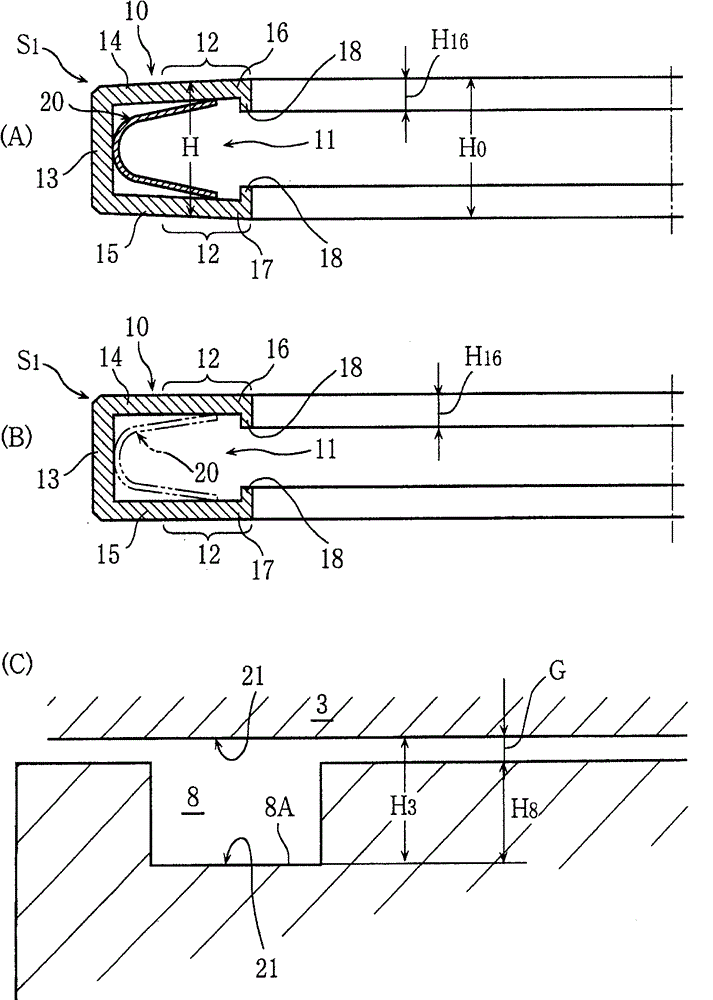

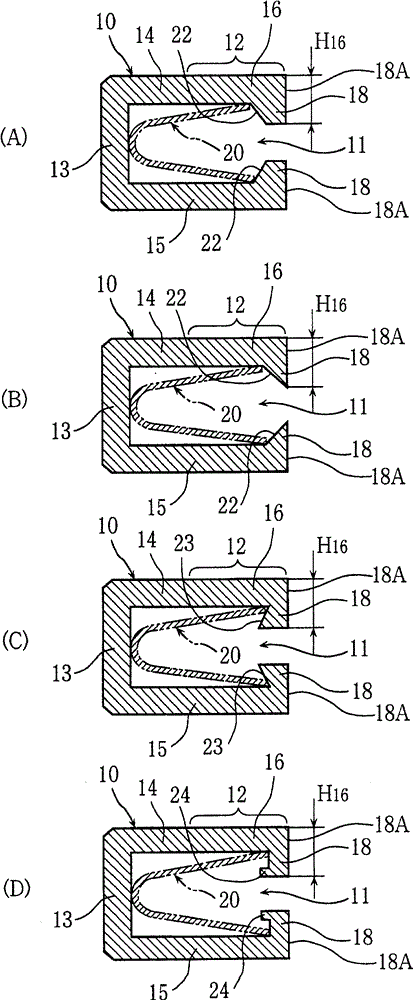

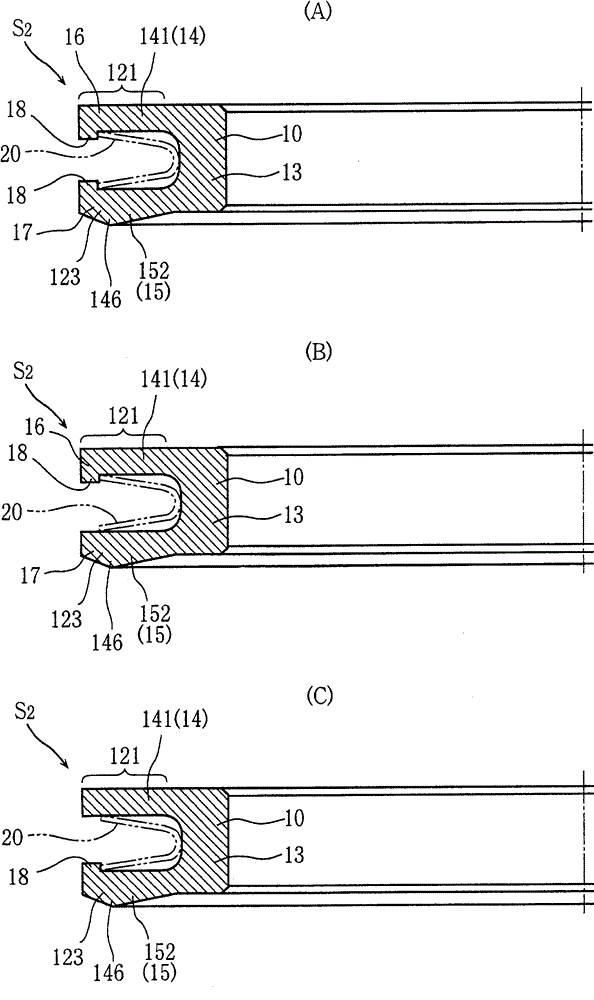

[0034] figure 1 In, the U-shaped seal S to which the present invention is applied is exemplified 1 , S 2 The sealing structure of the scroll compressor 2 seals the planar minute gap G between the scroll 3 performing the eccentric rotation M of the scroll compressor 2 and the fixed housing 4 .

[0035] figure 2 will be figure 1 The detailed diagram of the Y part is enlarged, as shown in the figure 1 as well as figure 2 As shown, with an axis L 4 Large diameter and small diameter U-shaped seals S are arranged concentrically at the center 1 , S 2 .

[0036] U-shaped seal S of the first embodiment 1 It opens radially inward and has a large diameter. The U-shaped seal S of the second embodiment 2 The opening radially outward is a small diameter. Sealed fluids are, for example, cooling media and oil. If along an axis L 4 look in the direction of figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com