Patents

Literature

30results about How to "Cheap and easy to manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spline hub for clutch and manufacturing method thereof

InactiveCN104032207ACheap and easy to manufactureFull strengthFriction clutchesFurnace typesGraphiteClutch

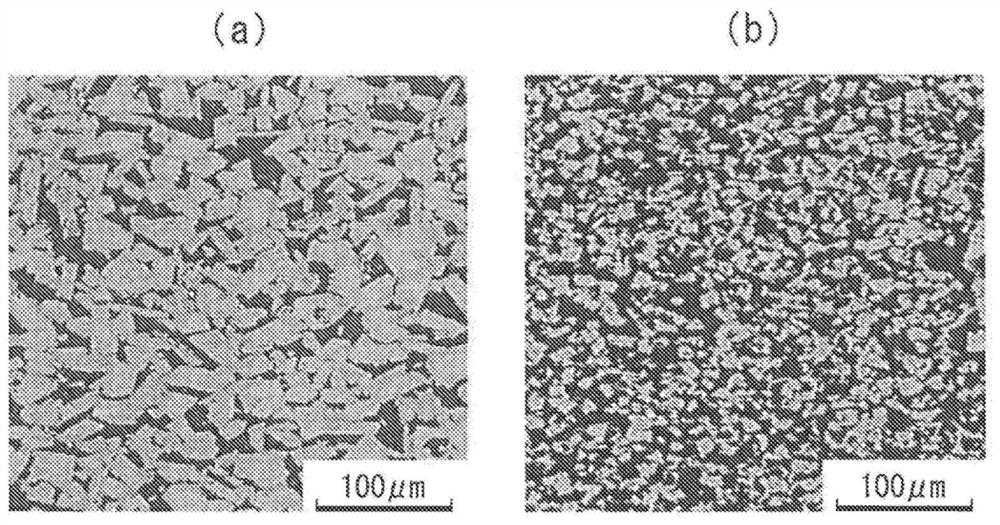

A spline hub for a clutch and a manufacturing method thereof are provided. The spline hub includes C : 3.4 ˆ¼ 3.9%, Si : 2.1 ˆ¼ 2.5%, Mn : 0.2 ˆ¼ 0.7%, P : 0.01 % or less, S : 0.009 ˆ¼ 0.02%, Cu : 0.2 ˆ¼ 0.4%, and Mg: 0.04 ˆ¼ 0.07% by weight ratio, and iron (Fe) and any inevitable impurity comprising the remainder, and has a structure in which spheroidal graphite is precipitated in an austenite matrix structure.

Owner:LG ELECTRONICS INC

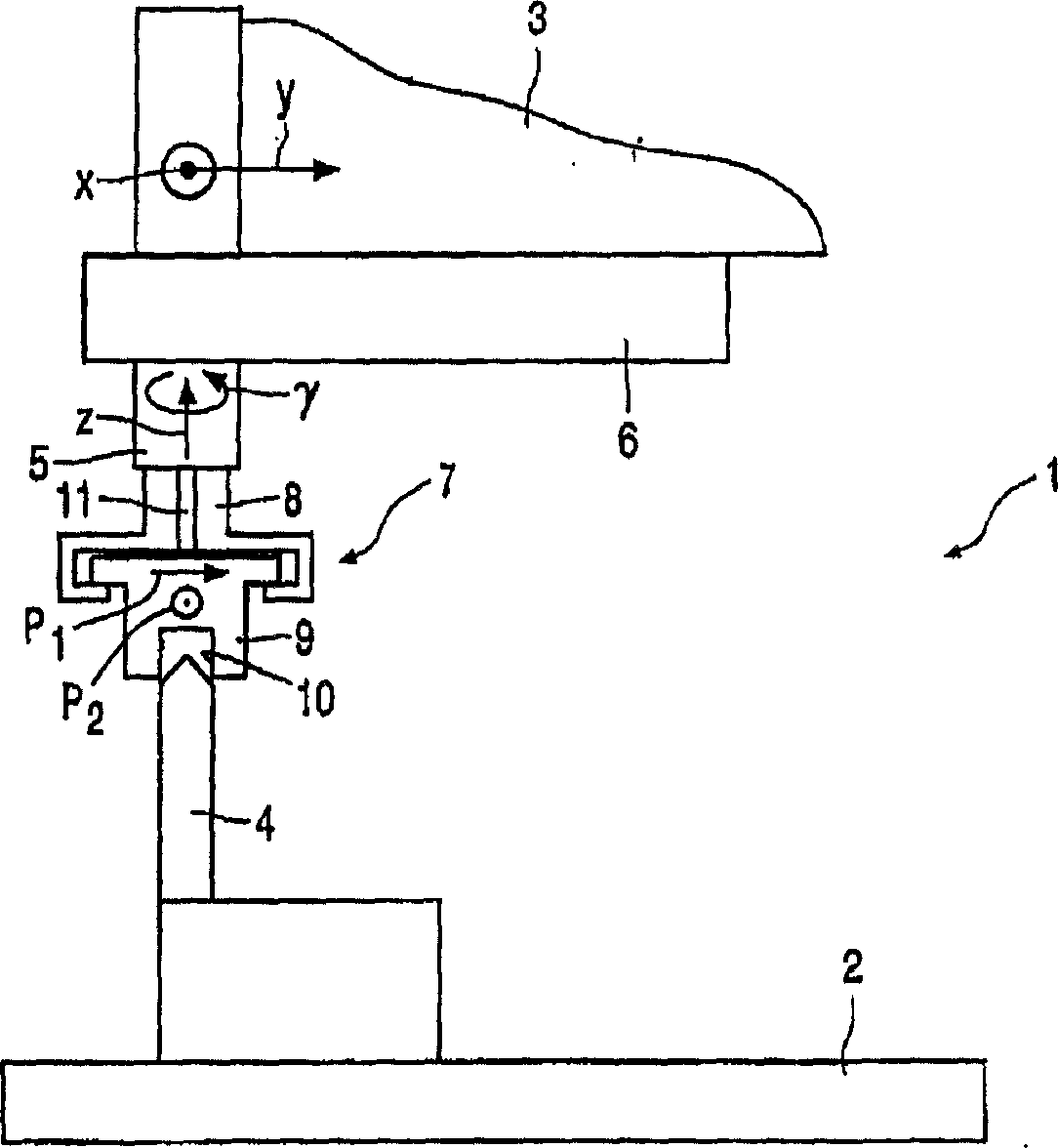

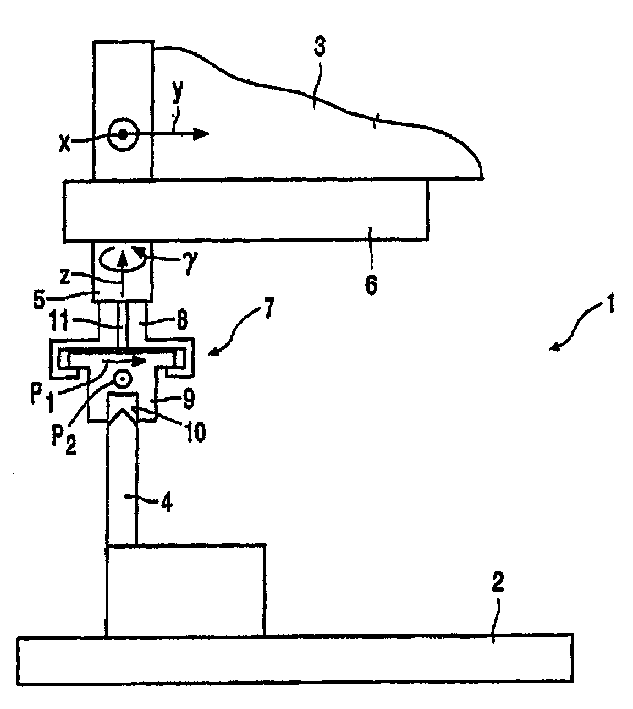

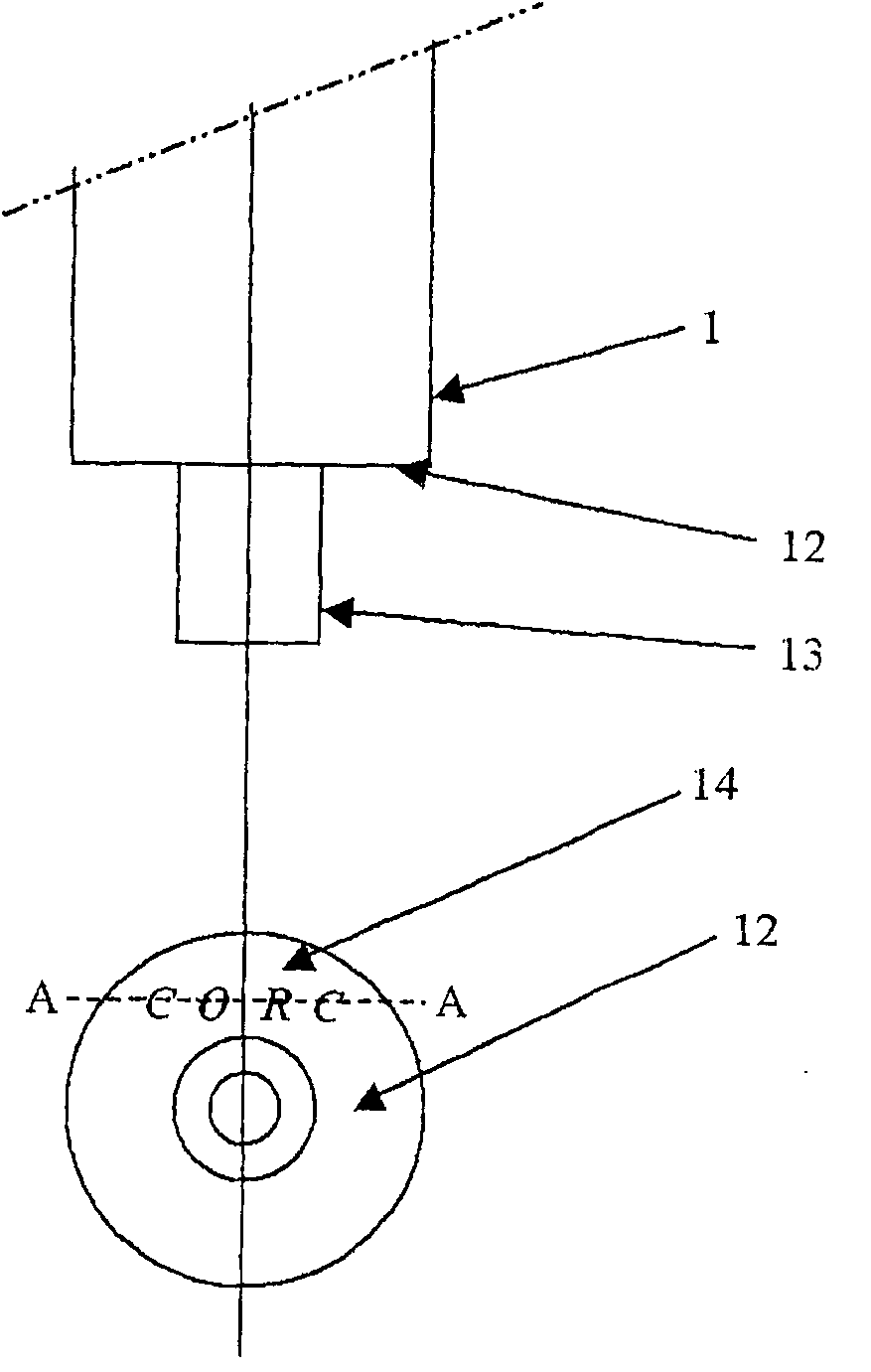

Method of calibrating a component placement machine, device suitable for carrying out such a method, and calibration component suitable for use in such a method or device

InactiveCN1582217ACheap and easy to manufactureProgramme controlProgramme-controlled manipulatorEngineeringComponent placement

Method and device for calibrating a component placement machine (1) which comprises a substrate holder (2) having at least one reference element (4) and a robot (3) having a gripper (5). A calibration component (7) is moved to an expected position of the reference element (4) relative to the robot (3) by means of the gripper (5). The calibration component (7) comprises a first part which (8) can be coupled to the gripper (5) in a removable way, and a second part (9) which is movable relative to said first part (8). The calibration component (7) is aligned relative to the reference element (4) by means of said second part (9), during which alignment said second part (9) moves relative to said first part (8). The actual relative position of the reference element (4) relative to the robot (3) is then determined on the basis of said movement.

Owner:ASSEMBLEON NV

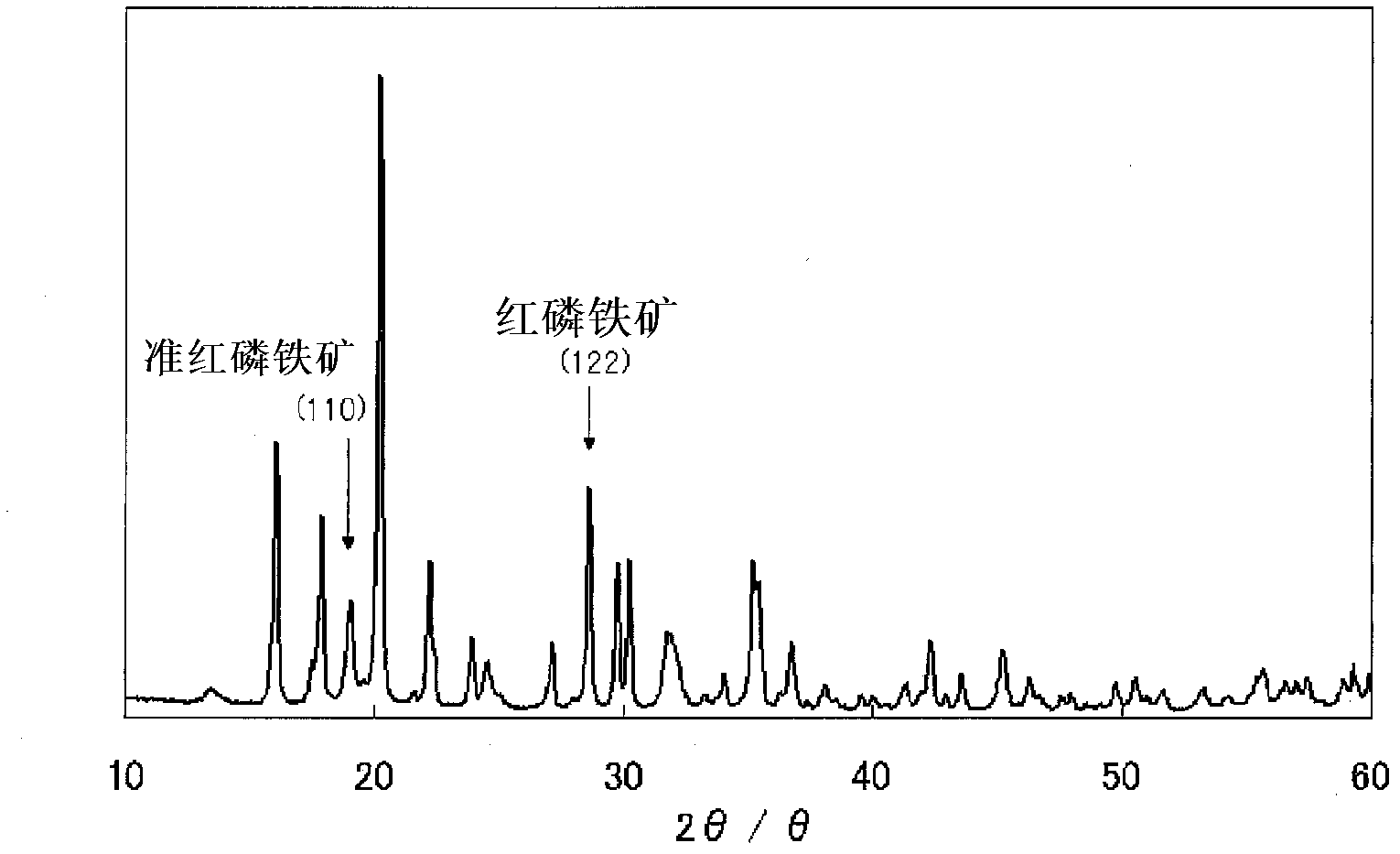

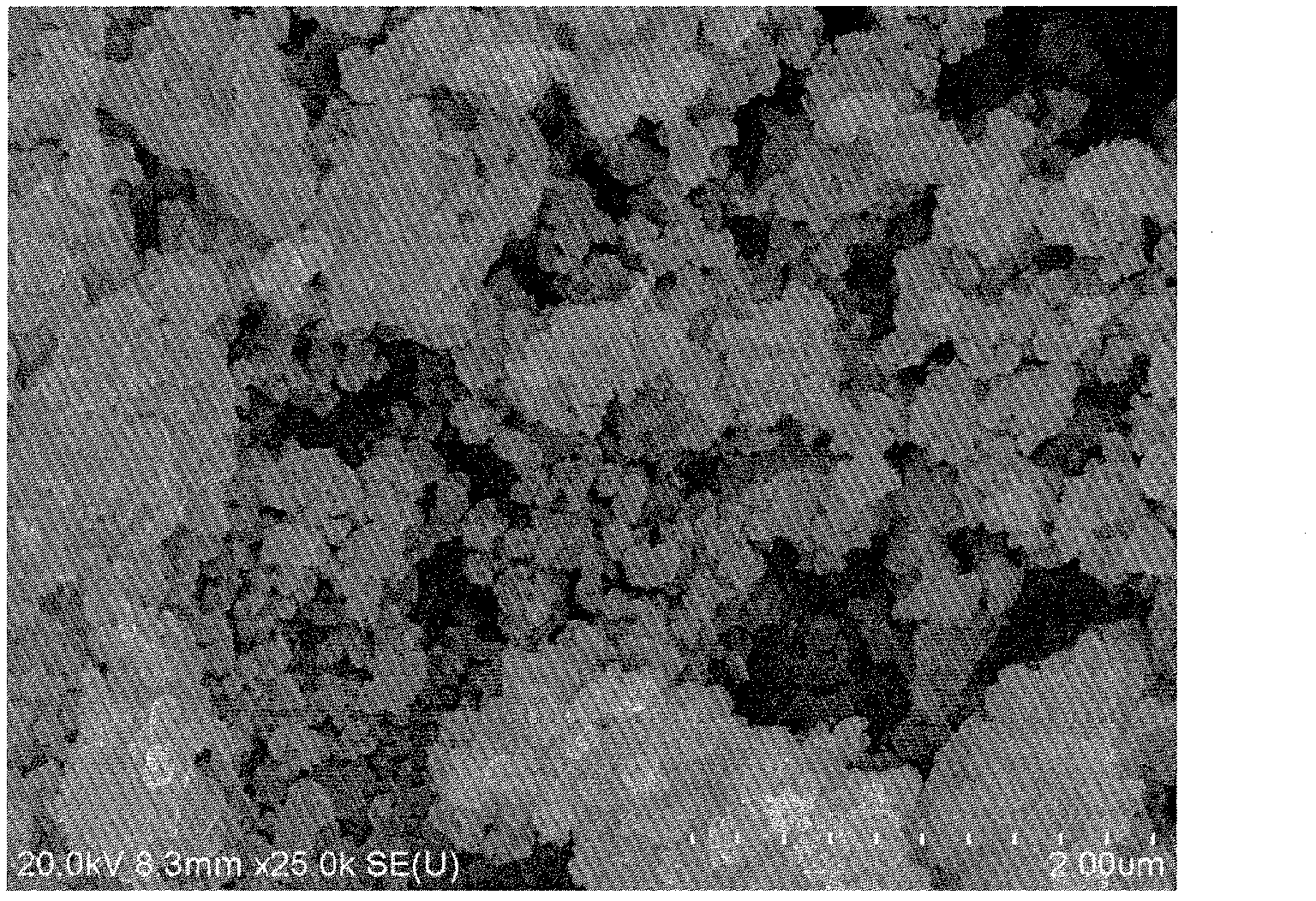

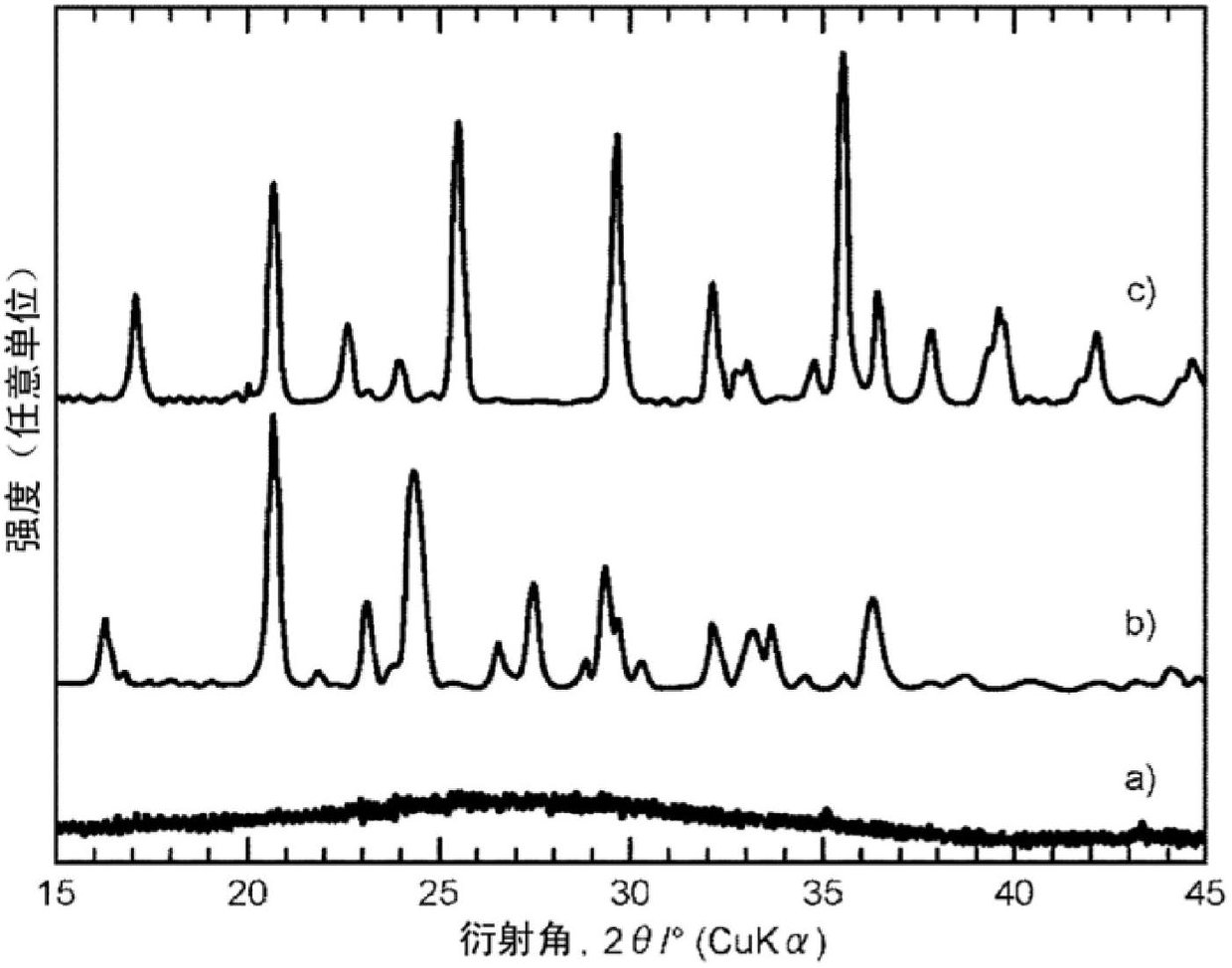

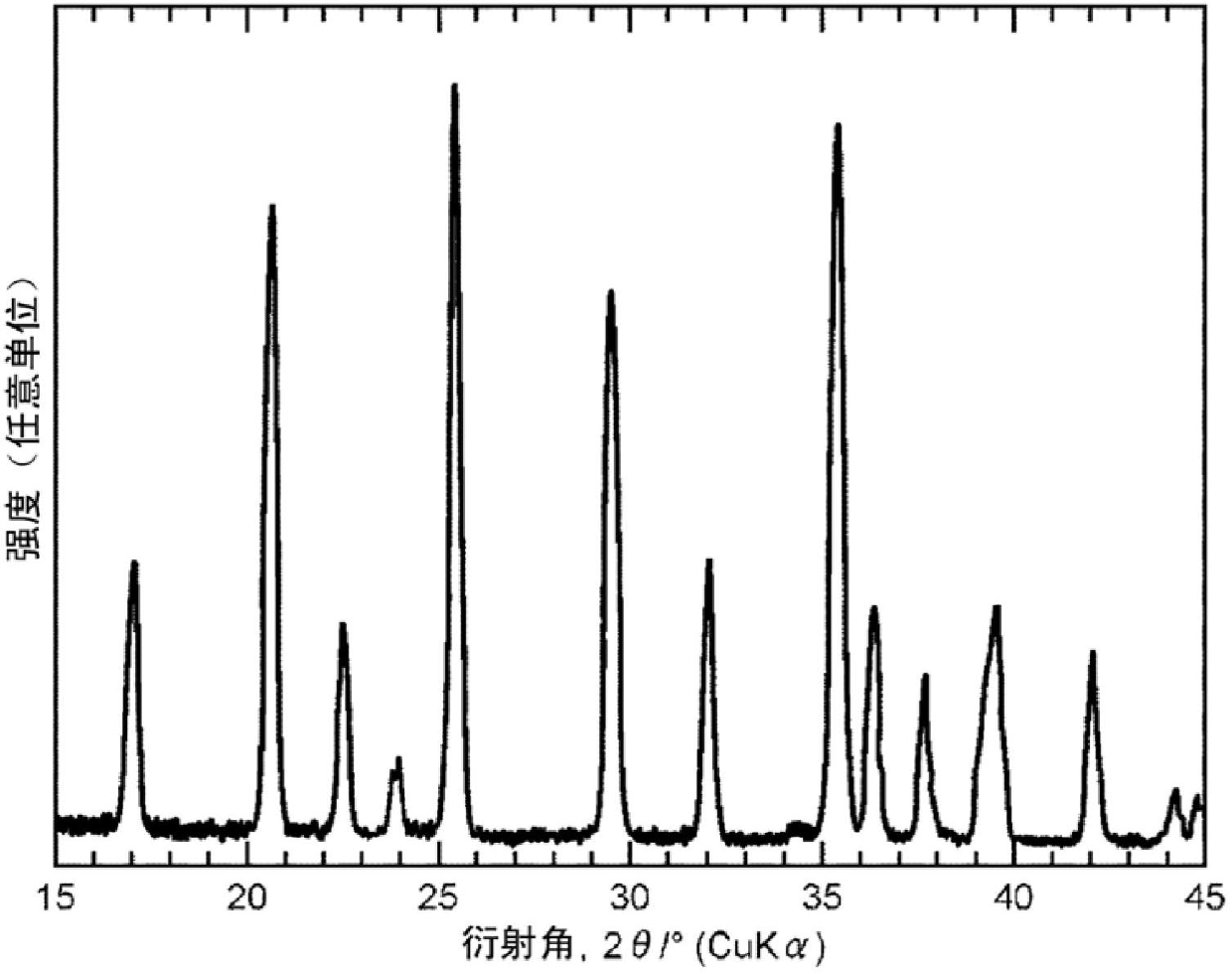

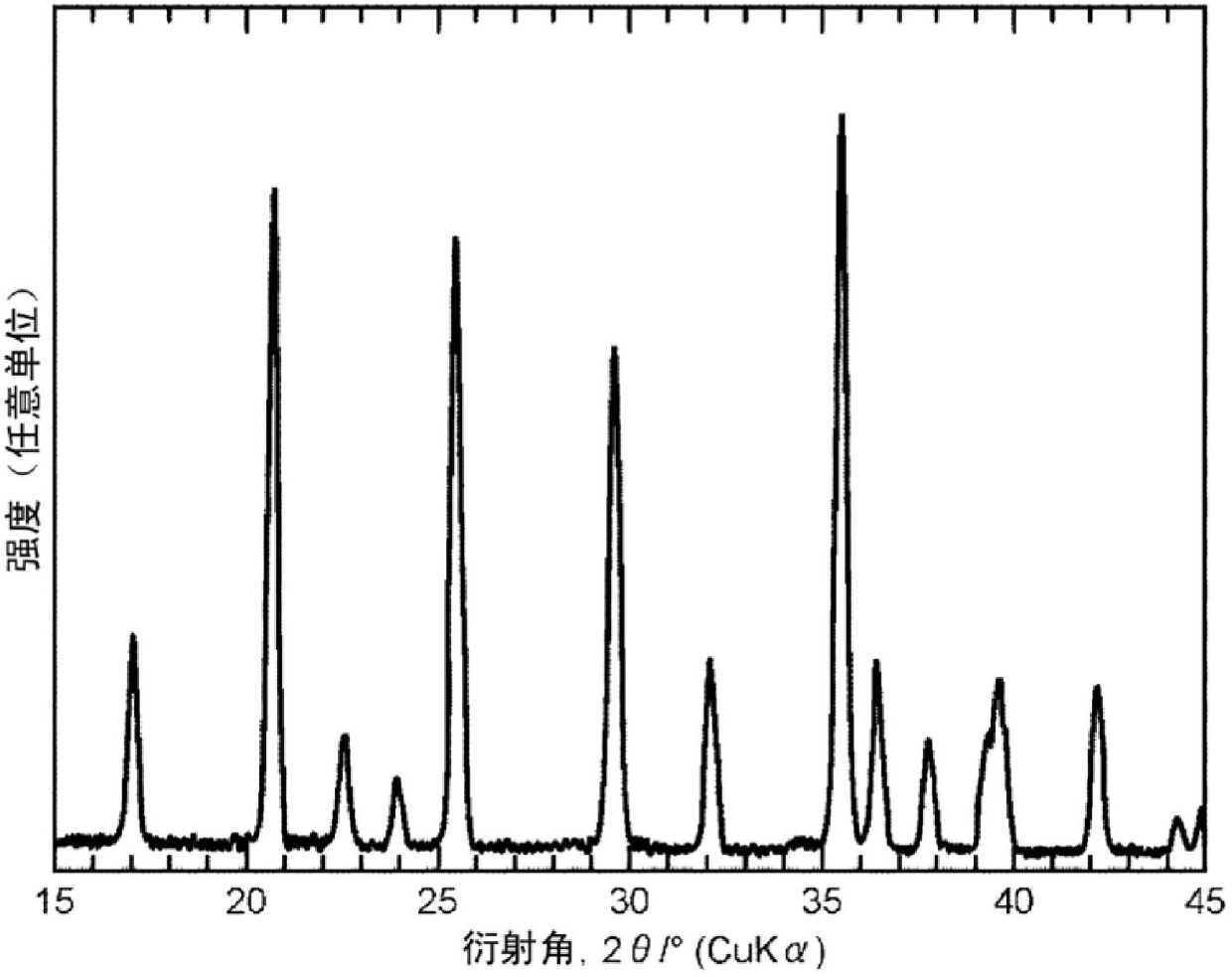

Ferric phosphate hydrate particle powder and process for production thereof, olivine-type lithium iron phosphate particle powder and process for production thereof, and non-aqueous electrolyte secondary battery

InactiveCN102612487ACheap manufacturingCheap and easy to manufactureFinal product manufactureCell electrodesPhosphoric acidFerric phosphate hydrate

Owner:TODA IND

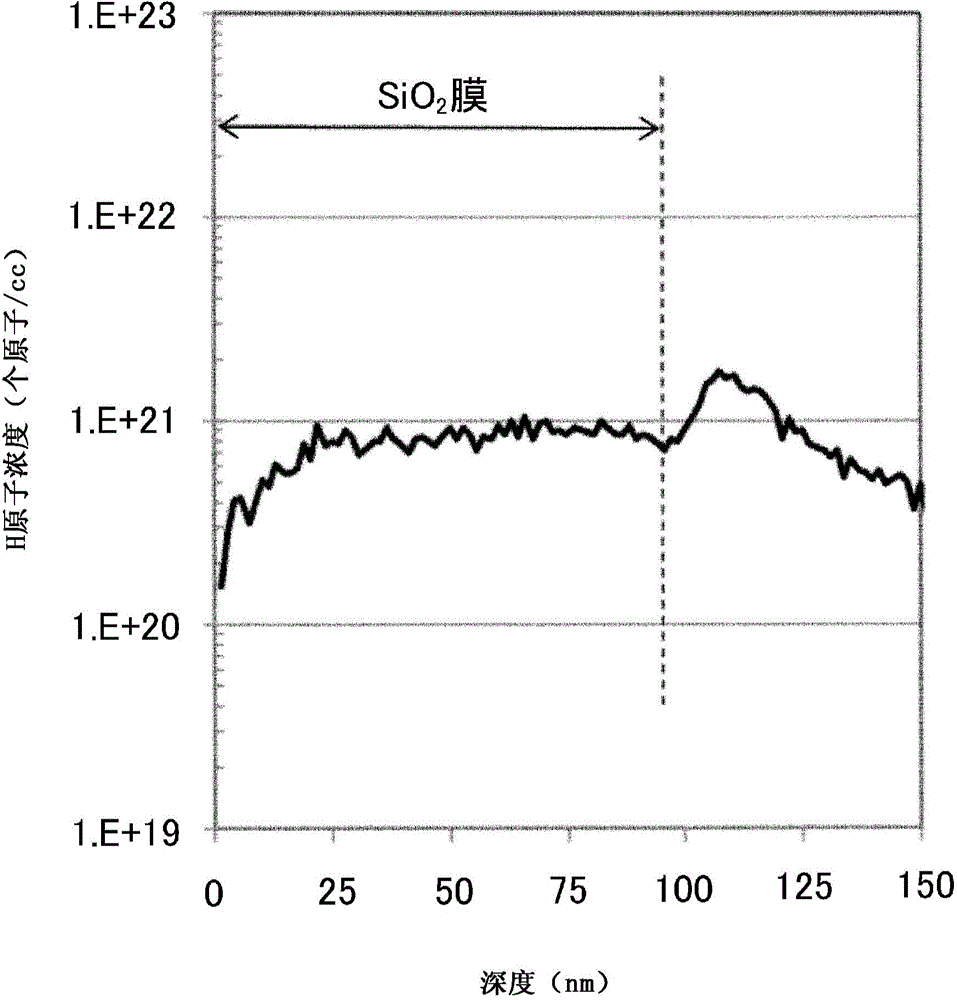

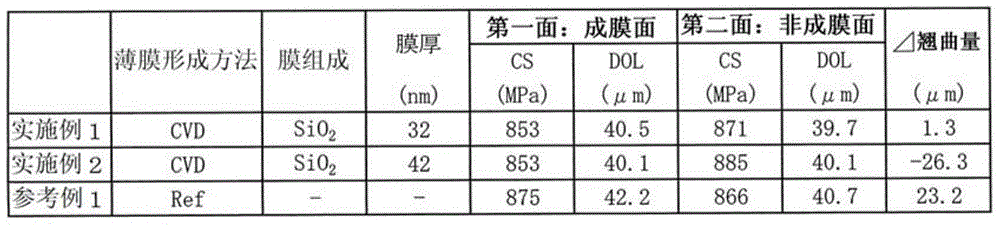

Method for reducing warping of glass substrate caused by chemically toughening treatment, and method for producing chemically toughened glass substrate

InactiveCN104010983AReduce warpageImprove productivityChemical vapor deposition coatingInorganic materialsToughened glass

A method includes: forming at least one layer of a film formed of an inorganic material, that contains H atoms in a concentration of 1.0×1015 to 1.0×1019 atom / mm3, on at least a top surface of a glass substrate having a bottom surface to contact a molten metal during forming and the top surface facing the bottom surface, thereby reducing a warpage of the glass substrate caused by a chemical strengthening process performed after forming the at least one layer on the top surface of the glass substrate. The glass substrate is formed by a float process.

Owner:AGC INC

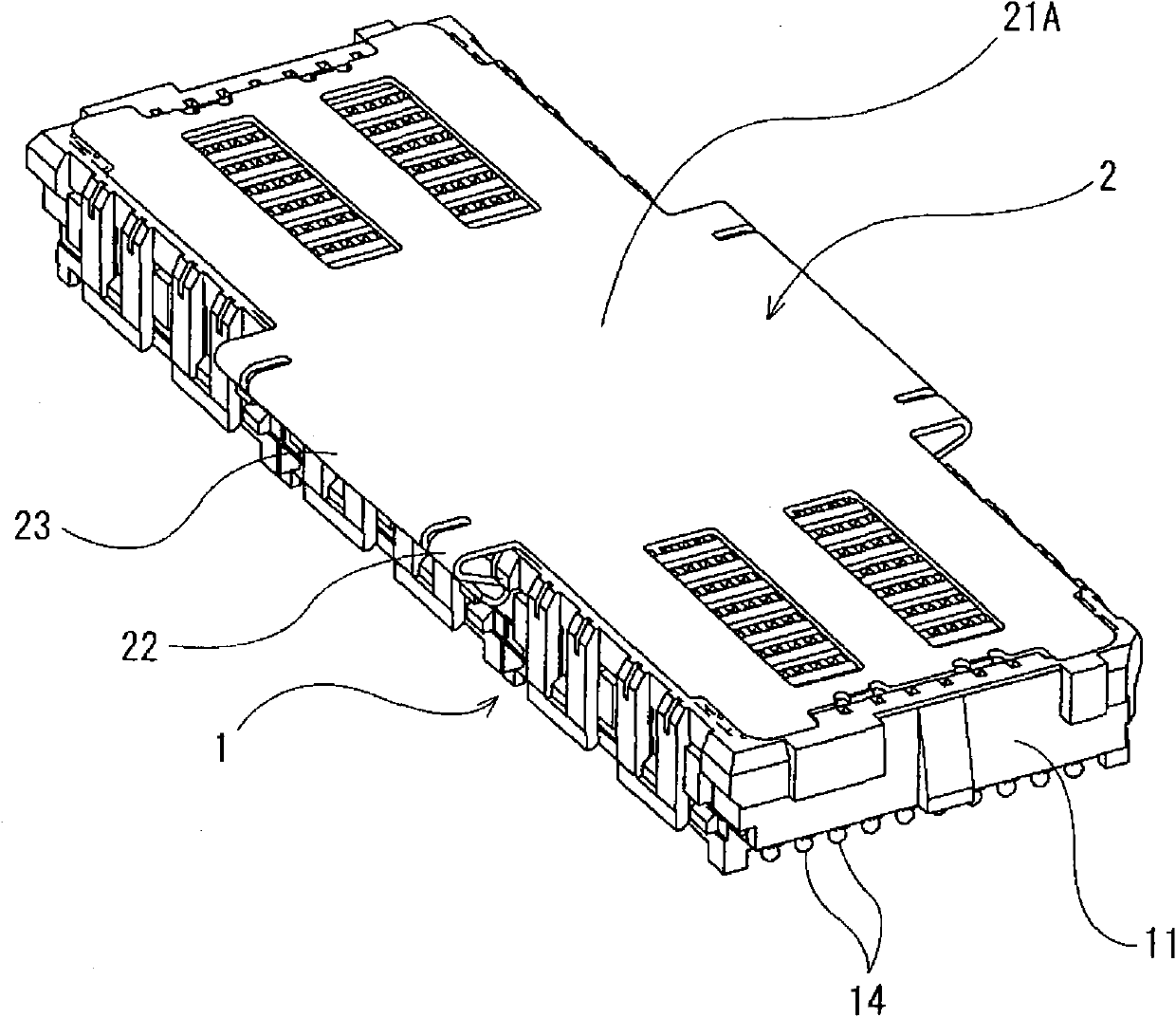

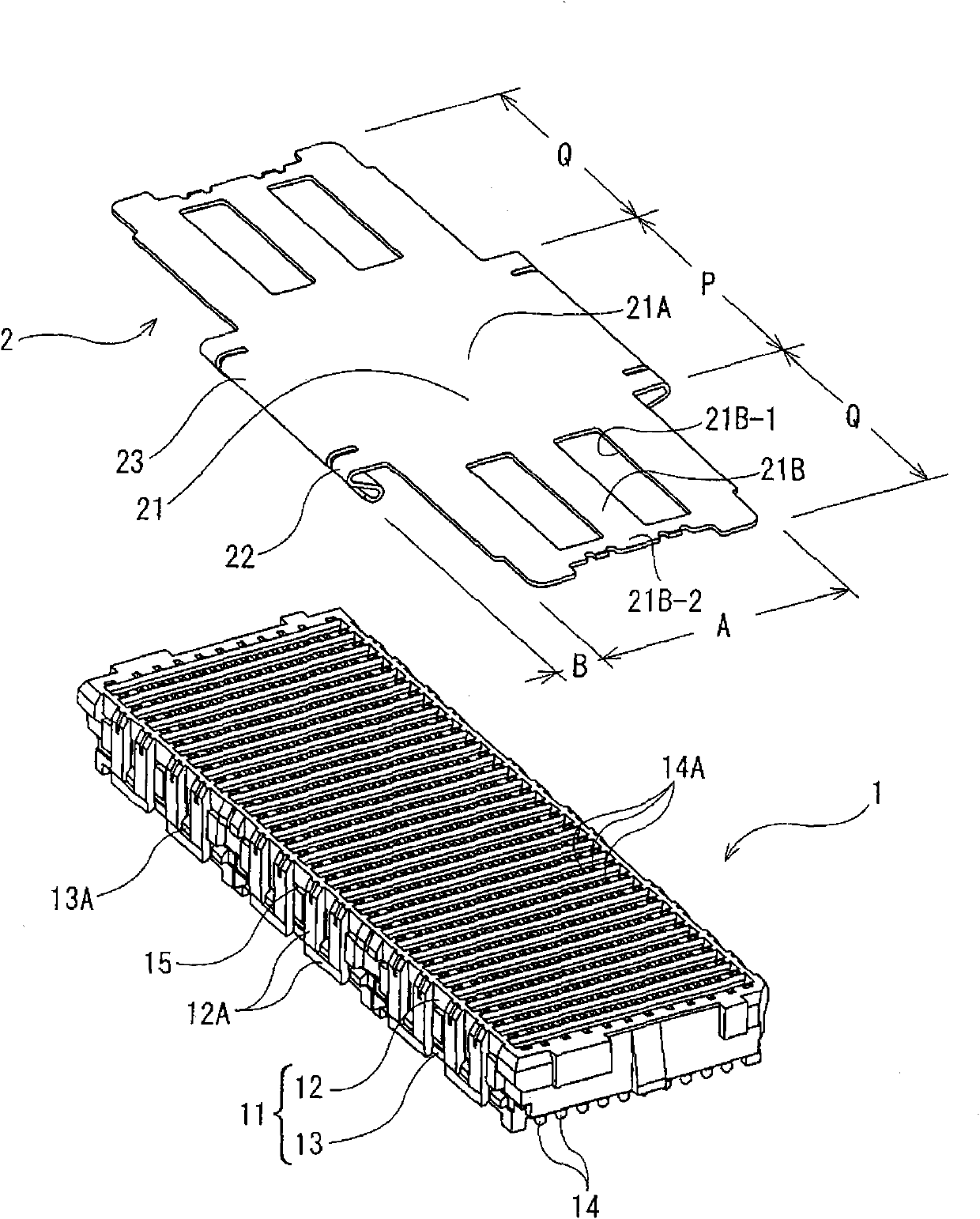

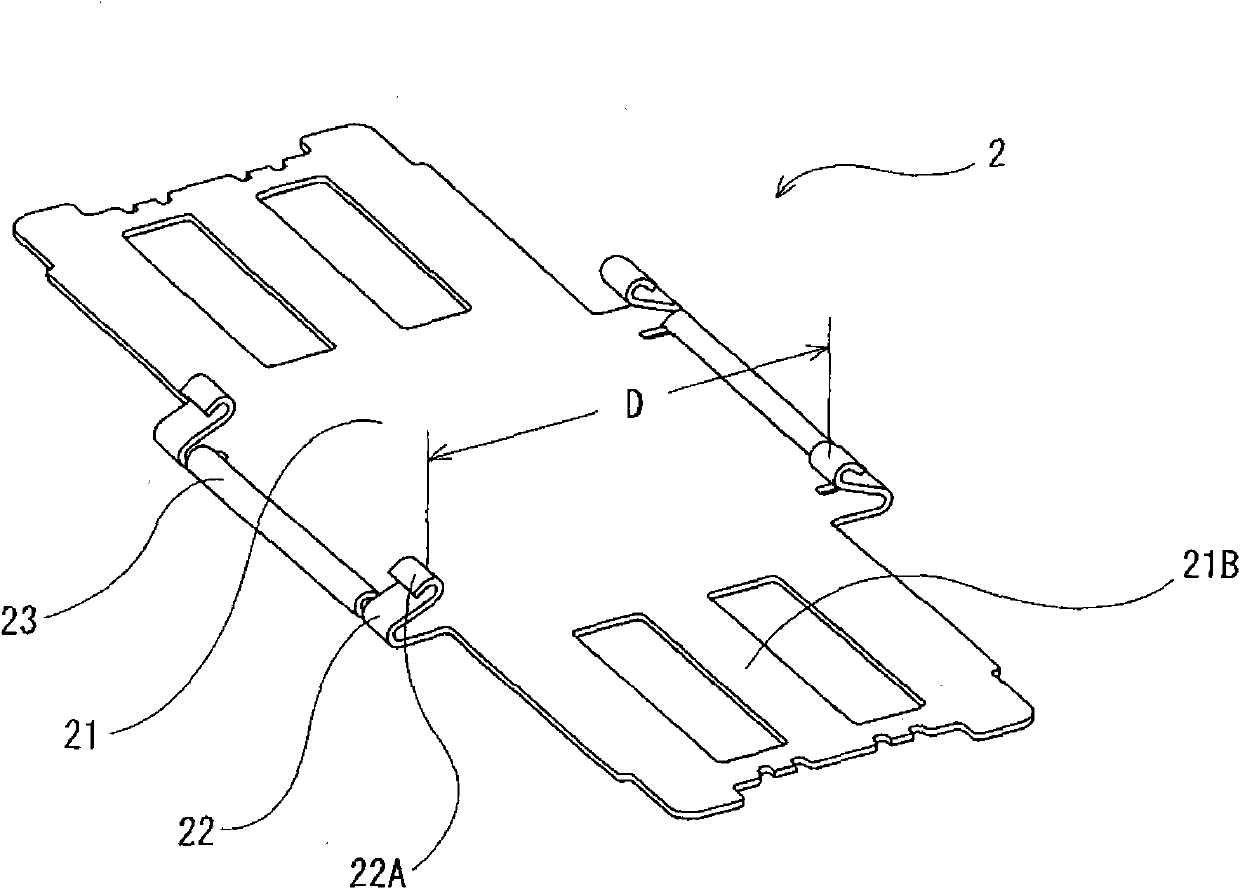

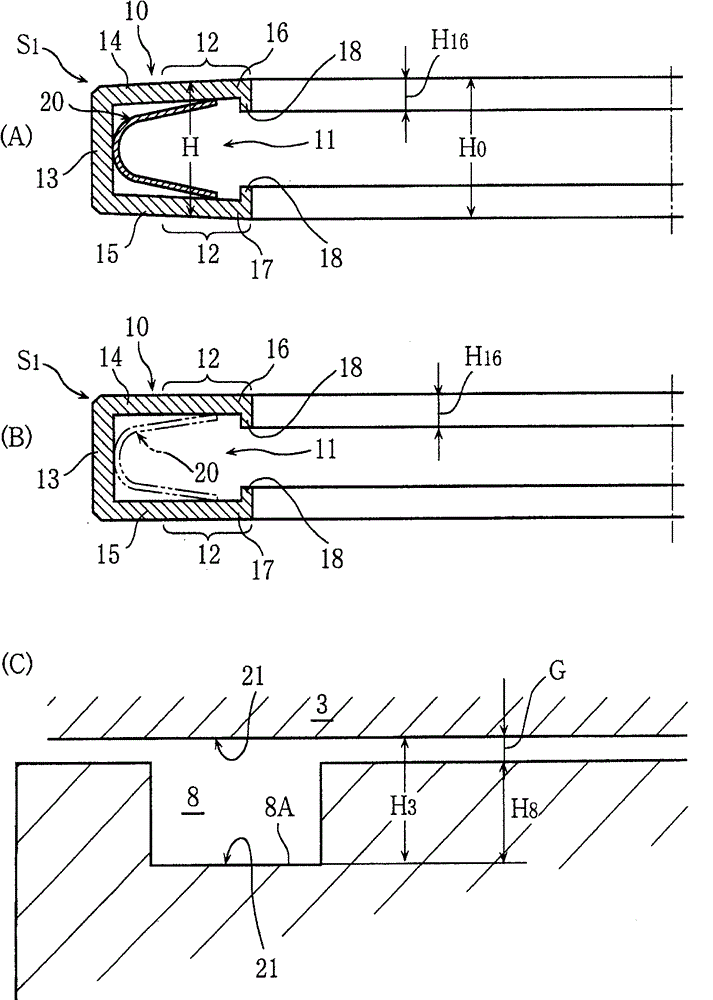

Electrical connector with suction member

ActiveCN102025049APrevent or limit bending deflectionCheap and easy to manufactureLine/current collector detailsFinal product manufactureSolderingElectrical connector

The present invention relates to an electrical connector having a suction member, which has an advantage of simple operation and can restrain warping and deformation of the housing in soldering connection. In the electrical connector which has the suction member (2) that is detachably mounted on an upper surface of the housing and can perform suction conveying with a suction mechanism, an upper surface of the housing (1) has width edges along a short side direction and a side edges along a long side direction. The suction member (2) is prepared through machining a sheet metal with flexibility. The suction member has a plate portion (21) that covers at least a part of the upper surface of the housing and an attachment portion (22) to attach the plate portion (21) to the housing at a middle position of the side edge of the housing in the long side direction. The plate portion forms an attachment region P as an area between both end portions of the attachment portion and a non-attachment region Q outside the attachment region and extending to an end portion in the long side direction. The non-attachment region has a free end portion at the end portion and has a deformable portion at least partially.

Owner:HIROSE ELECTRIC GROUP

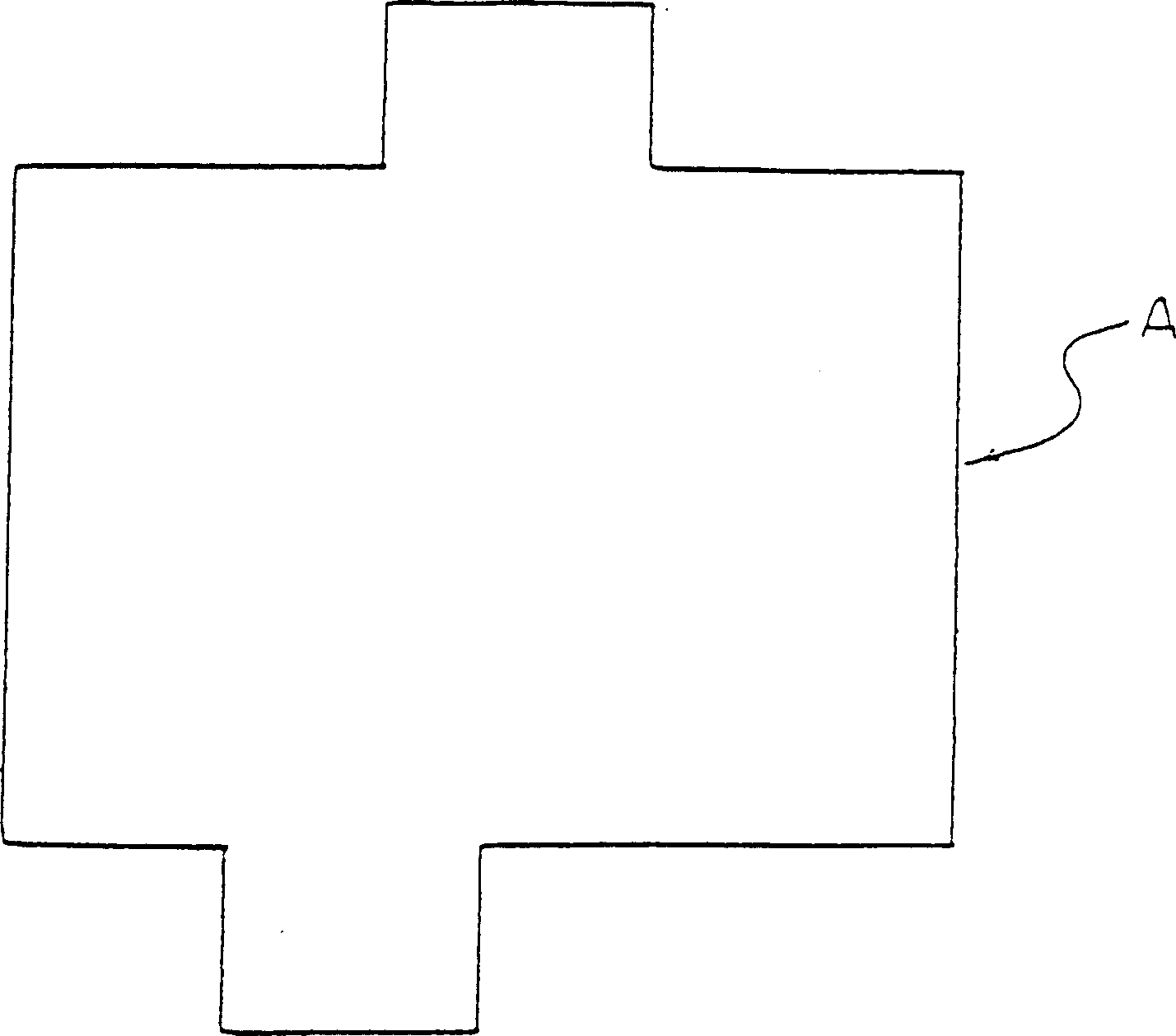

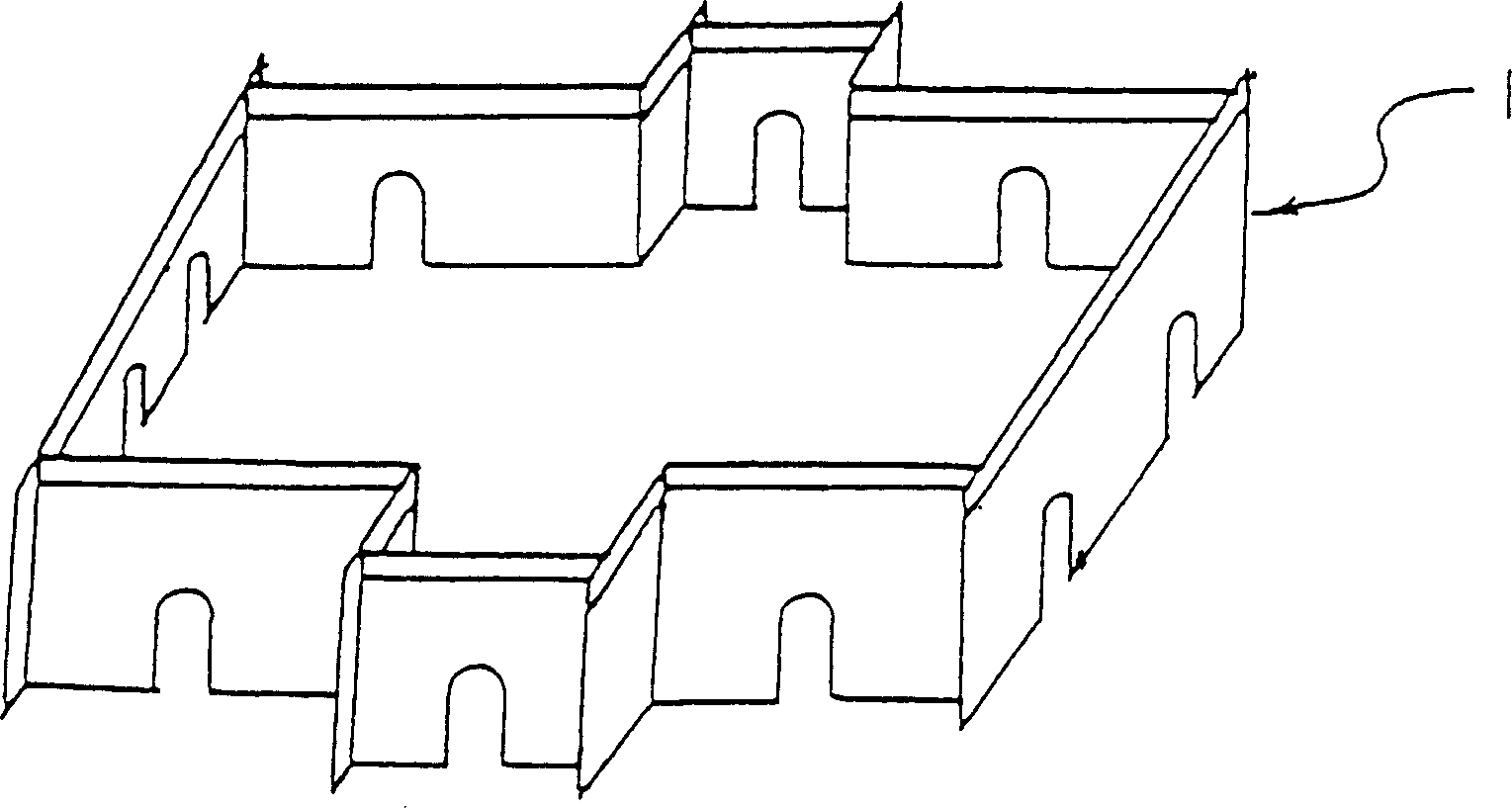

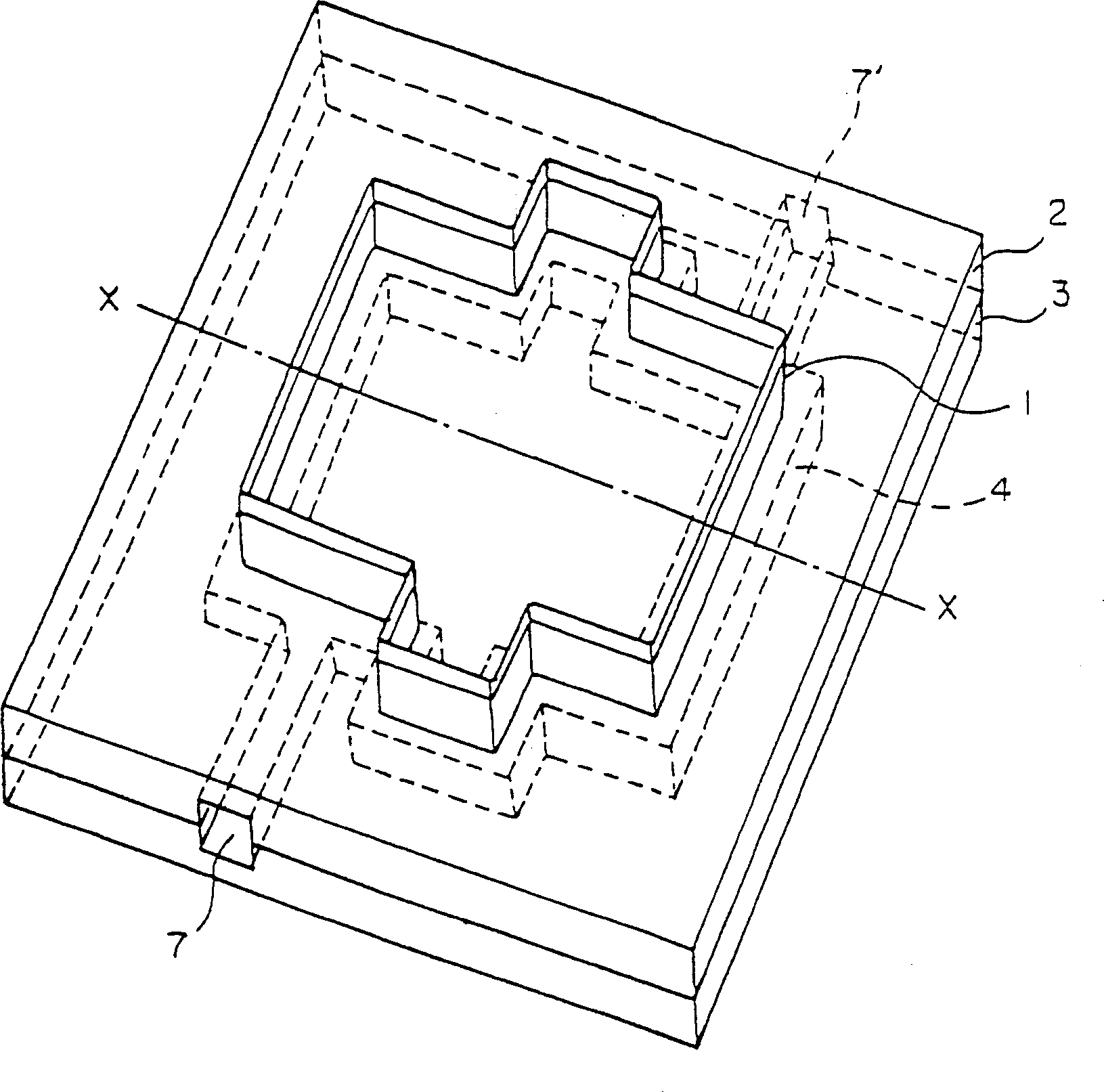

Blanking mould and manufacturing method thereof

InactiveCN1537708ACorrect punchingCorrectly and securely fastenedCleaning using gasesMetal working apparatusProduct gasEngineering

Provided is a blanking die which causes no slack of a fixed punch and carries out exact blanking even if a large number of sheetlike materials are blanked at a high speed, and also to provide a blanking die which easily separates products obtained by blanking the sheetlike materials from the scraps, and causes no pollution problems even if the disposal by incineration is carried out. Base materials 2, 3 of the blanking die have spaces 4 surrounding the punch 1. Resin is charged into the spaces and is solidified to fix the punch 1. Further, the spaces 4 are filled with gas, and the base material 2 is provided with a plurality of gas flowing-out holes. As a result, the products and the scraps are easily separated by flowing-out the gas through the gas flowing-out holes.

Owner:TAKAHASHI KEISEI

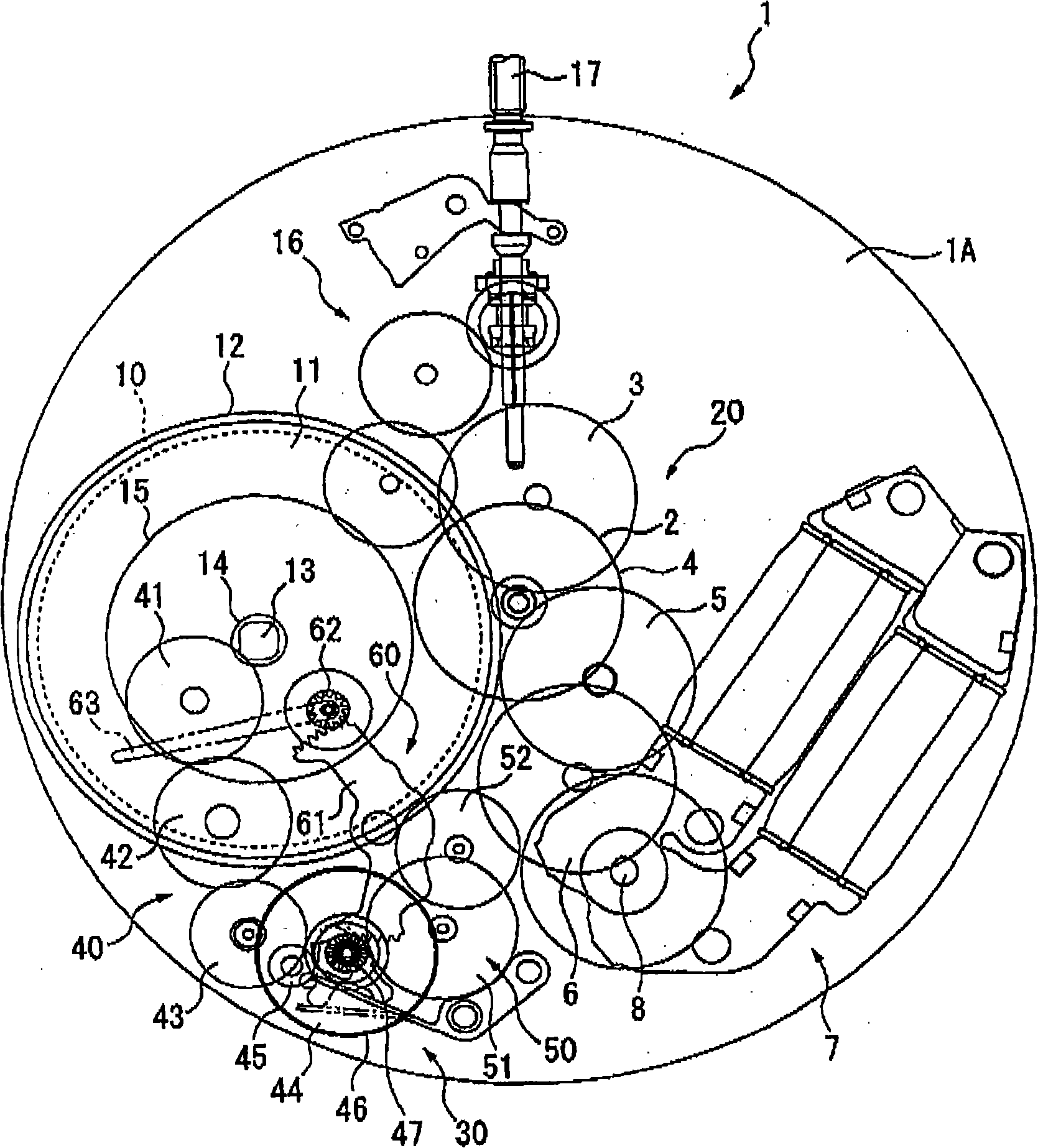

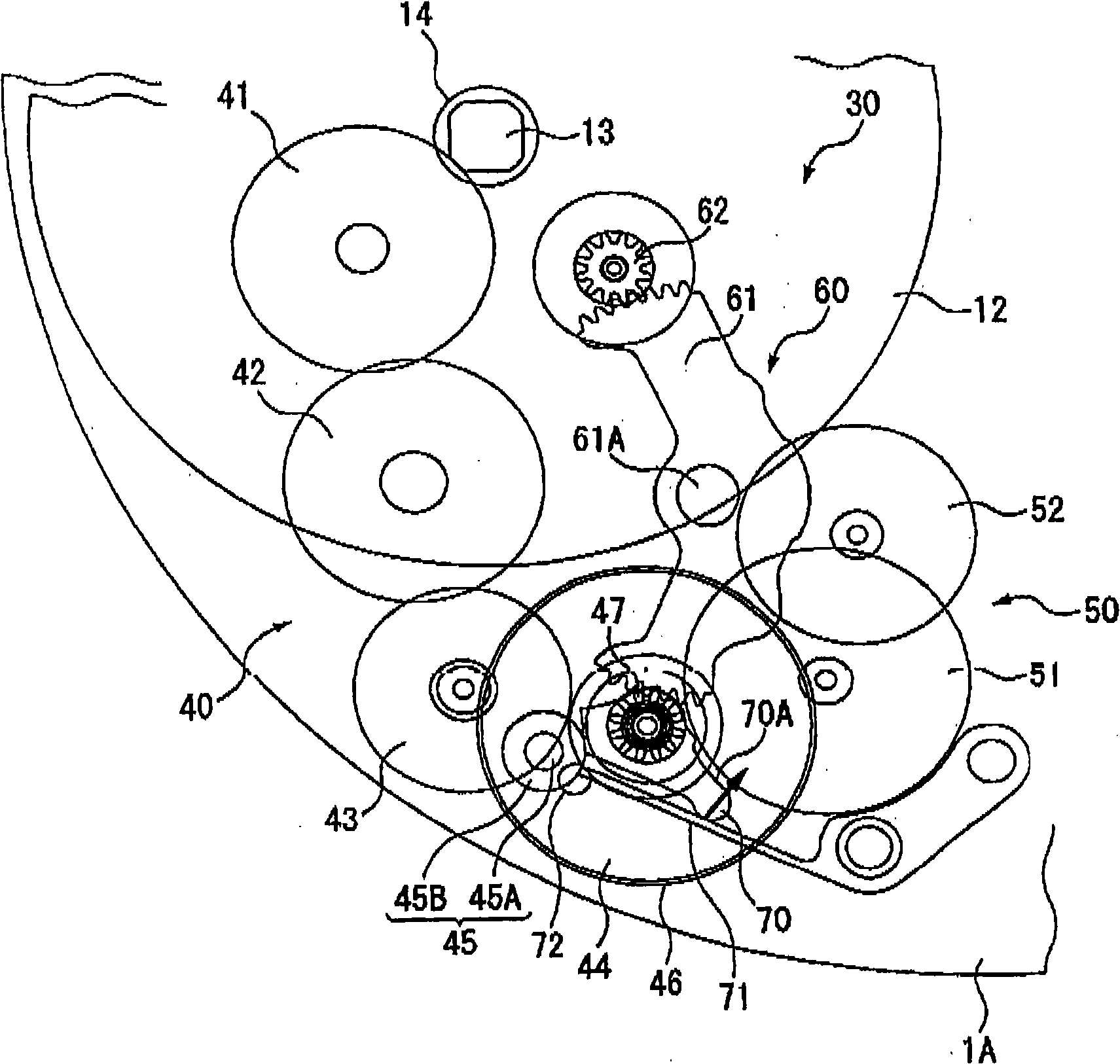

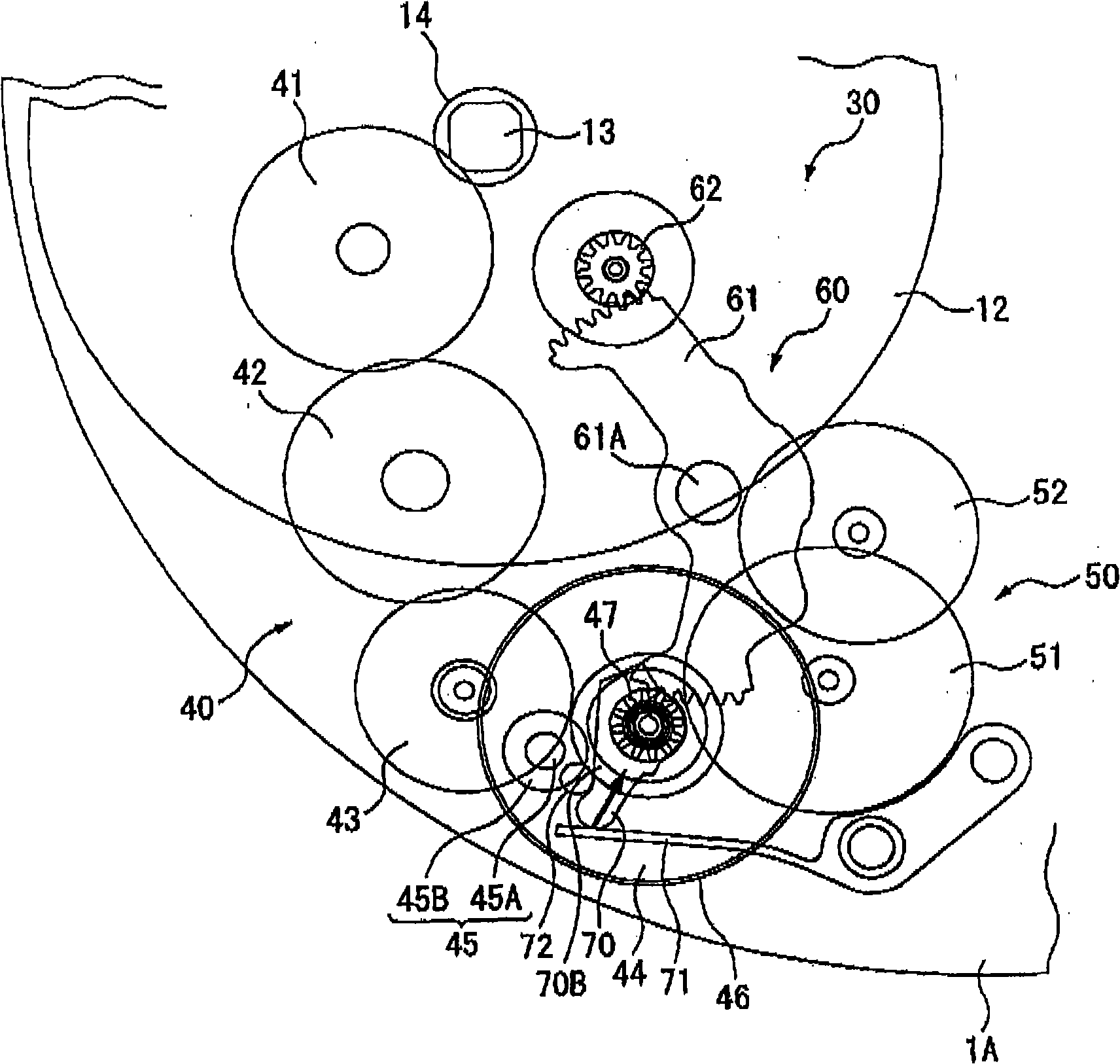

Timepiece

InactiveCN101276199AHigh torqueReduce generationElectric windingClock driving mechanismsMainspringControl theory

A timepiece having an output wheel that is rotated by torque output from the mainspring, a lever that pivots synchronously to the output wheel, and a pressure member that pushes the lever. The pressure member pushes the lever so that the output torque of the output wheel increases as the mainspring unwinds.

Owner:SEIKO EPSON CORP

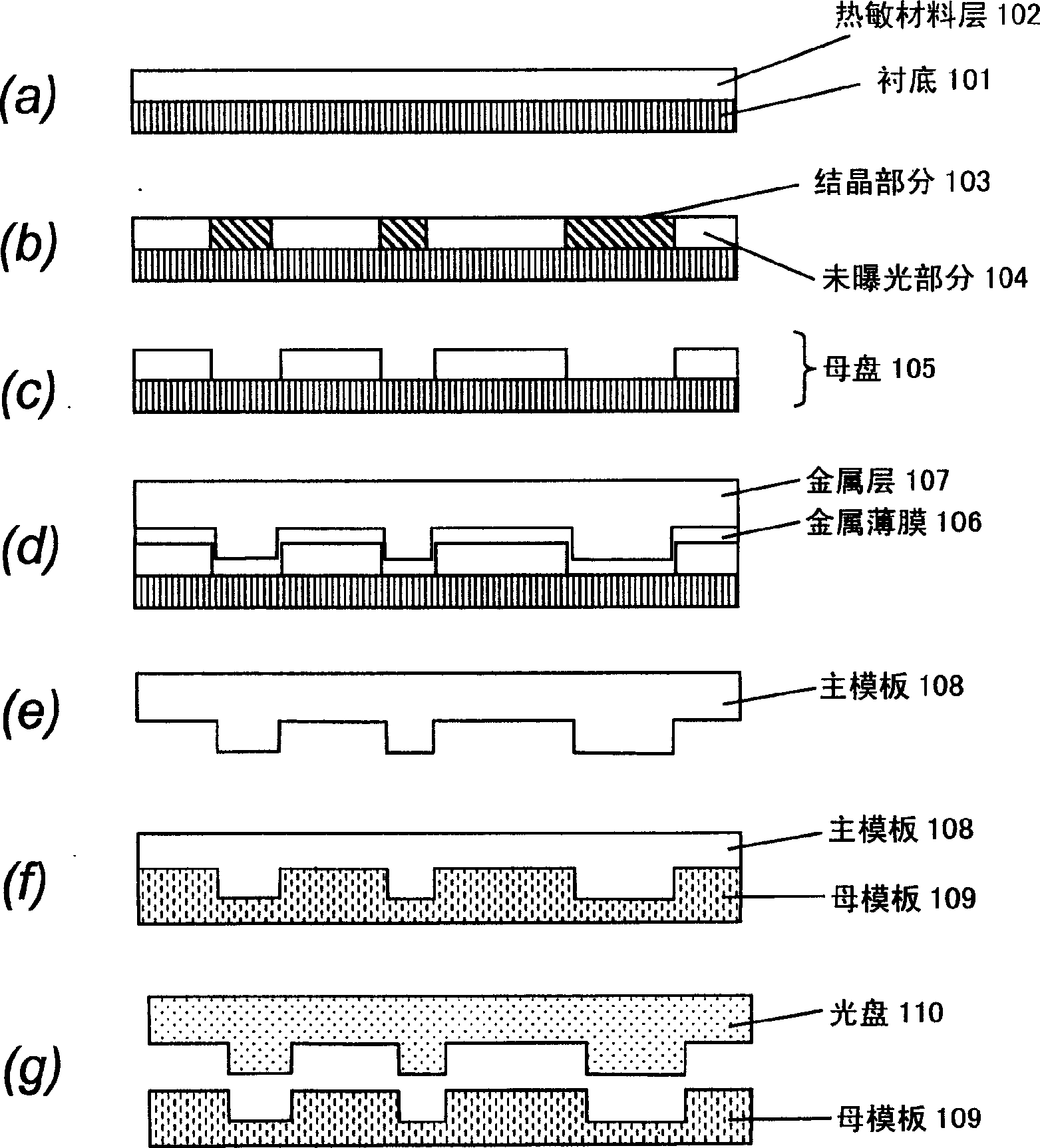

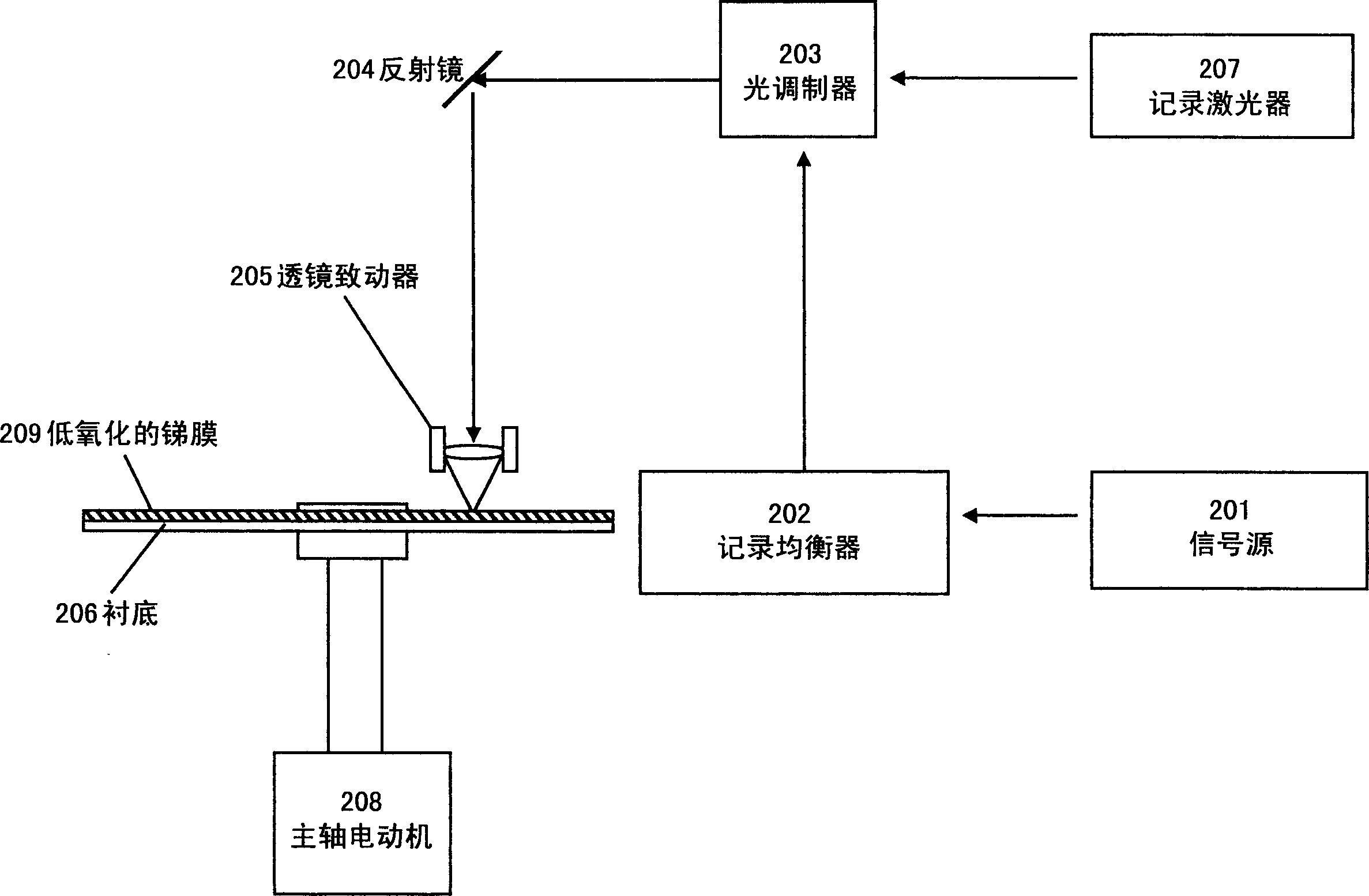

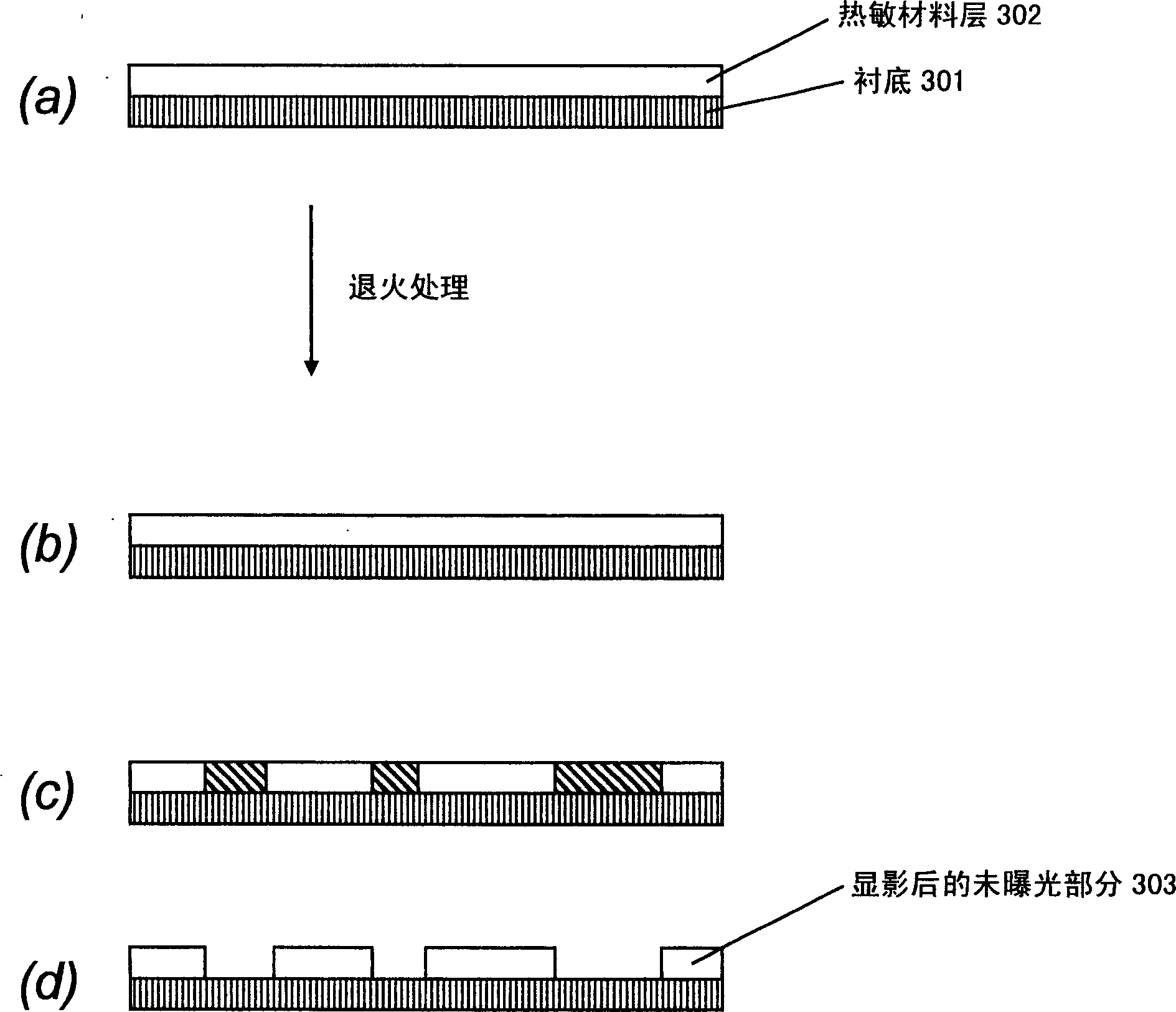

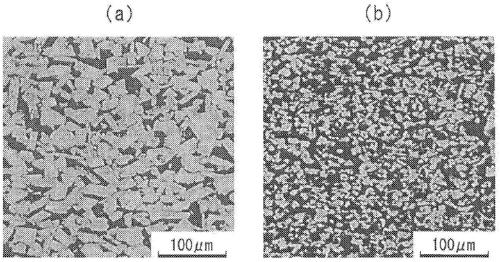

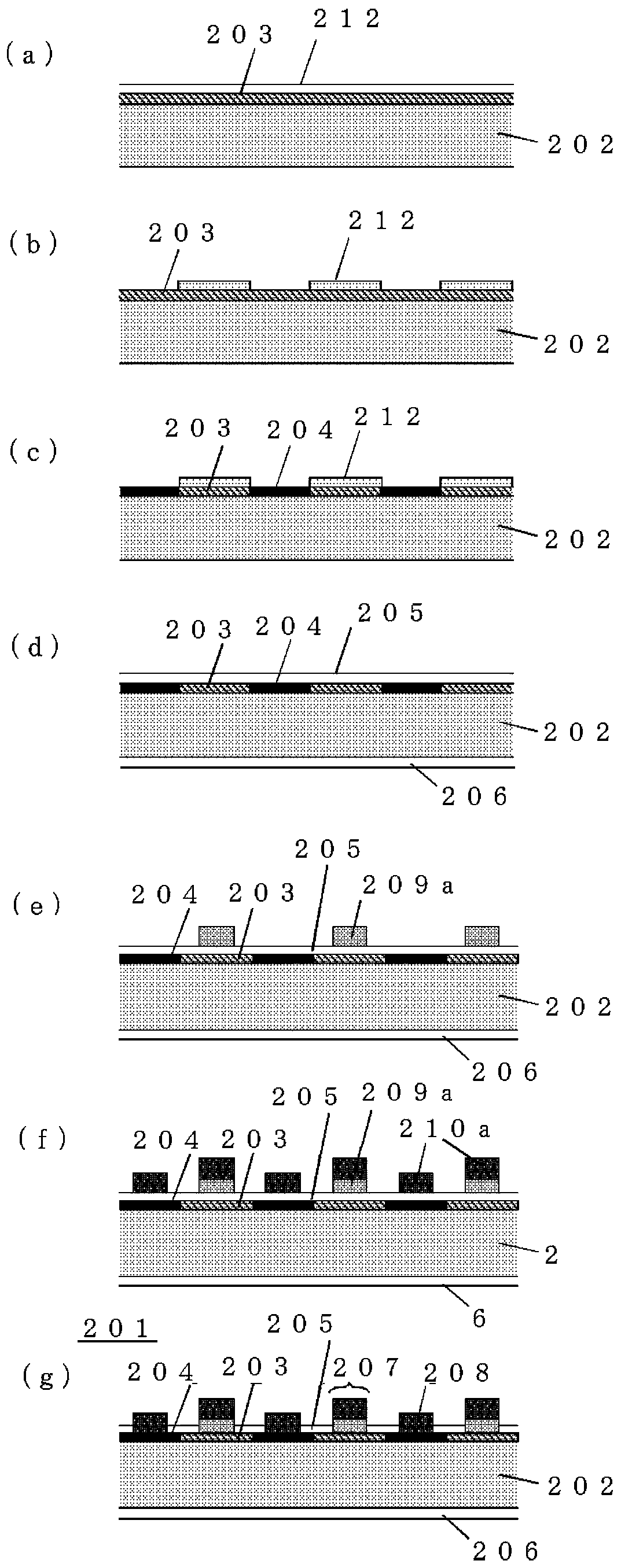

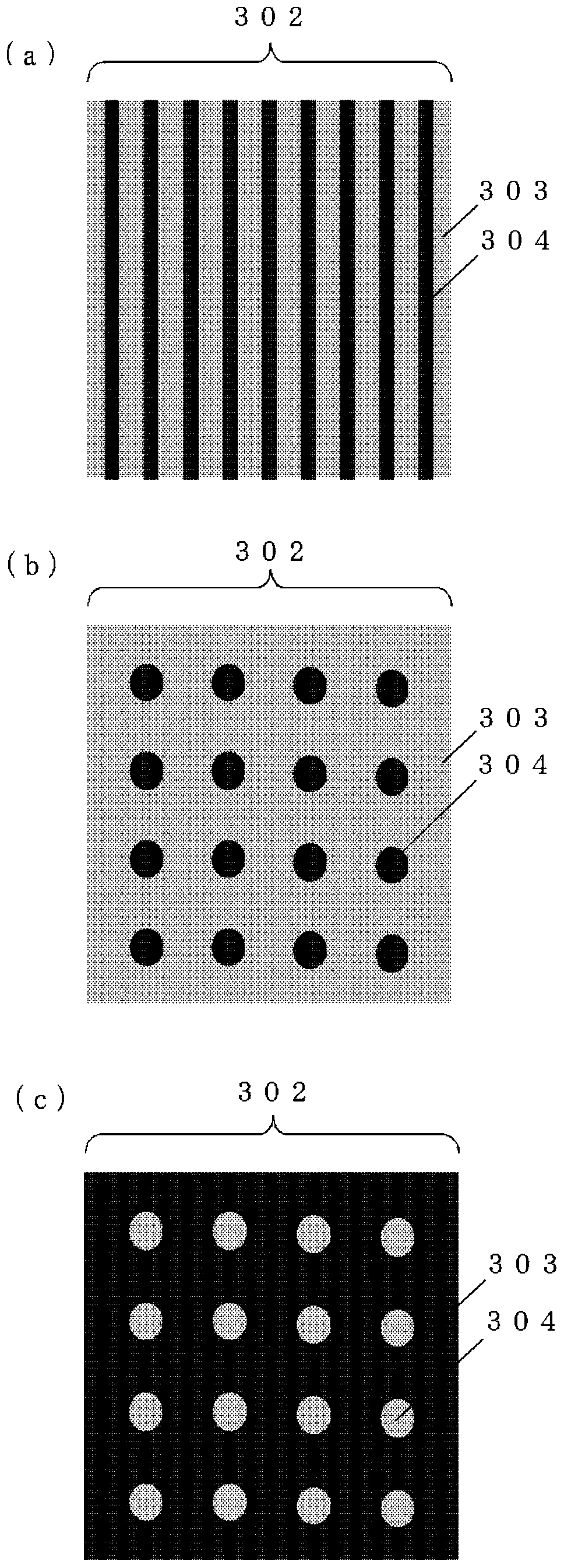

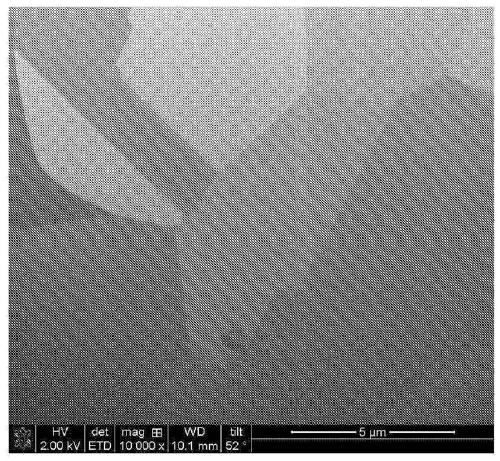

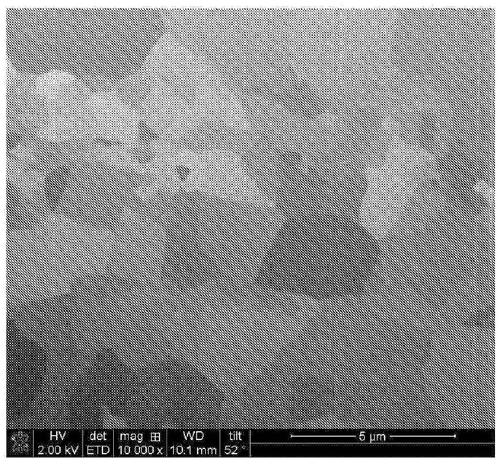

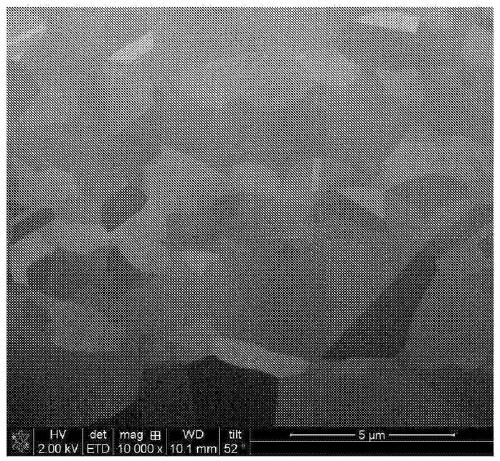

Method for producing a master disk,stamper and recording medium,and master disk, stamper and recording medium

InactiveCN1591630AContribute to high densityCheap and easy to manufactureRecord information storageOptical record carrier manufactureHeat sensitiveOptoelectronics

Owner:PANASONIC CORP

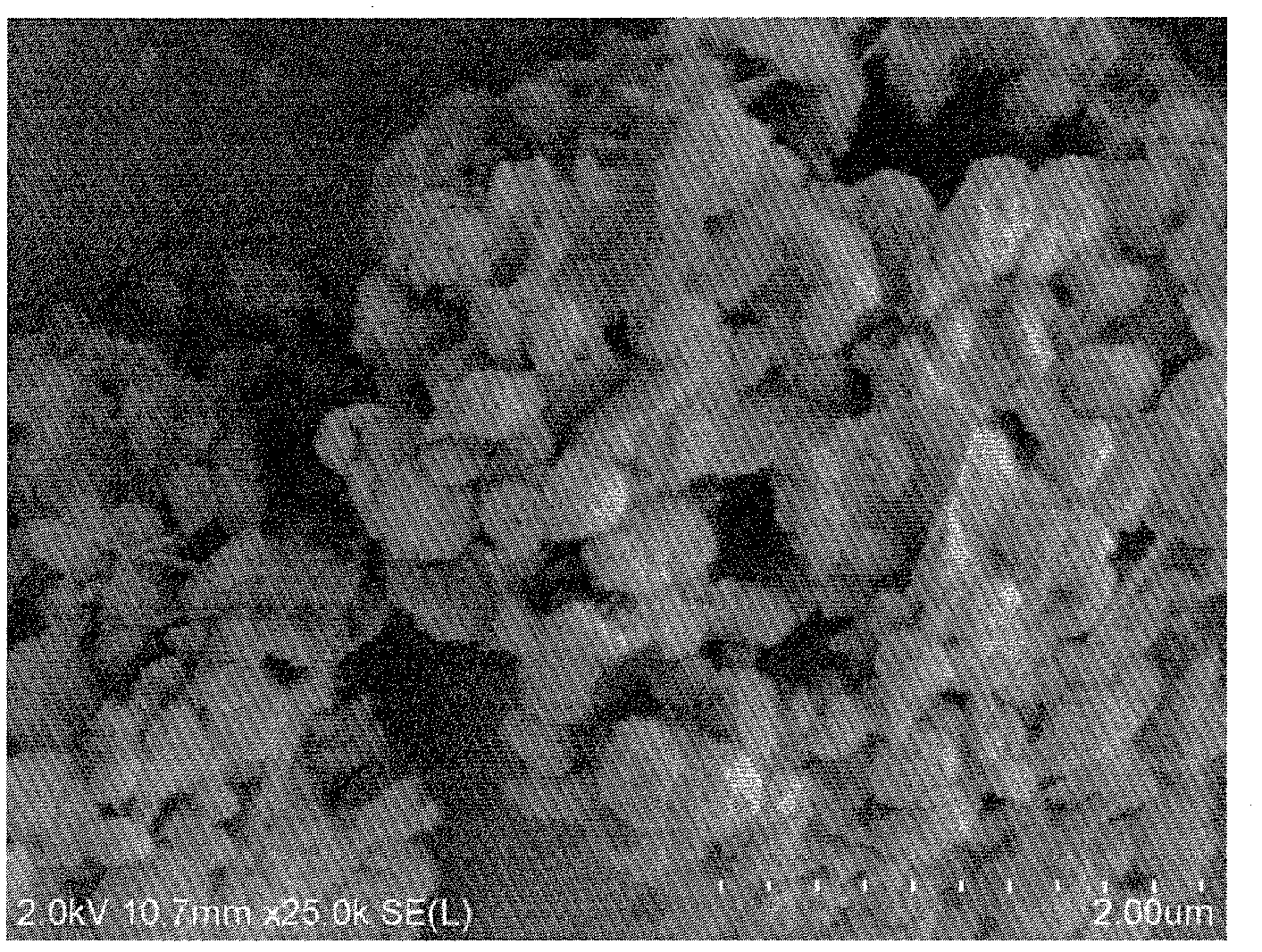

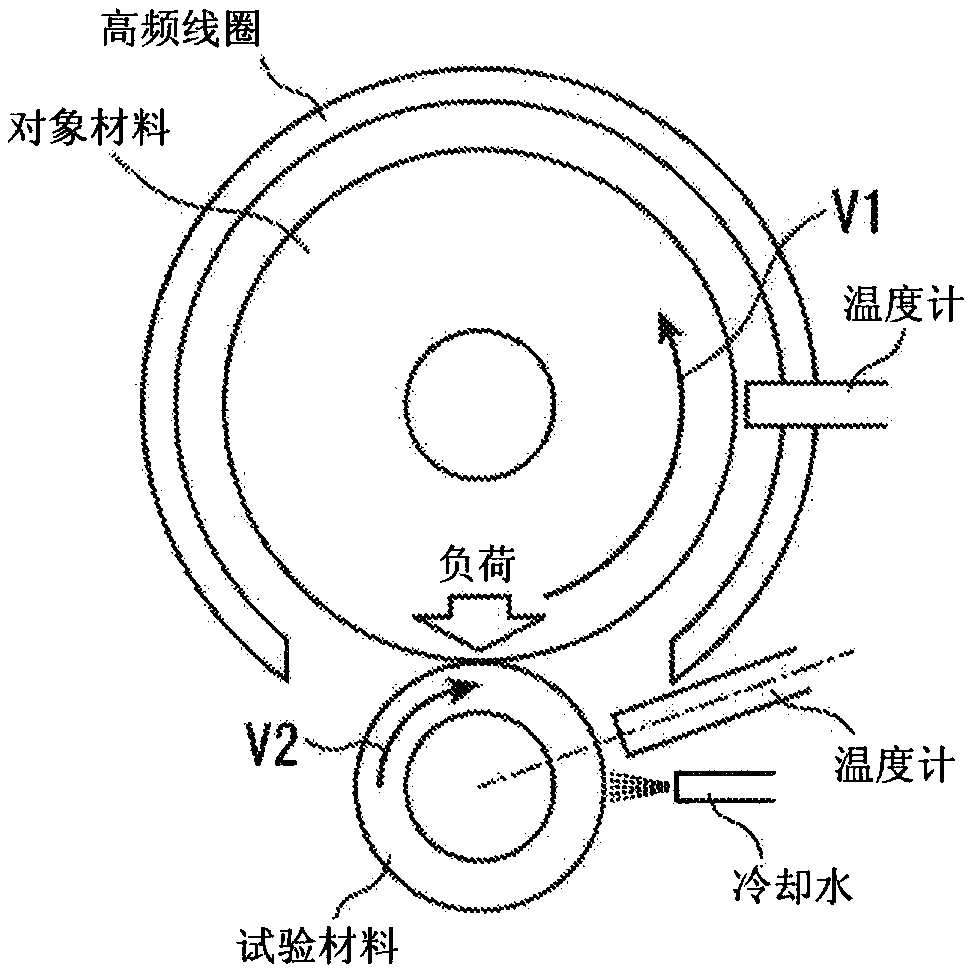

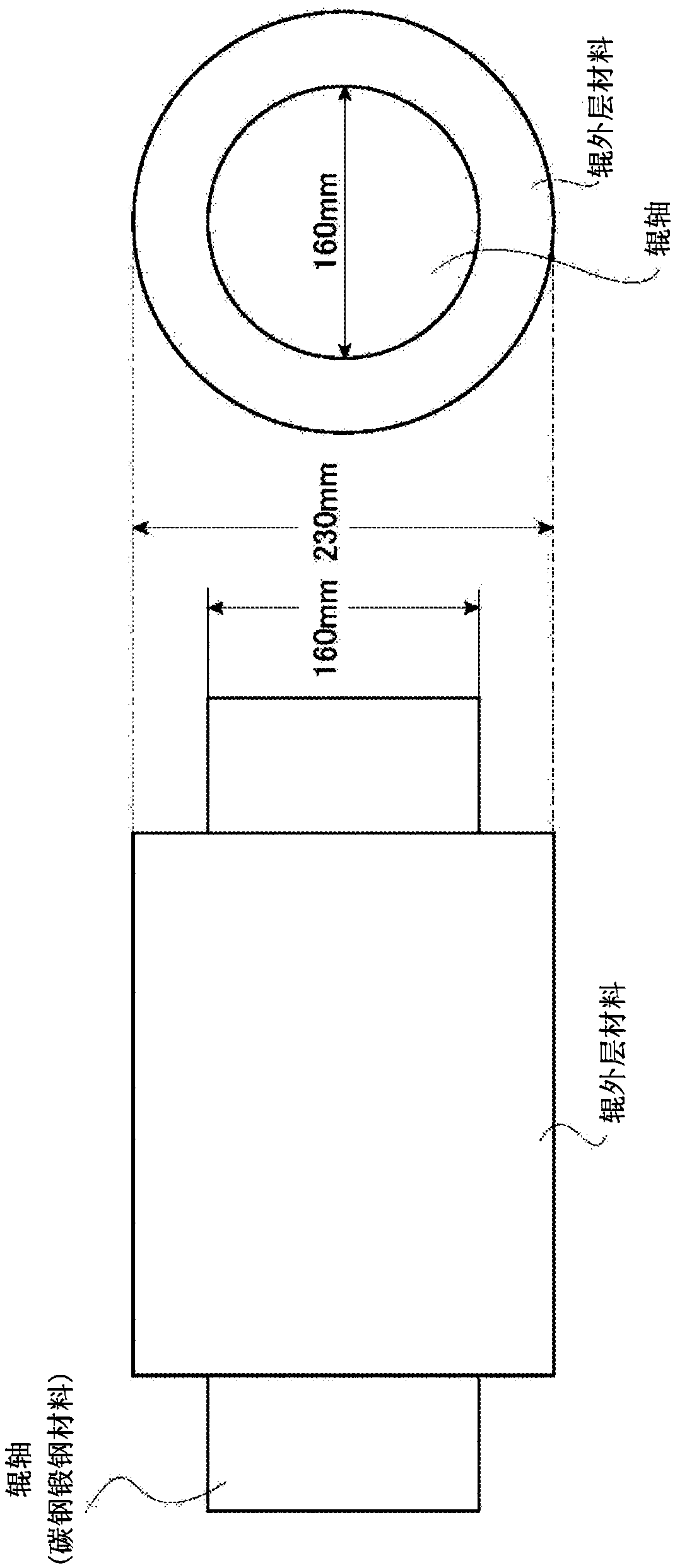

Roll outer layer material for rolling, and composite roll for rolling

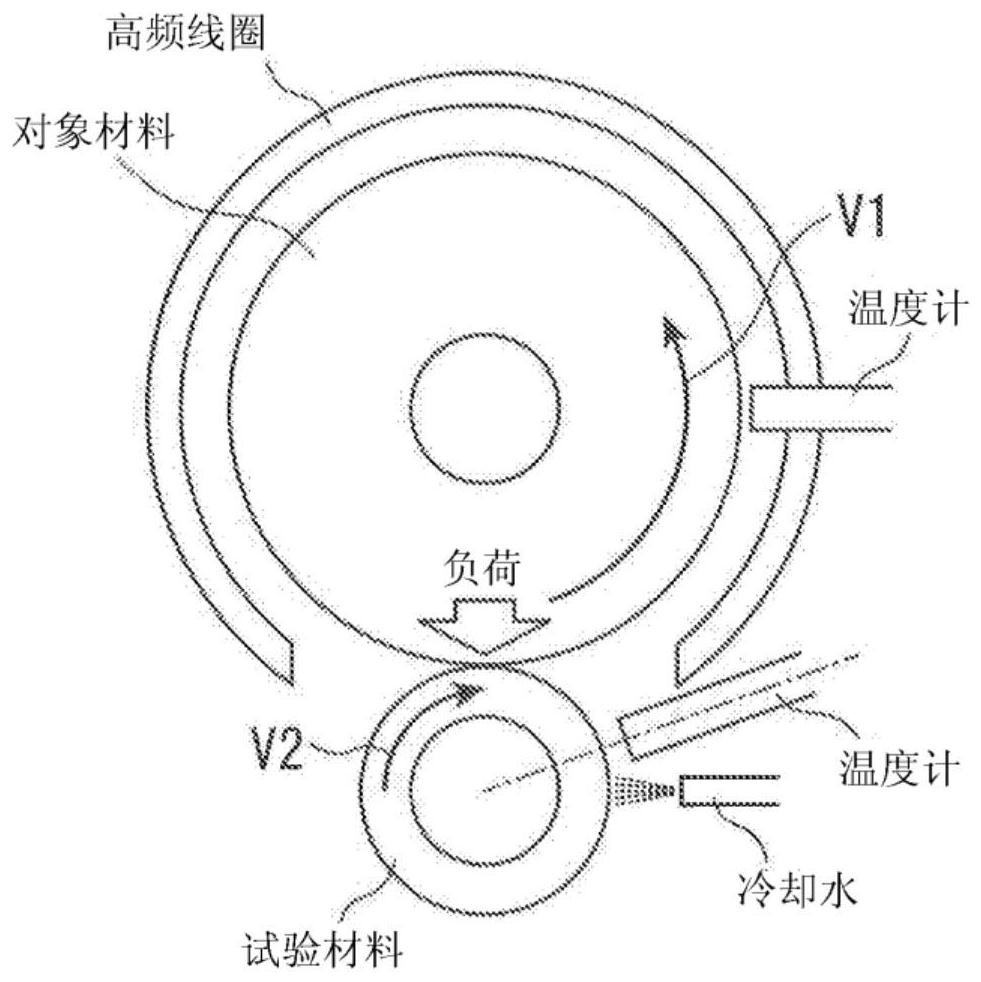

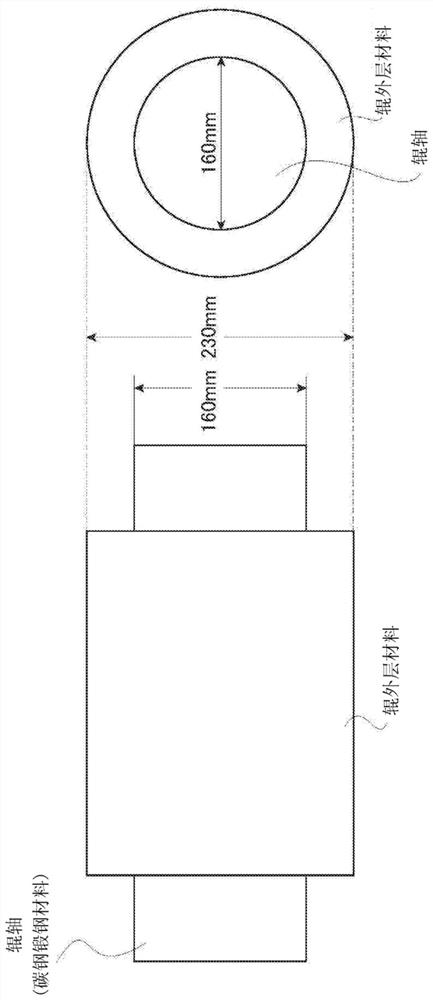

ActiveCN109641251ACheap and easy to manufactureImprove wear resistanceRollsMetal rolling arrangementsMaximum diameterImpurity

Provided are a roll outer layer material and a composite roll for rolling that have remarkably improved abrasion resistance. A roll outer layer material that has a W-Co-based alloy composition: that is a graded composition in which W content decreases in the radial direction from an outer circumferential side toward an inner circumferential side; and that, at an outer layer material surface that is located at a maximum diameter during rolling, contains, by mass%, 25%-70% of W, 5%-45% of Co, 0.6%-3.5% of C, 0.05%-3% of Si, 0.05%-3% of Mn, and 1%-15% of Mo, the remainder being unavoidable impurities. The roll outer layer material is preferably produced by centrifugal casting.

Owner:JFE STEEL CORP

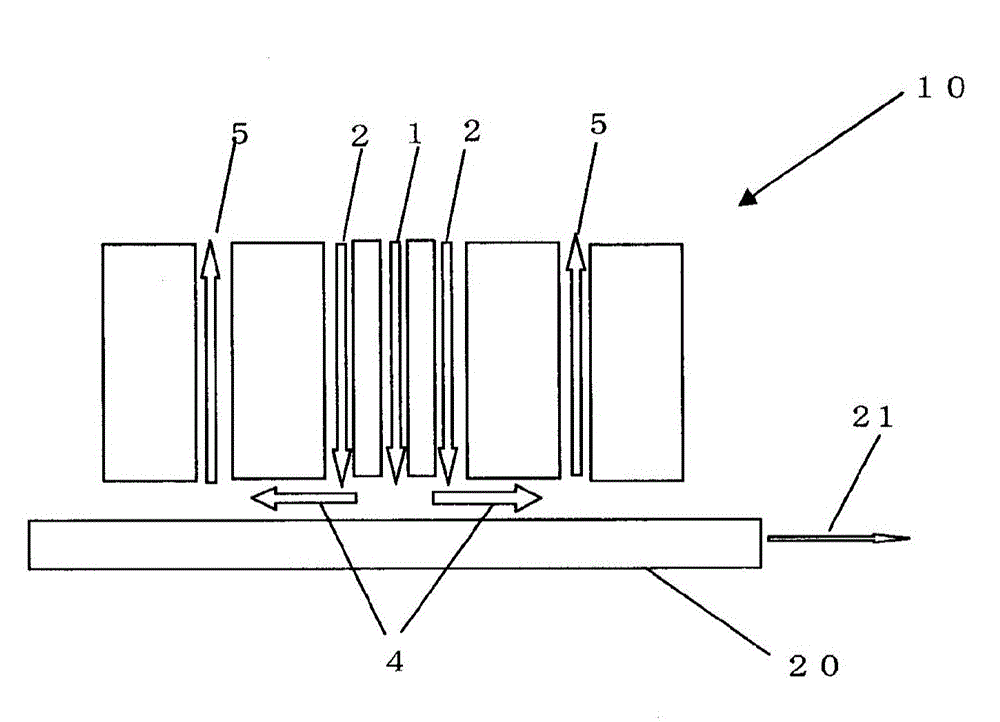

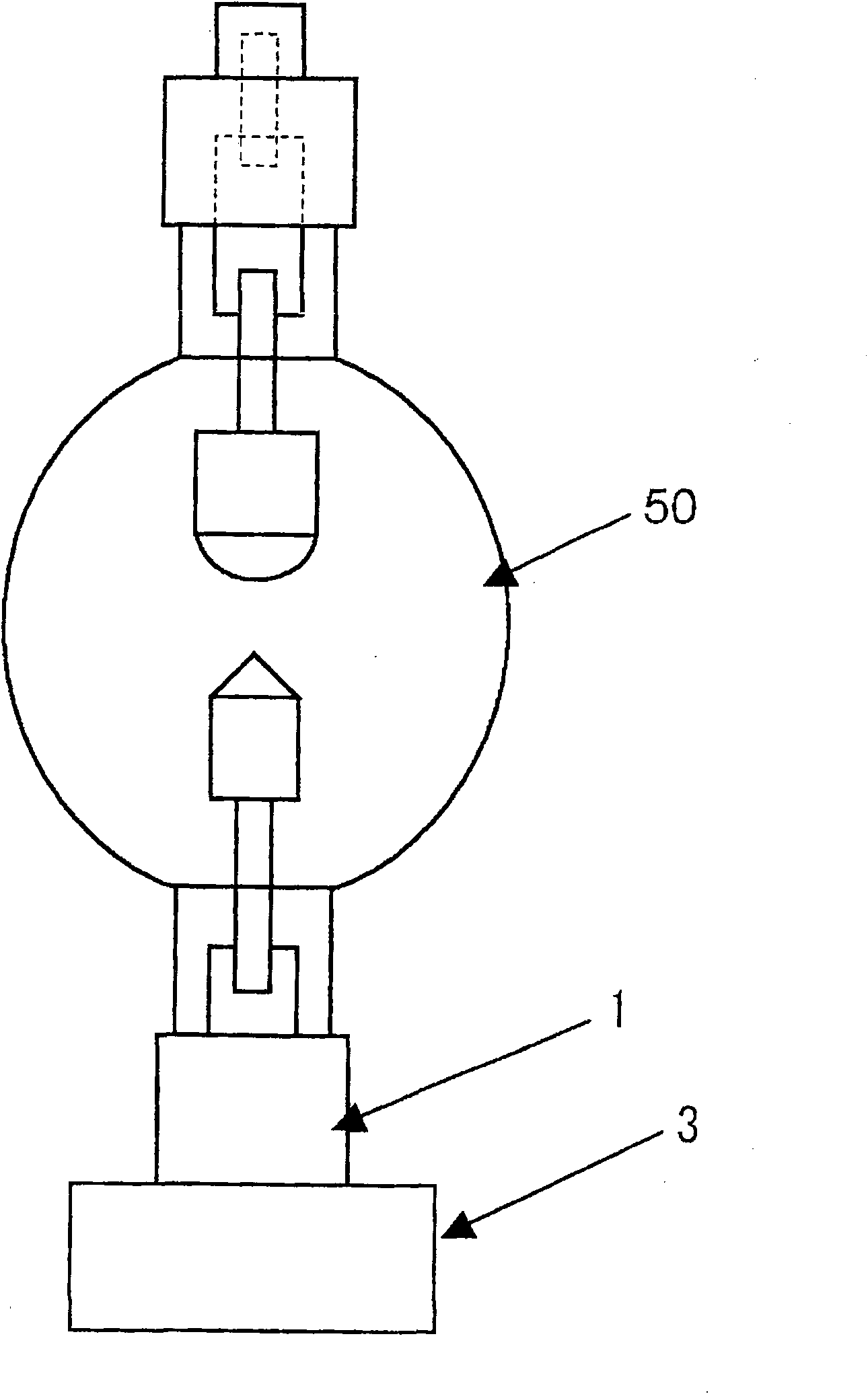

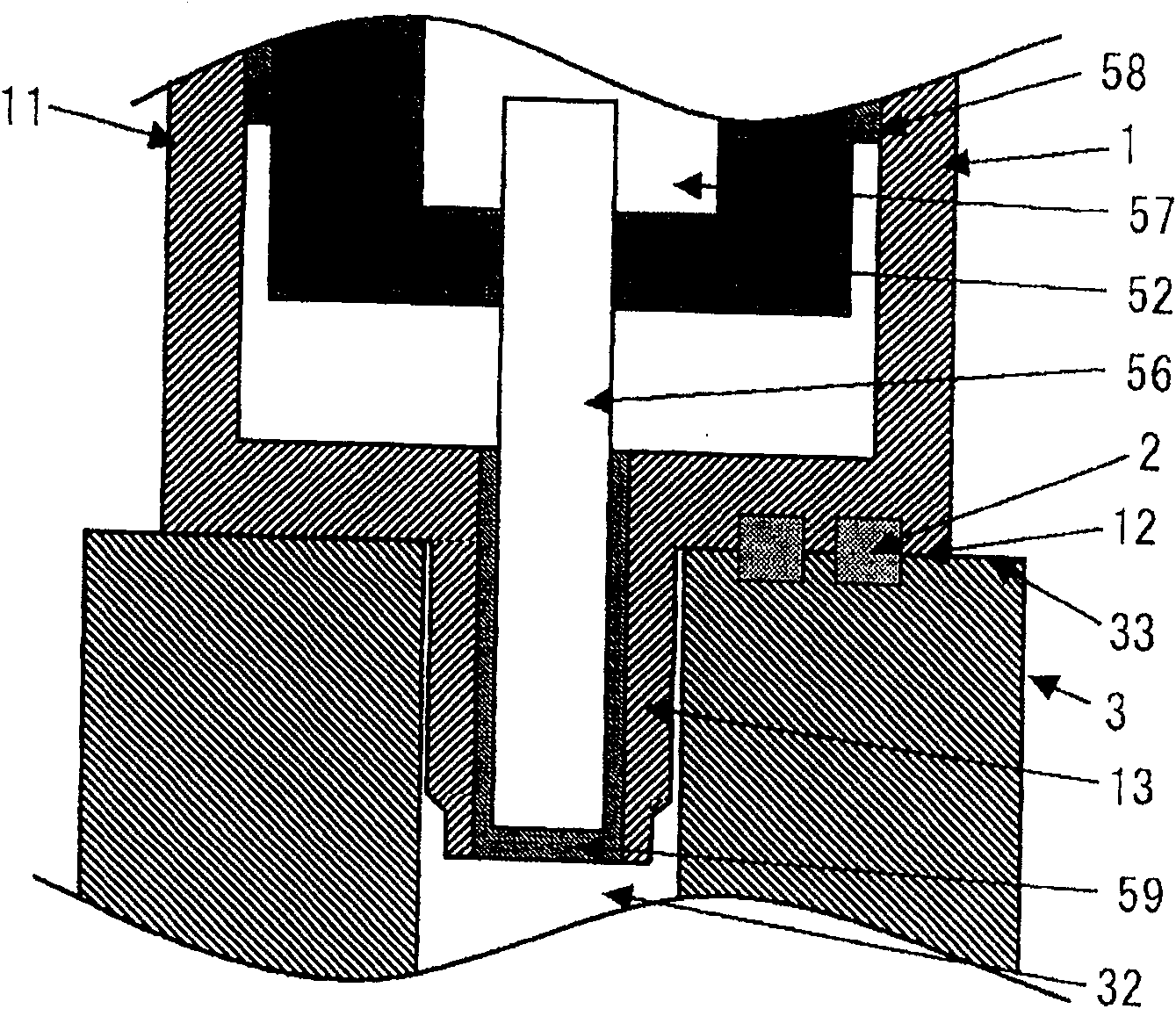

Light source device

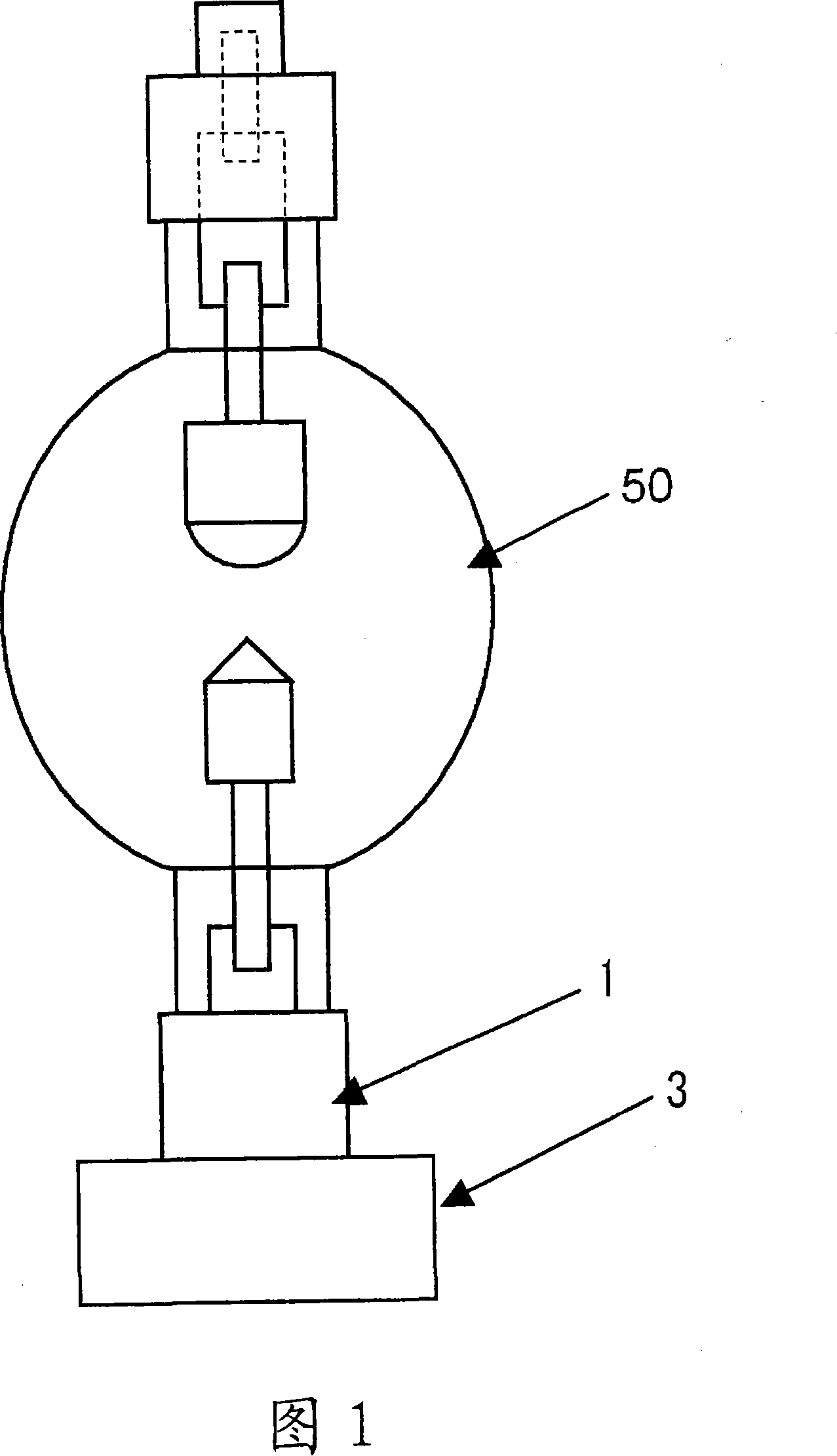

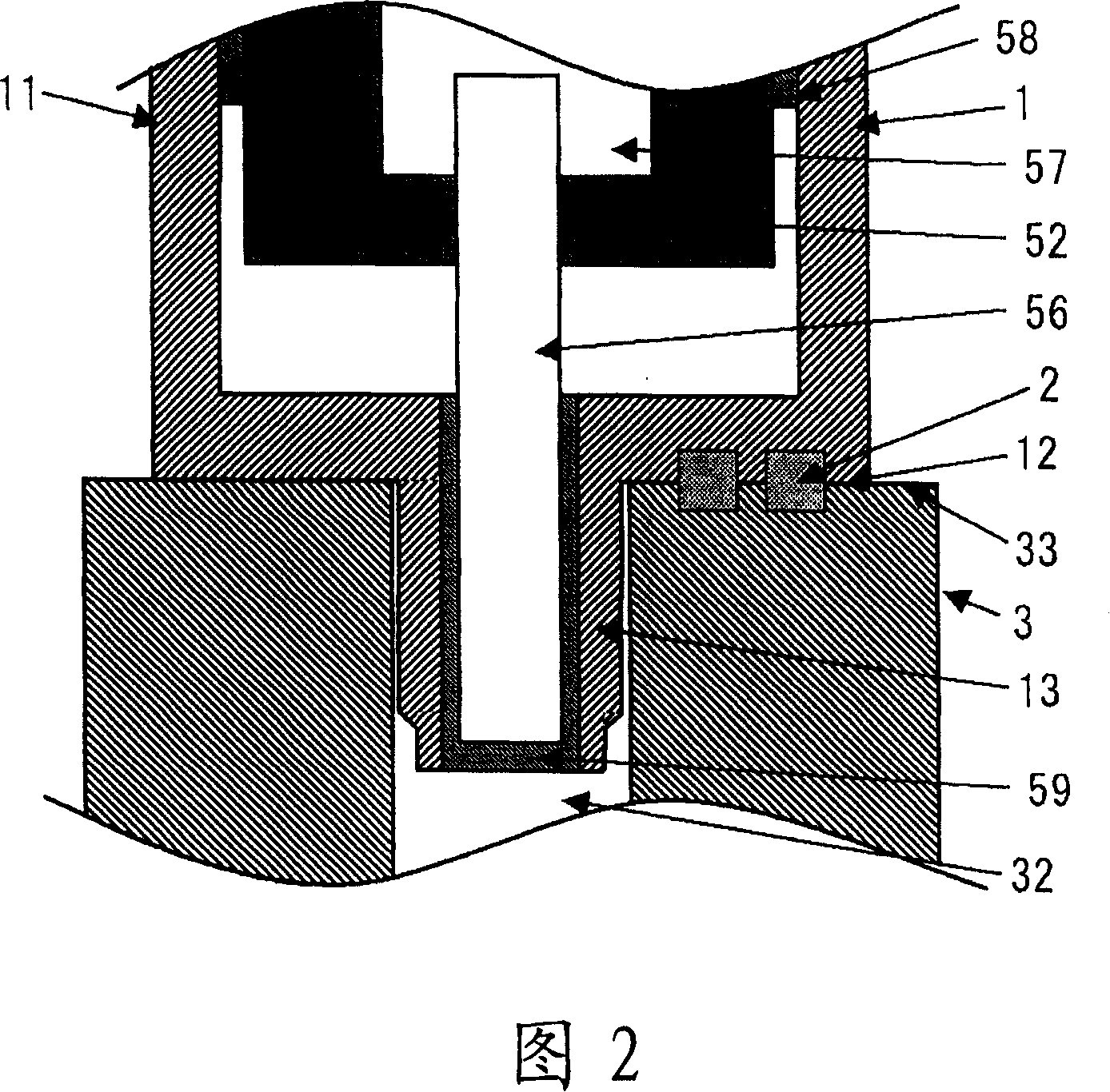

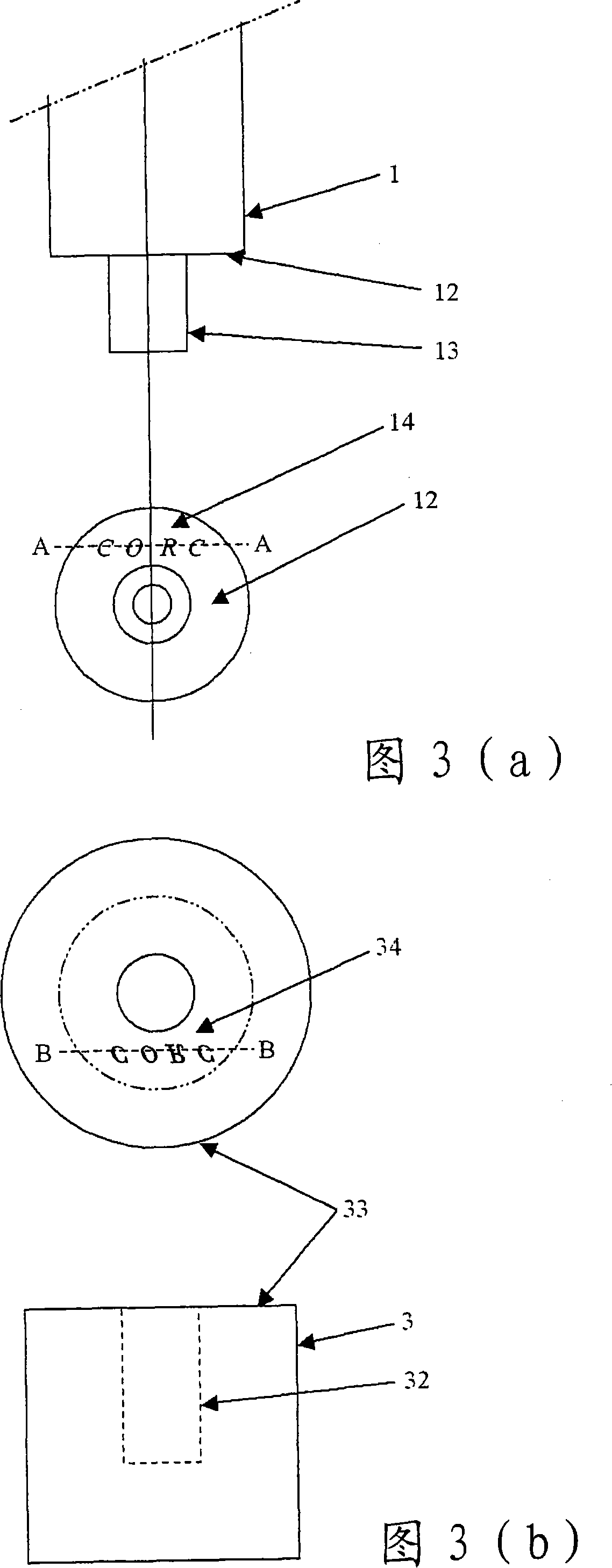

ActiveCN101123163ACheap and easy to manufactureEasy to manufactureCoupling device connectionsElectric discharge tubesGas-discharge lampPunch press

The invention provides a light source device which can produce a lamp head and a lamp head seat structure correctly installed on the light source device after confirming the suitability of a discharge lamp. Concave portions are formed on the lamp head structure body and the lamp seat, which are mirror symmetry. The concave portion can be accurately produced by the laser processing. A punch is used to die cut the conducting plate with a thickness equal to the depth summation of the concave portions. A block matched with the concave portion is produced and the block is embeded into a second concave portion. If the lamp head structure body is inserted into the lamp head seat, the block embeded in the second concave portion of the lamp head seat is embeded with the first concave portion of the lamp head structure body. The block can position the lamp head structure body and the lamp seat and fix two parts easily and accurately.

Owner:ORC MFG

Process for production of phosphoric acid compound, and process for production of secondary battery

InactiveCN102666374AComposition is easy to controlCheap and easy to manufactureCell electrodesPhosphorus compoundsChemical compositionChemical compound

Disclosed is a process for producing a phosphoric acid compound, which enables the production of olivine-type crystalline particles of a phosphoric acid compound having excellent properties and excellent reliability at low cost and in a simple manner. Particularly disclosed is a process for producing a phosphoric acid compound useful as a positive electrode material for a secondary battery. Solid particles of a compound (Y) having a chemical composition represented by the formula AxMyP3Oz (wherein element A represents at least one element selected from the group consisting of Li and Na; element M represents at least one element selected from the group consisting of Fe, Mn, Co and Ni; and N which represents the valency the element M, x and y respectively fulfill the requirements represented by the formulae +2<N<=+4, 0<x<4 and 0<y<3) and a compound (Z) containing the element M are mixed together so that the resulting product has a chemical composition represented by the formula AaMbPOw (wherein 0<a<2 and 0.8<b<1.2), and the resulting product is agitated while grinding and heated in an inert gas or a reducing gas to cause a solid-phase reaction. In this manner, particles of a phosphoric acid compound (X) having a chemical composition represented by the formula AaMbPOw (wherein A is derived from the compound (Y); and M is derived from the compounds (Y) and (Z)) can be produced.

Owner:ASAHI GLASS CO LTD

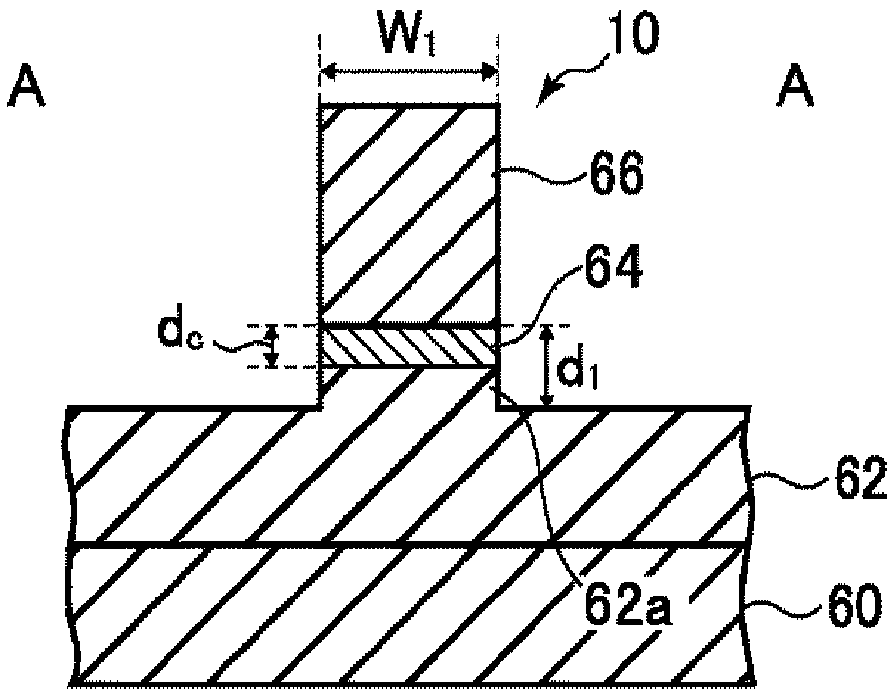

Optical element and method for manufacturing same, and optical modulator

ActiveCN108885305AReduce lossesCheap and easy to manufactureOptical waveguide light guideNon-linear opticsRefractive indexEngineering

Provided are an optical element which can be inexpensively and easily manufactured and which is capable of adequately reducing or removing a higher mode while keeping loss of a fundamental mode low, amethod for manufacturing the same, and an optical modulator. The present invention has a substrate and first through third optical waveguides formed on the substrate and each having a lower claddinglayer, a core layer, and an upper cladding layer, the core layer having a larger refractive index than the lower cladding layer and the upper cladding layer, the first optical waveguide being optically connected to the second optical waveguide, the second optical waveguide being optically connected to the third optical waveguide, the first through third optical waveguides having a mesa structure in which top parts of at least the upper cladding layer and the core layer protrude on the lower cladding layer, the core height of the third optical waveguide being less than the core height of the first optical waveguide, the core height being the height to the top surface of the core layer from bottom surfaces on both sides of the mesa structure or locations where the inclination of lateral surfaces of the mesa structure becomes discontinuous approaching the bottom surfaces, and the mesa width of the third optical waveguide being less than the mesa width of the first optical waveguide, the mesa width being the width of the middle of the core layer.

Owner:FURUKAWA ELECTRIC CO LTD

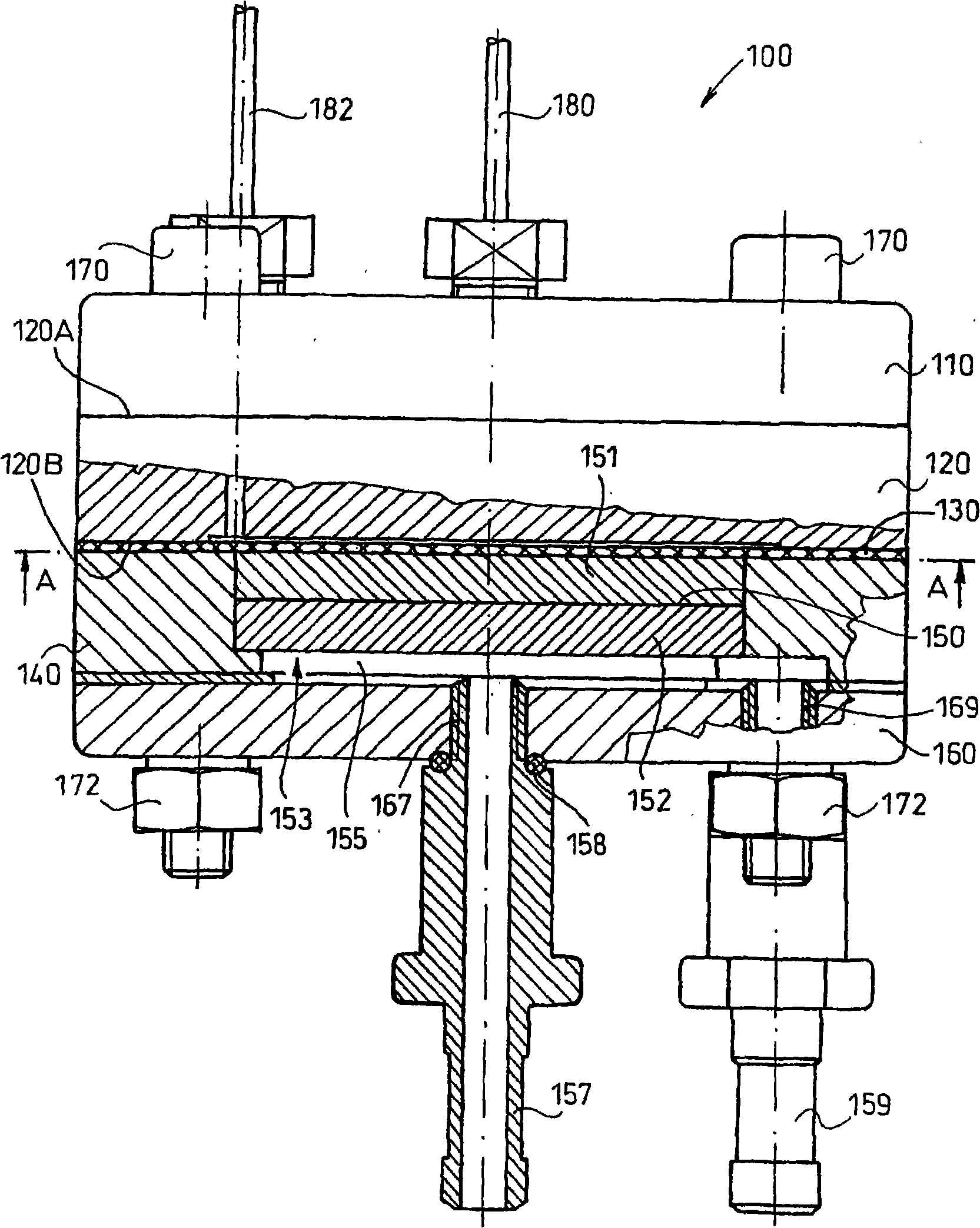

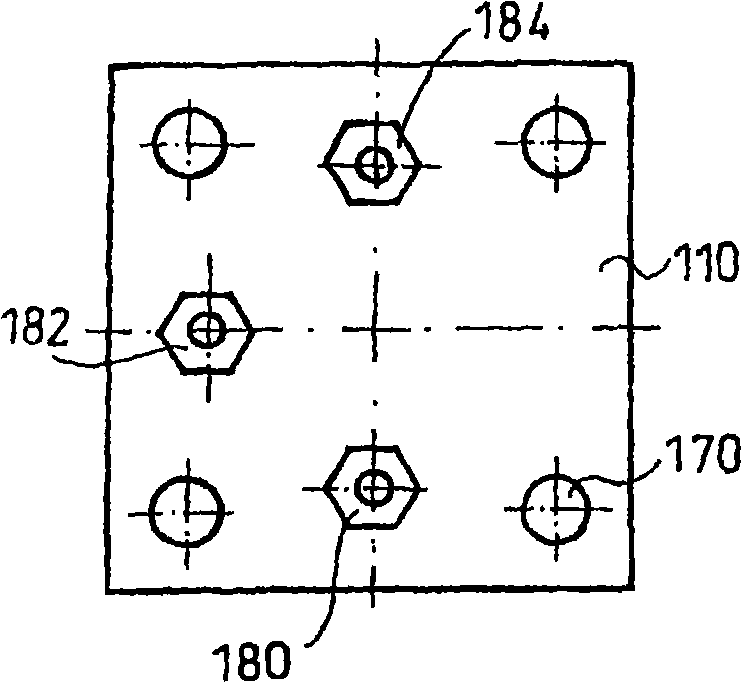

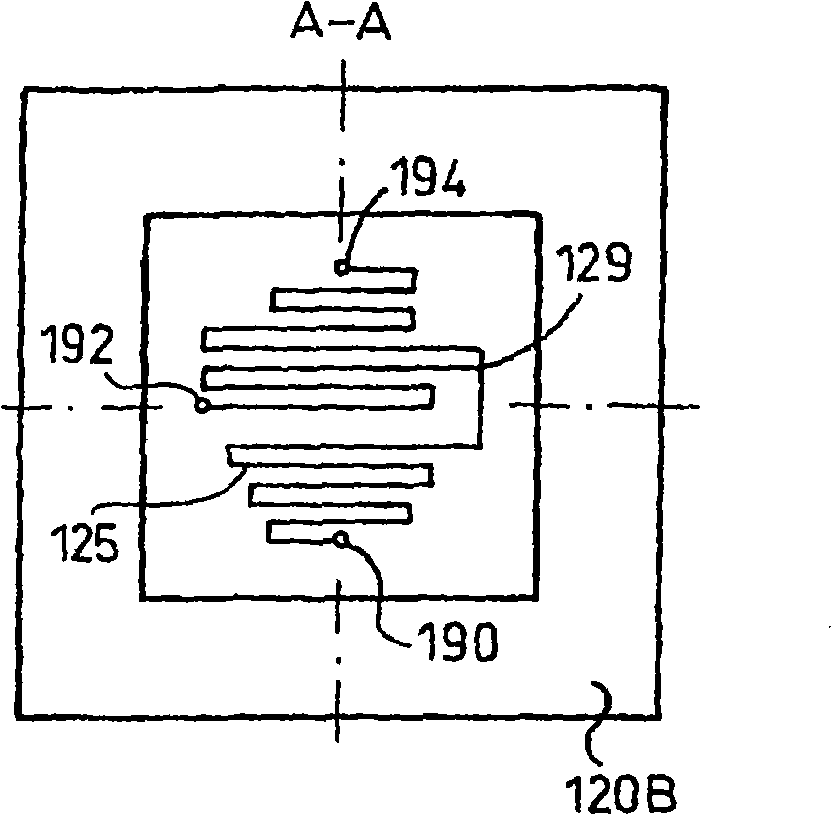

Method of forming a sealed channel of a microfluidic reactor and a microfluidic reactor comprising such channel

InactiveCN101360680AEliminate shortcomingsCheap and easy to manufactureDecorative surface effectsChemical vapor deposition coatingPlastic materialsEngineering

In a method according to the invention for forming a sealed channel (125) in the surface of a sheet made of a material with certain extent of plasticity, the machining surface of a tool with a rolling machining surface is brought into contact with a first point of the channel (125) to be formed in the surface of the sheet constituting a reactor block. Next, said machining surface is pressed onto the surface of the sheet with a compressive force (F) required to achieve the depth of the channel (125) to be formed, whereby the plastic material is squeezed out and becomes raised from the sheet surface on the peripheries of the depression being formed. After this, while maintaining the compressive force (F), by displacing said machining surface along the centerline of the channel (125) over the sheet surface it is rolled from the first point of the channel (125) to be formed to a second point thereof, whereby the channel (125) is machined in the material of the sheet and sealing edges (127) are created on the peripheries of the channel (125) from the material squeezed out and become raised. After creating said sealing edges (127), a closing member bearing against the sealing edges (127) is arranged at the surface of the sheet provided with the channel (125) and the sealing edges (127), and then said closing member is pressed onto the sheet by a compressive force required to deform said sealing edges (127) and is fixed in the position obtained, whereby a sealed channel (125) running between the first and second points is formed within the reactor block.

Owner:THALES NANOTECHNOLOGIAI RT (HU)

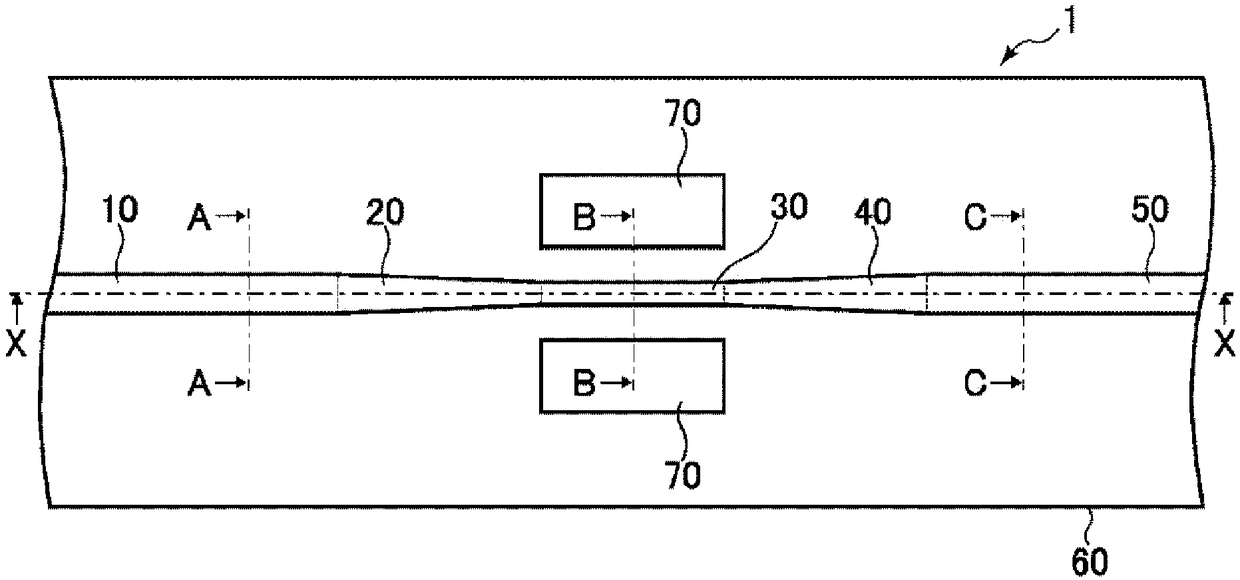

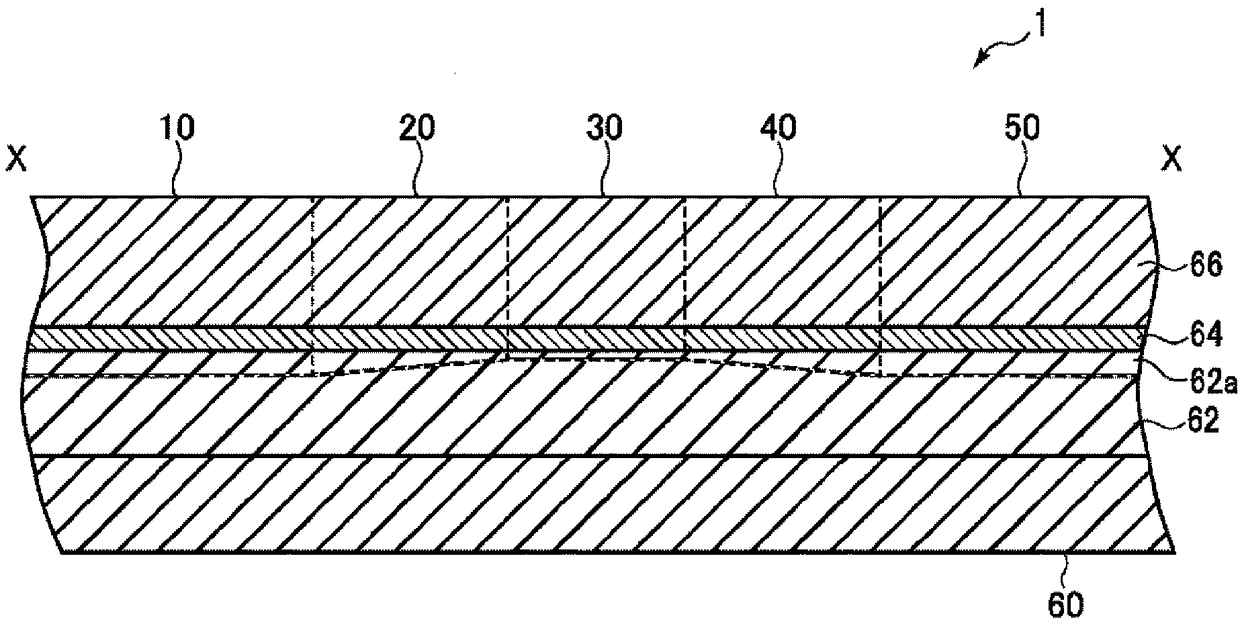

Optical film, multilayer optical film including same, and method for producing optical film

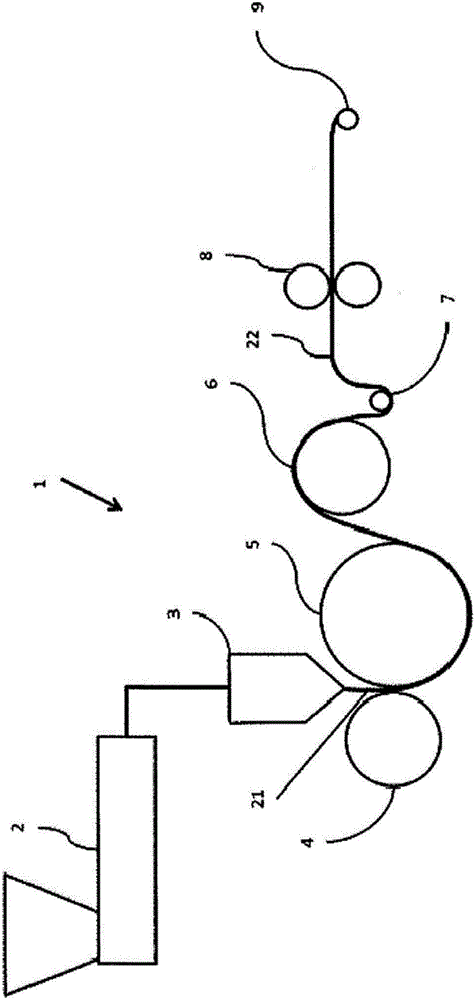

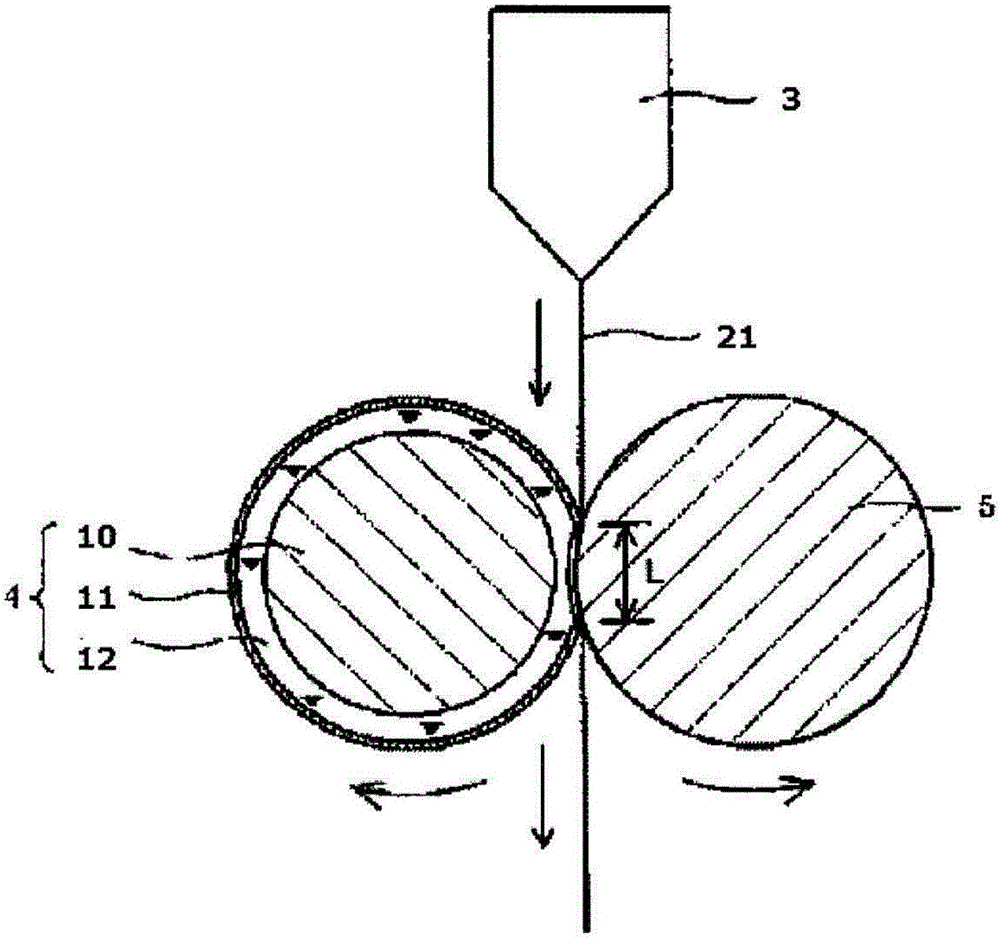

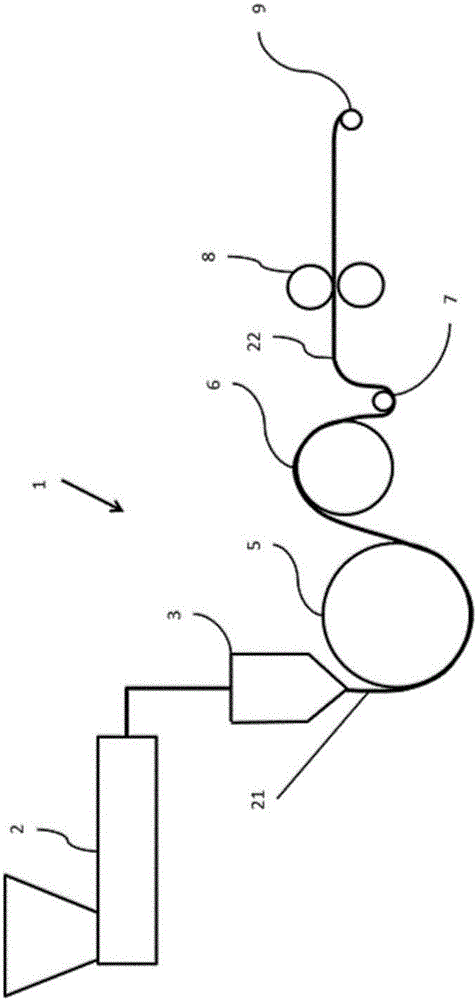

ActiveCN106662693ACheap and easy to manufactureCompensation angle of viewSynthetic resin layered productsPolarising elementsChemistryOptical film

Provided are: an optical film that has a good appearance, low in-plane retardation Re, and high thickness-direction retardation Rth; and a method for producing such an optical film. Also provided is a multilayer optical film that uses the optical film, that exhibits little change in retardation as a result of wavelength, and that has small retardation at low wavelengths. The optical film is obtained by sandwiching a melted resin between a first cooling roll comprising an elastic metal roll and a second cooling roll comprising a non-elastic metal roll and molding said melted resin. The optical film has a good appearance, the absolute value of the in-plane retardation Re thereof is 10 nm or less, and the thickness-direction retardation Rth thereof is 40 nm or more.

Owner:MITSUBISHI GAS CHEM CO INC +1

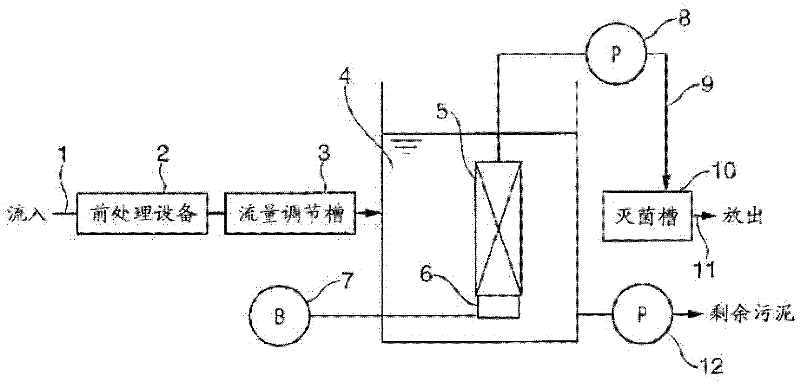

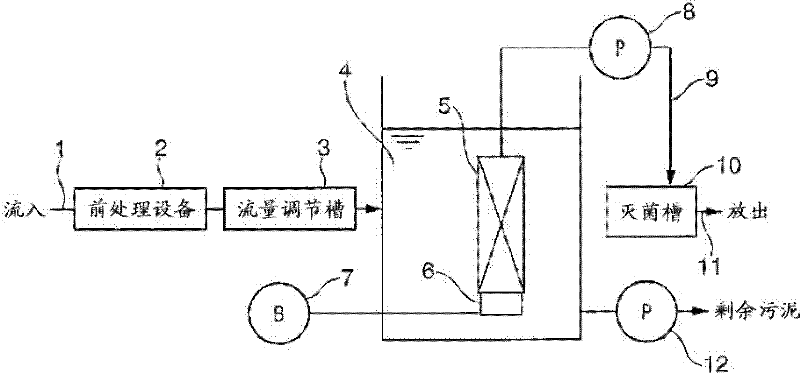

Additive used in a membrane-separation activated sludge process

InactiveCN102548914AStabilizationCheap and easy to manufactureBioreactor/fermenter combinationsFungiActivated sludgePolysaccharide

In order to provide a means that can process organic wastewater via a membrane-separation activated sludge process that is stable over a long period of time, by reducing the quantity of biological polymers that can cause permeability problems, an additive is provided that is added to the activated sludge when treating organic wastewater via a membrane-separation activated sludge process. Said additive contains microorganisms that decompose polysaccharides.

Owner:ASAHI KASEI CHEM CORP +1

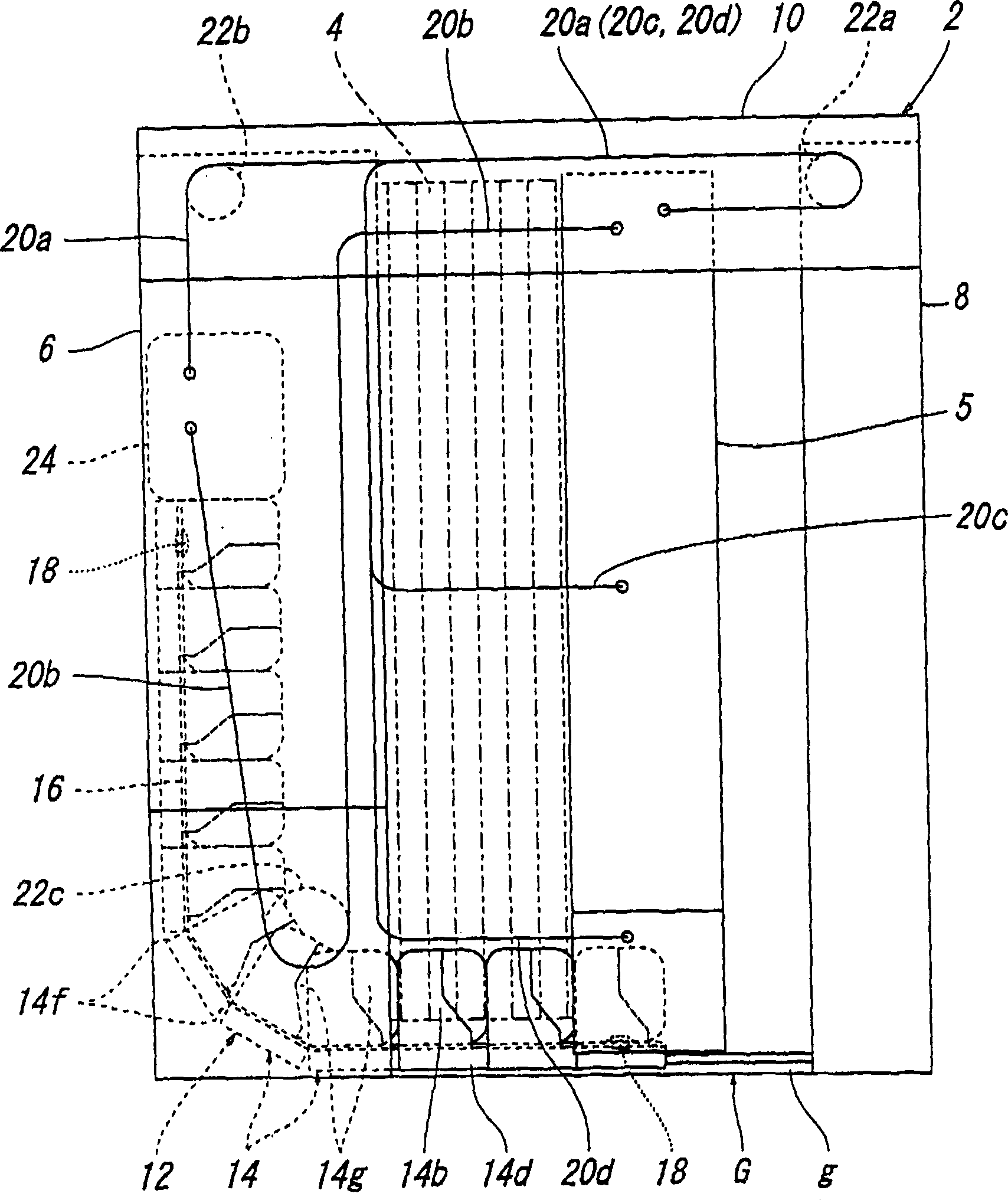

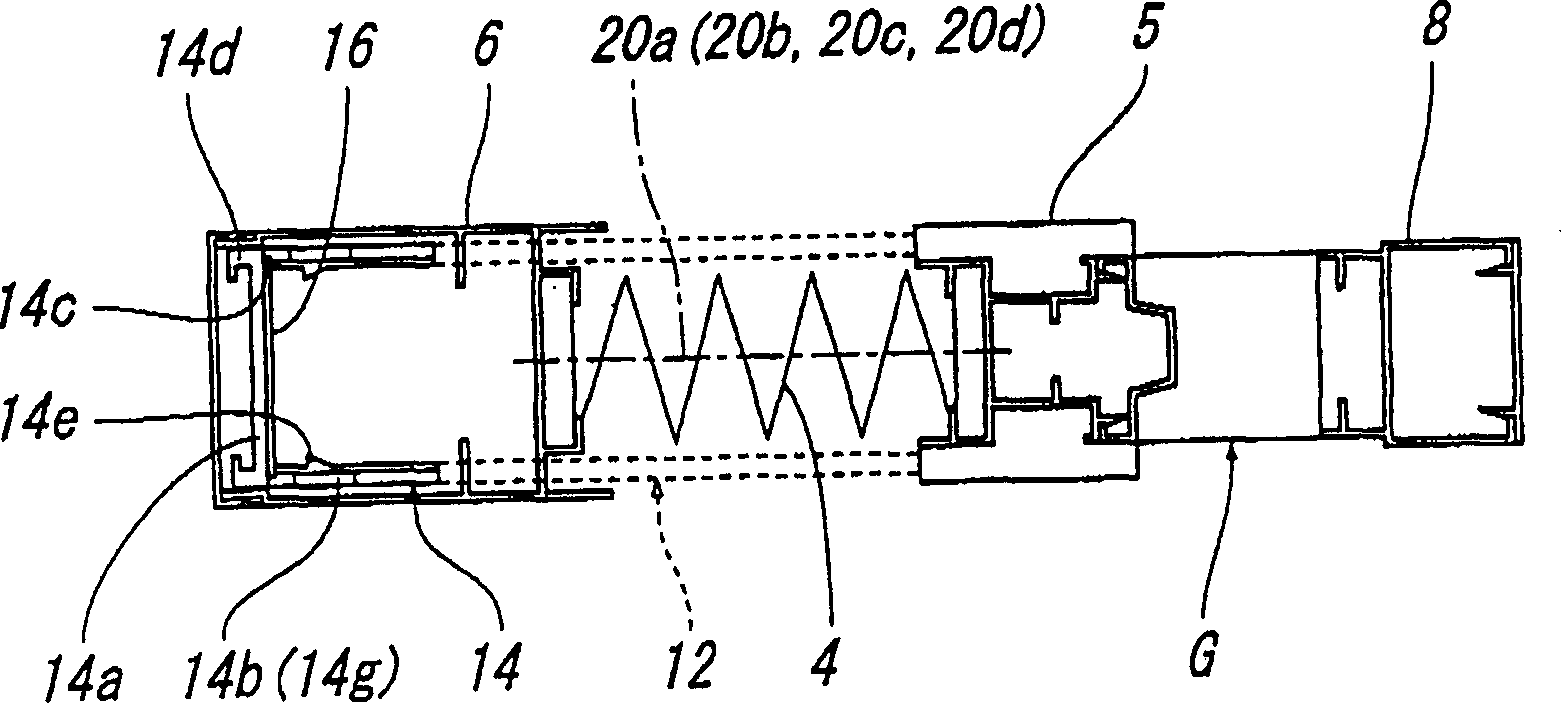

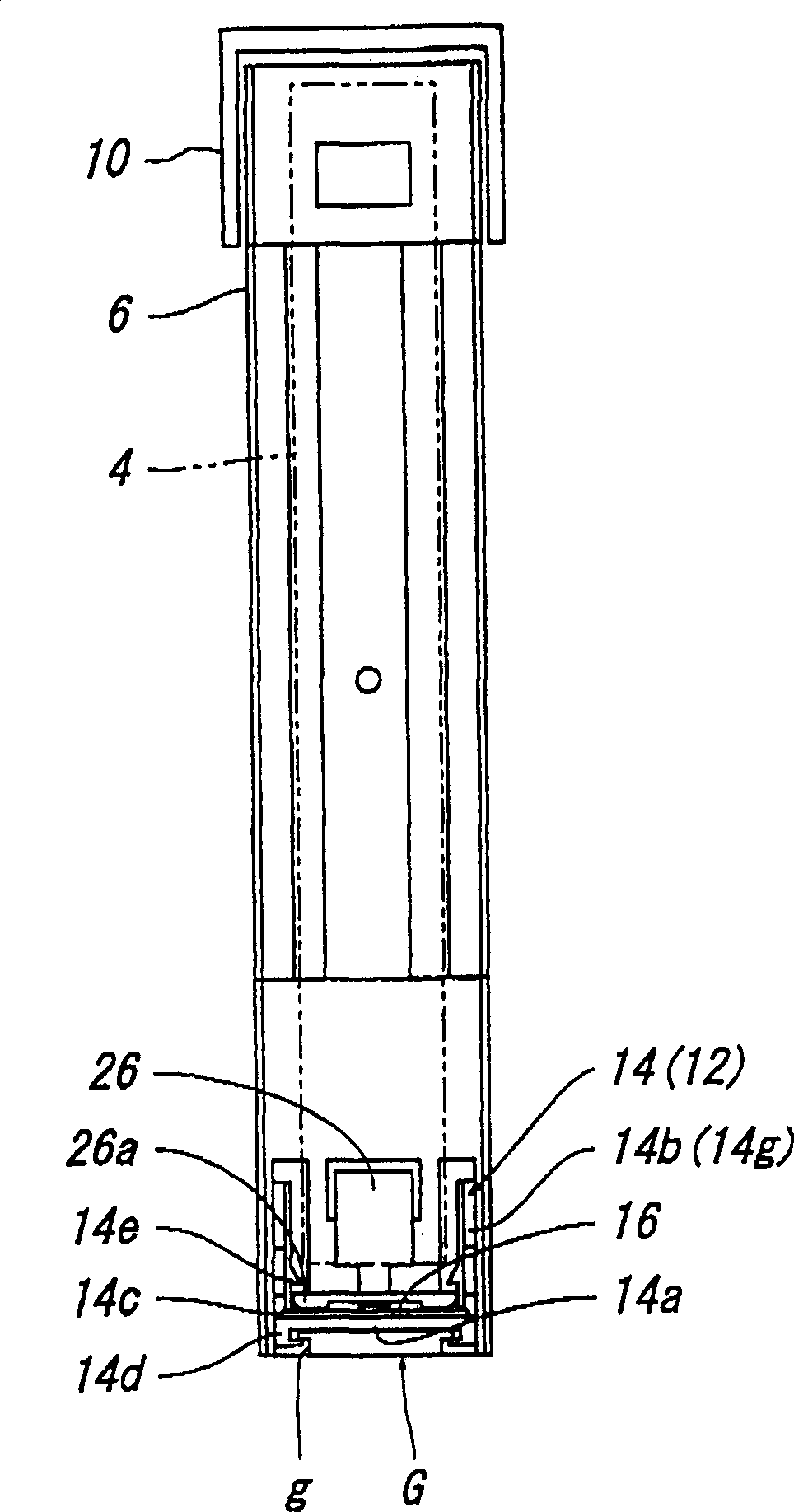

Sliding screen door

InactiveCN1268830CBend stopAvoid liftingExtensible doors/windowsInsect protectionEngineeringElectrical impedance

The invention provides a sliding screen door having a net guide that moves in association with the opening and closing movement of a net, wherein the opening and closing operation of the screen door can be performed smoothly while providing a buffering effect with an adequate resistance, without hindering the opening and closing operability of a movable edge member, by enabling a reaction force, which is required for its bending, to be used as a buffering force against the operating force of the movable edge member, the net guide being formed by connecting guide pieces. In order to do so, a net guide 12 fed out from and drawn into the lower end of the vertical frame member 6 in association with the opening and closing operation of the net 4, is provided for guiding the lower end of the net 4. The net guide 12 is formed by connecting with a tape member 16 a number of guide pieces 14 formed substantially into a U-shape with a bottom portion 14a and a stabilizing portion 14b. The tape member 16 is inserted into the insertion devices 14c on the guide pieces 14 and the guide pieces 14 at both ends are fixed to the tape member 16.

Owner:SEIKI JUKO

Fork for clutch and manufacturing method thereof

InactiveCN104032210ACheap and easy to manufactureFull strengthMechanical actuated clutchesFurnace typesClutchGraphite

A fork for a clutch and a manufacturing method thereof are provided. The fork for a clutch may include C: 3.4˜3.9%, Si: 2.1˜2.5%, Mn: 0.2˜0.7%, P: 0.01% or less, S: 0.009˜0.02%, Cu: 0.2˜0.4%, and Mg: 0.04˜0.07% by weight ratio, with the remainder including iron (Fe) and other impurities. The material forming the fork for the clutch may have a structure in which spheroidal graphite is precipitated in an austenite matrix structure.

Owner:LG ELECTRONICS INC

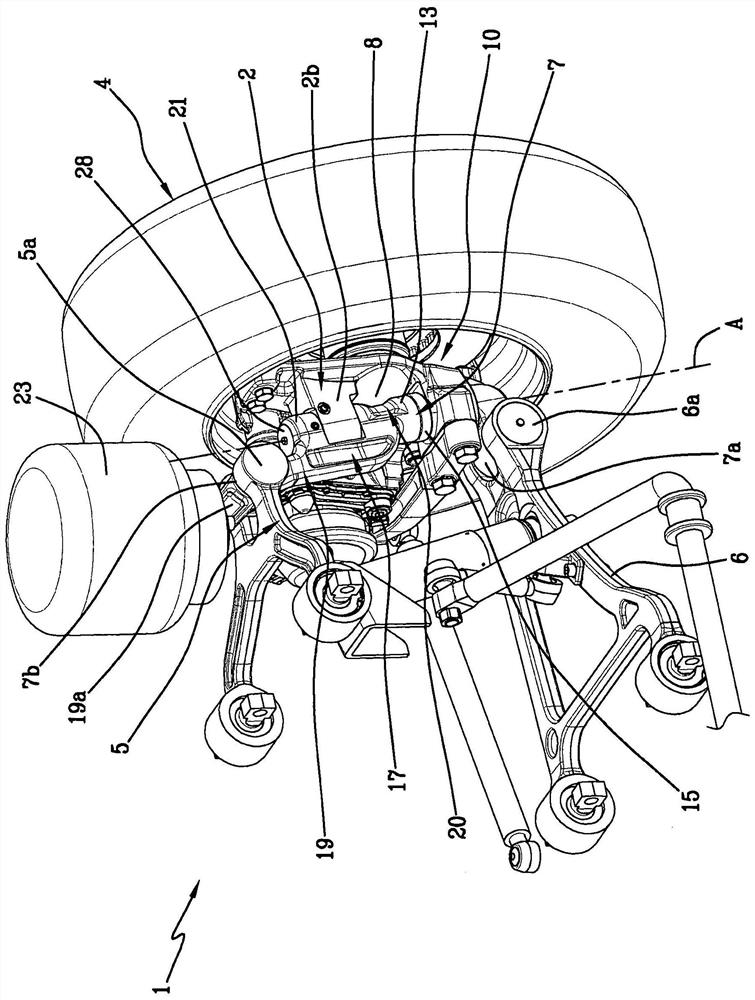

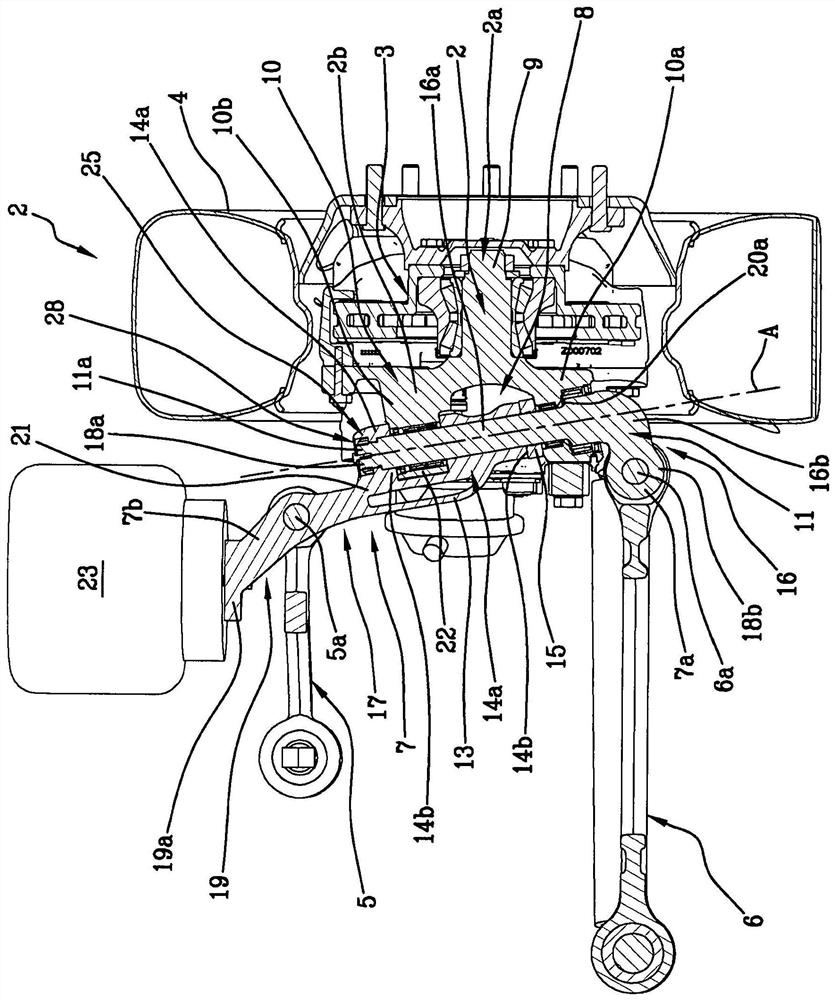

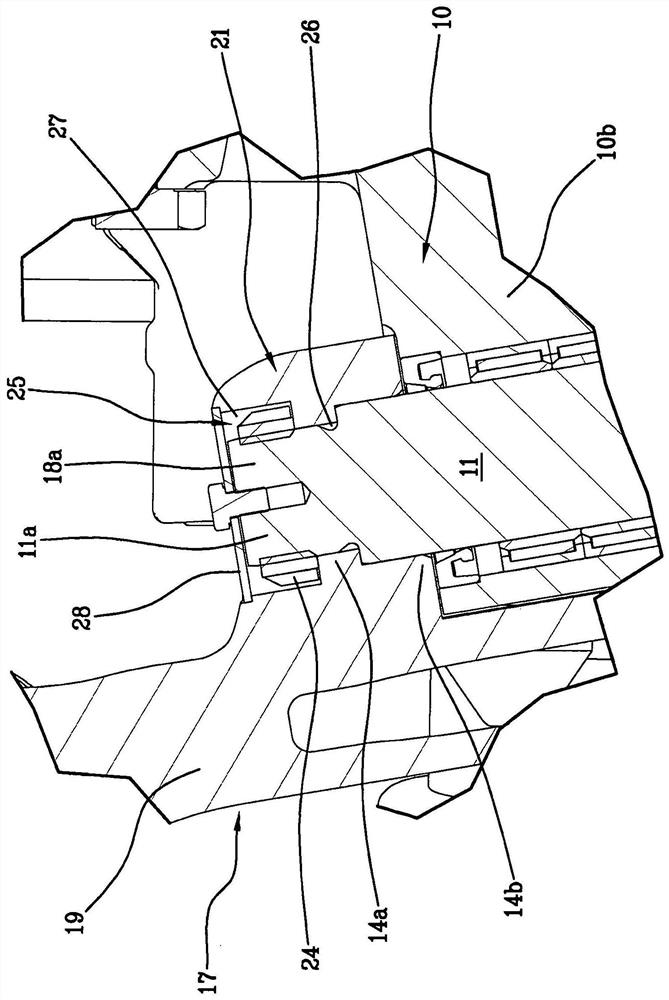

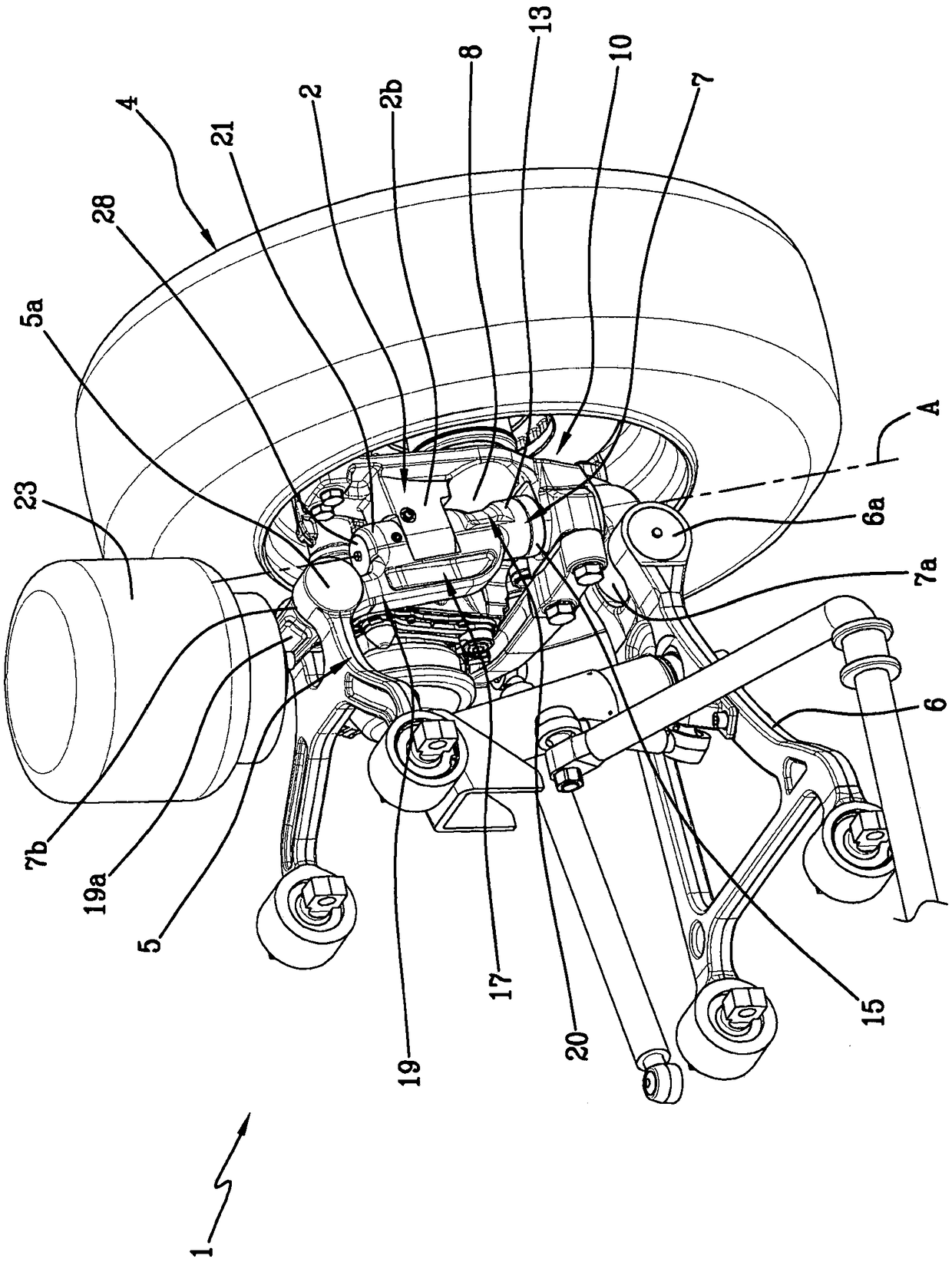

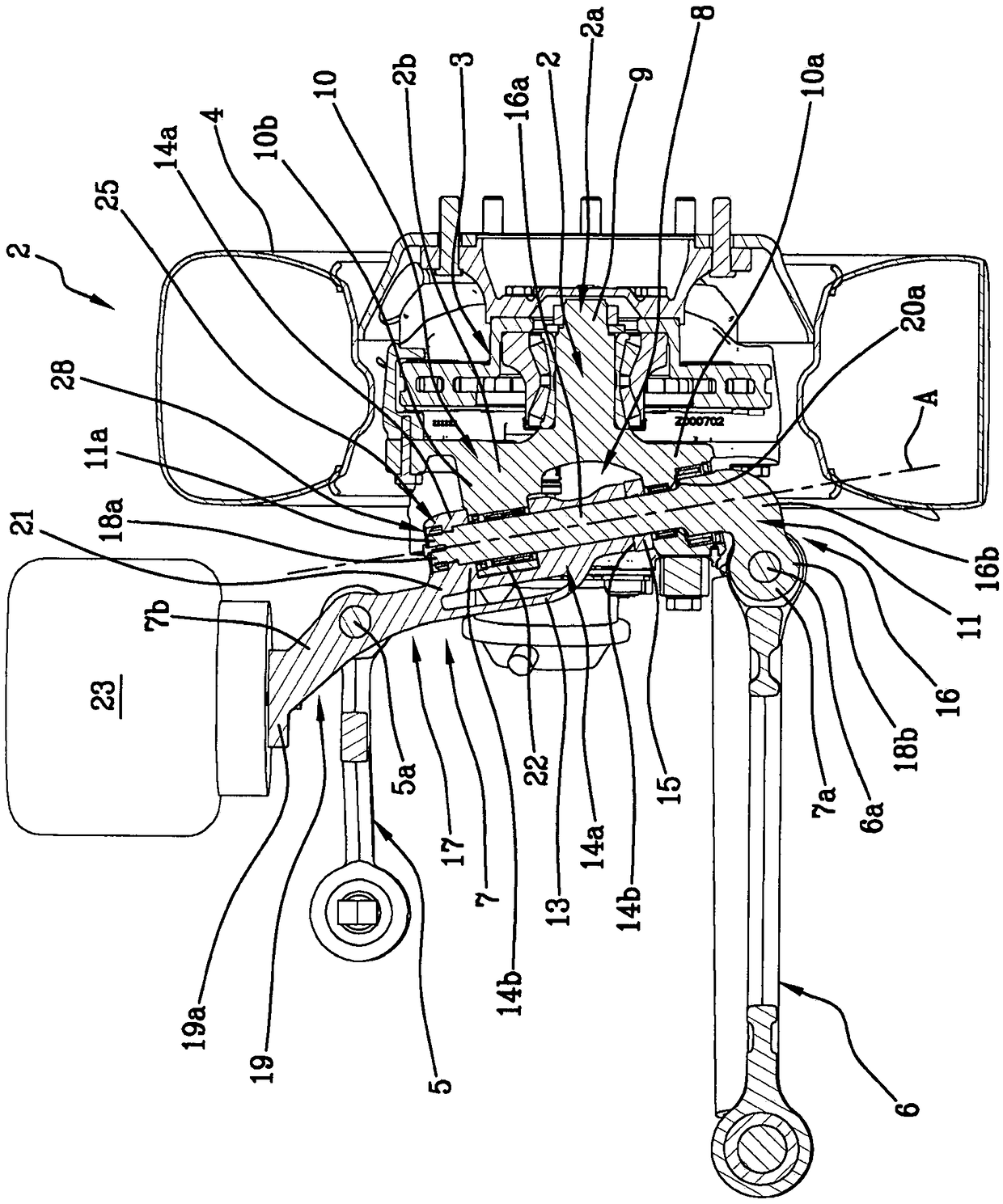

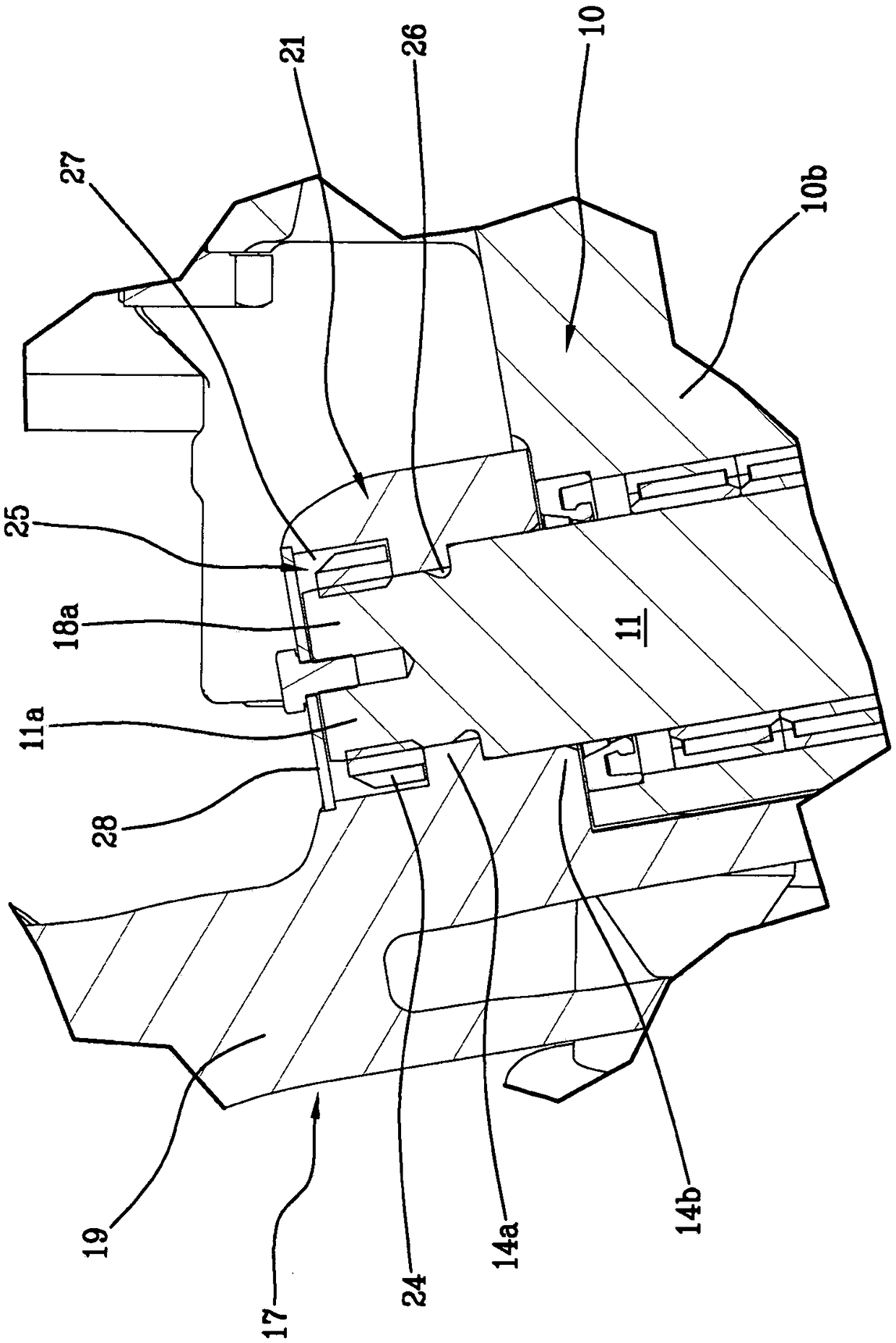

Independent suspensions for vehicles, especially suspensions for steering wheels of vehicles

ActiveCN109153411BFinite ground arm valueEasy to assembleSteering linkagesResilient suspensionsRotational axisControl theory

Independent suspension for vehicles, especially for heavy vehicles, comprising: a steering knuckle (2) extending between an outer part (2a) defining the axis of rotation of the hub and an inner part (2b), the inner part Has a receptacle extending transversely to said outer portion along the steering axis (A), and a steering knuckle bracket (7) assembly is rotatably coupled to the inner portion of the steering knuckle (2) to allow steering around said steering Relative rotation of axis (A) and included on steering axis (A). At least the first (7a) and second support parts (7b) define each substantially horizontal hinge point (5a, 6a) for one end of the respective transverse arm (5, 6). The steering knuckle bracket assembly (7) includes a first body (16) and a second body (17) spaced apart from each other, wherein the first body (16) includes a steering pin (11) extending along the steering axis (A). The first support portion (7a) and the second body (17) are partially fitted around the steering pin (11) and include a second support portion (7b).

Owner:BRIST AXLE SYST

Independent suspension for vehicles, in particular suspension for directional wheel for vehicles

ActiveCN109153411AEasy to assembleSimple mold makingSteering linkagesResilient suspensionsKnuckleEngineering

An independent suspension for vehicles, in particular for heavy vehicles, comprises a steering knuckle (2) developing between an outer portion (2a), defining the axis of rotation of a wheel hub, and an inner portion (2b), having a receiving seat extending transversely to the outer portion along a steering axis (A) and a knuckle-carrier (7) assembly rotatably coupled to the inner portion of the knuckle (2) to allow a relative rotation around the steering axis (A), and comprising at least a first (7a) and a second supporting portion (7b) defining each a substantially horizontal hinge point (5a,6a) for one end of a respective cross arm (5, 6). The knuckle-carrier assembly (7) comprises a first (16) and a second body (17), separate to each other, in which the first body (16) comprises a steering pin (11) developing along the steering axis (A) and the first supporting portion (7a), and the second body (17) is partially fitted around the steering pin (11) and comprises the second supportingportion (7b).

Owner:BRIST AXLE SYST

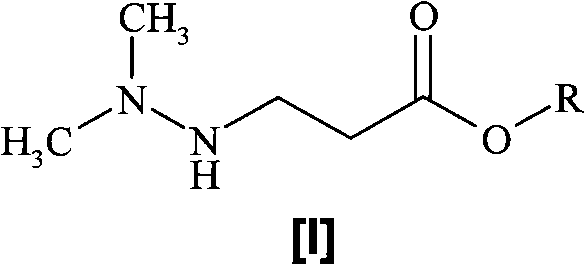

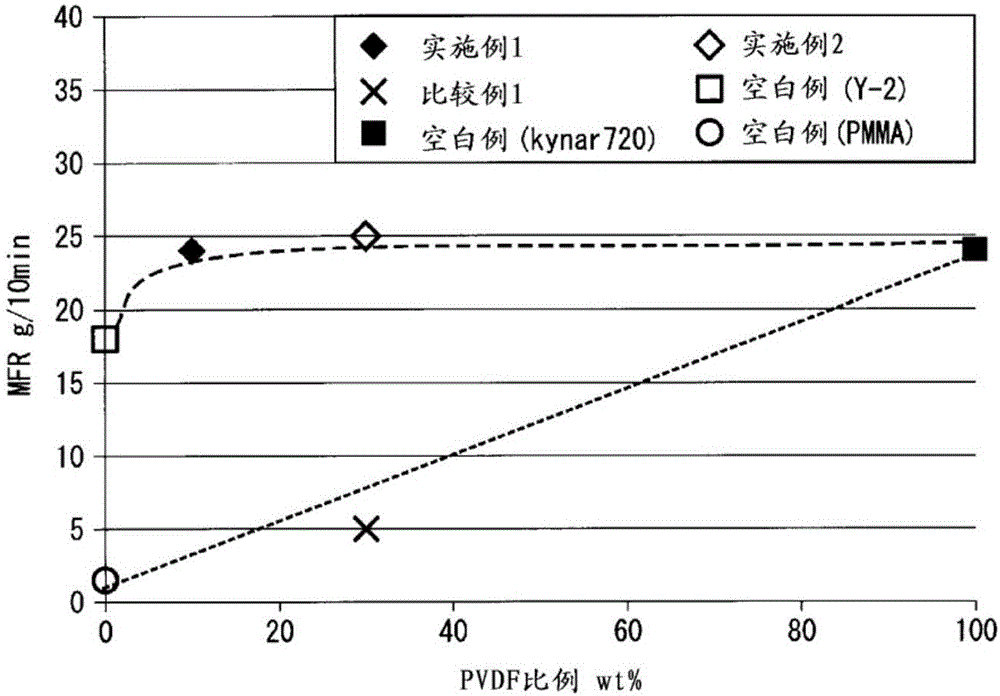

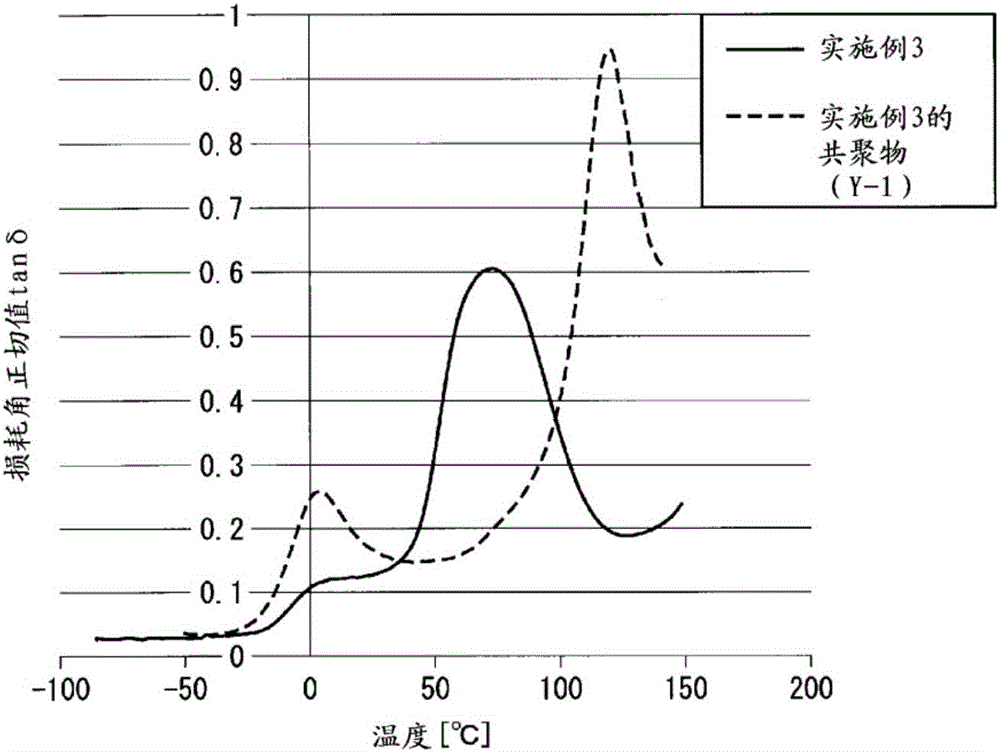

Resin composition and molded body formed from resin composition

A resin composition which contains from 5% by mass to 65% by mass (inclusive) of a polymer (X) described below and from 35% by mass to 95% by mass (inclusive) of a polymer (Y) described below. Alternatively, a resin composition which contains more than 65% by mass but 85% by mass or less of a polymer (X) described below and 15% by mass or more but less than 35% by mass of a polymer (Y) described below, wherein a domain (y1) described below or a domain (y2) described below contains a macromonomer unit. Polymer (X): a vinylidene fluoride resin Polymer (Y): a copolymer having a domain (y1) that is compatible with the polymer (X) and a domain (y2) that is incompatible with the polymer (X)

Owner:MITSUBISHI CHEM CORP

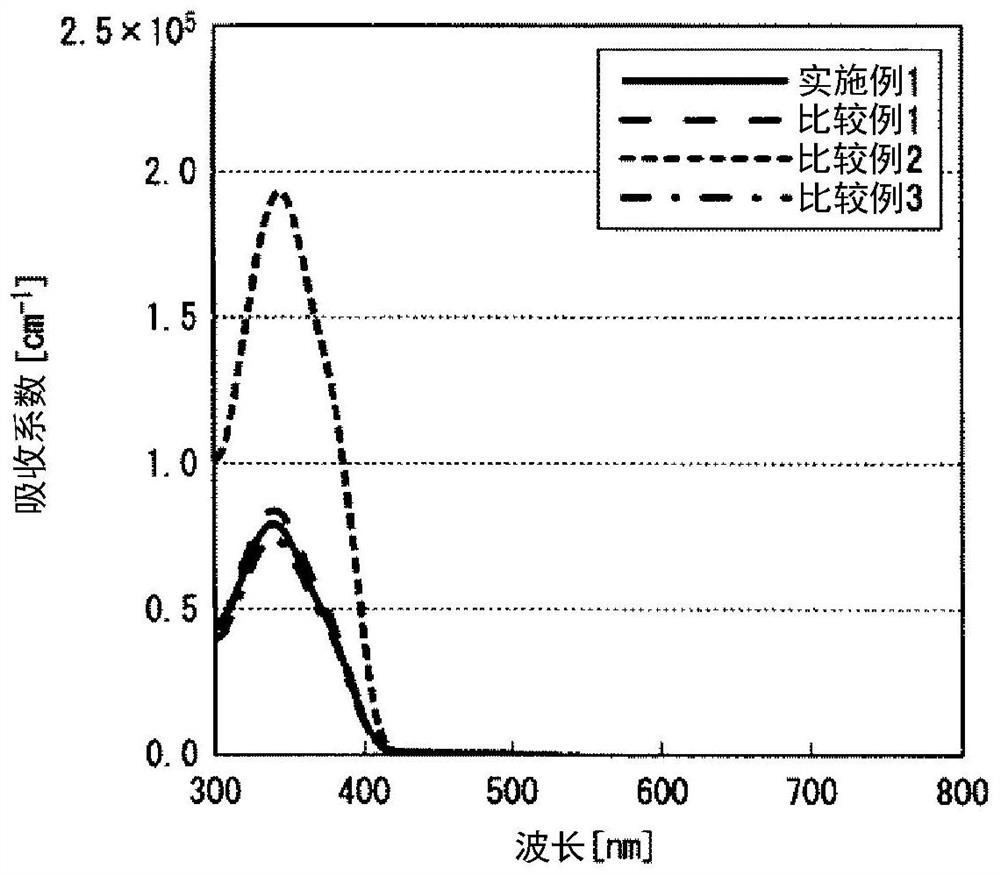

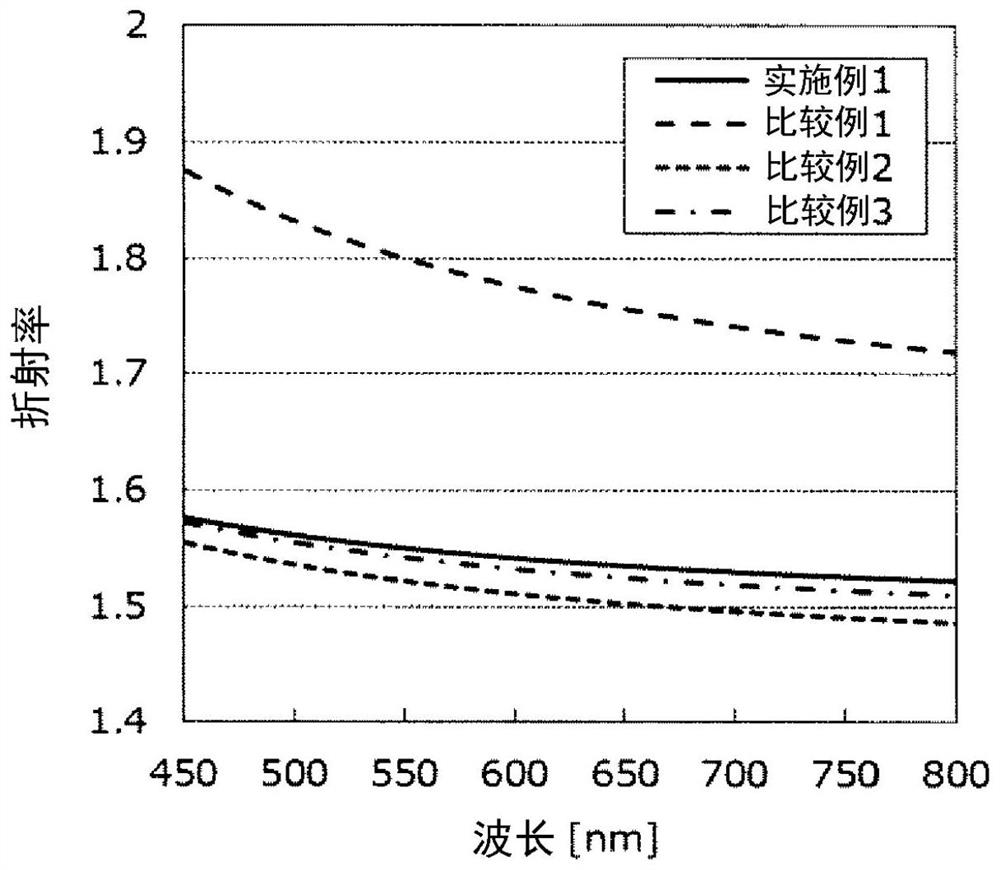

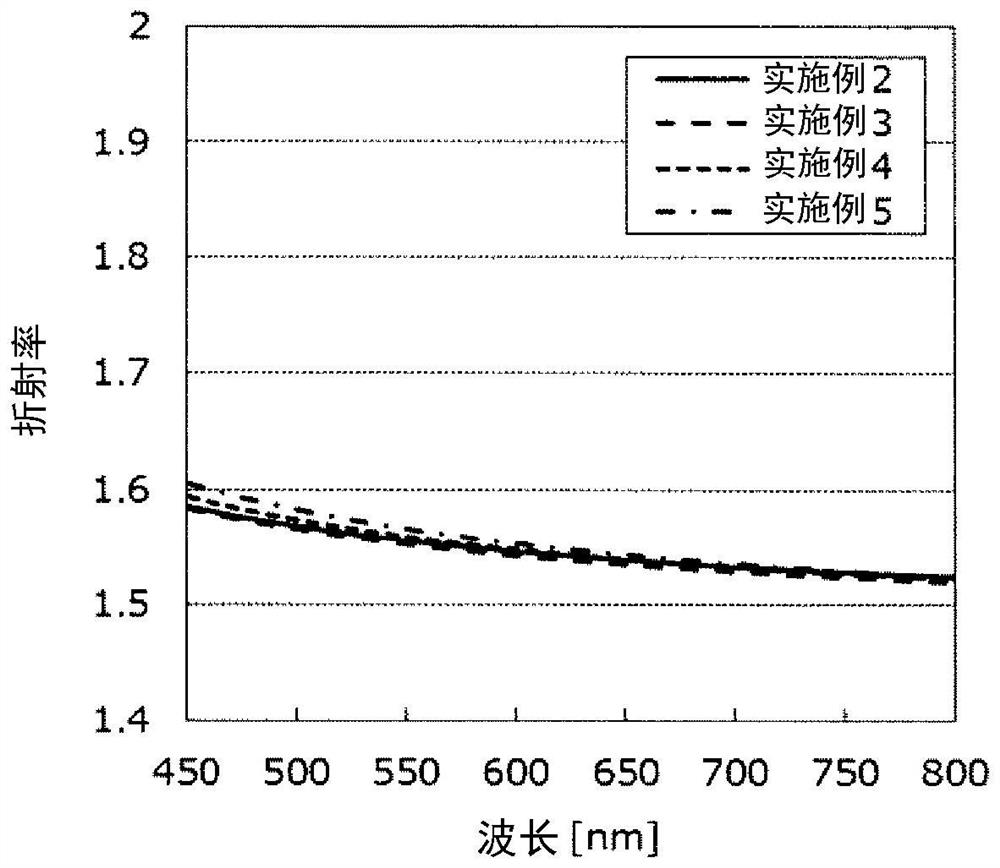

Composition and organic optoelectronic element and its manufacturing method

ActiveCN110088928BImprove light extraction efficiencyCheap and easy to manufactureElectroluminescent light sourcesSolid-state devicesRefractive indexPhysical chemistry

Owner:YAMAGATA UNIVERSITY +1

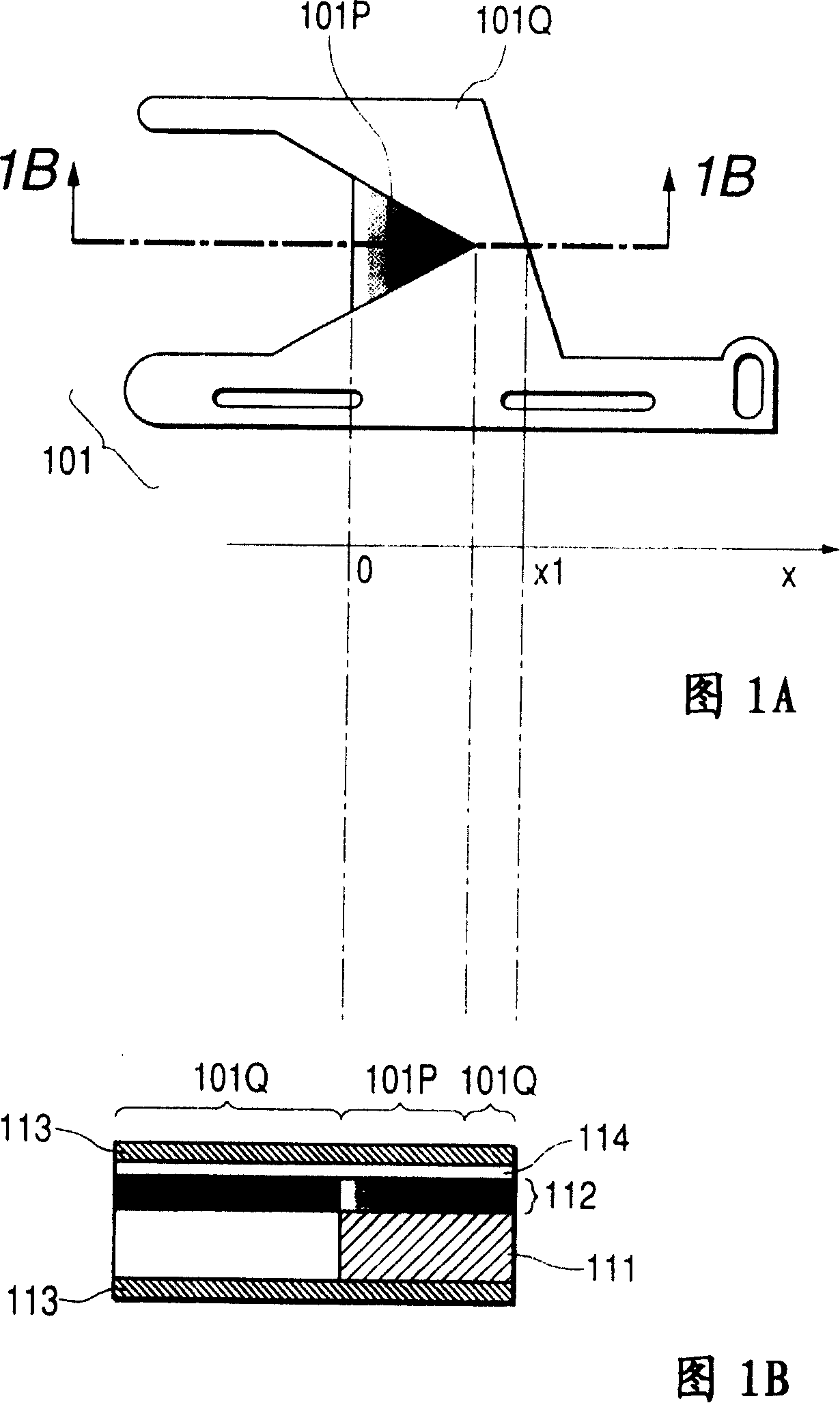

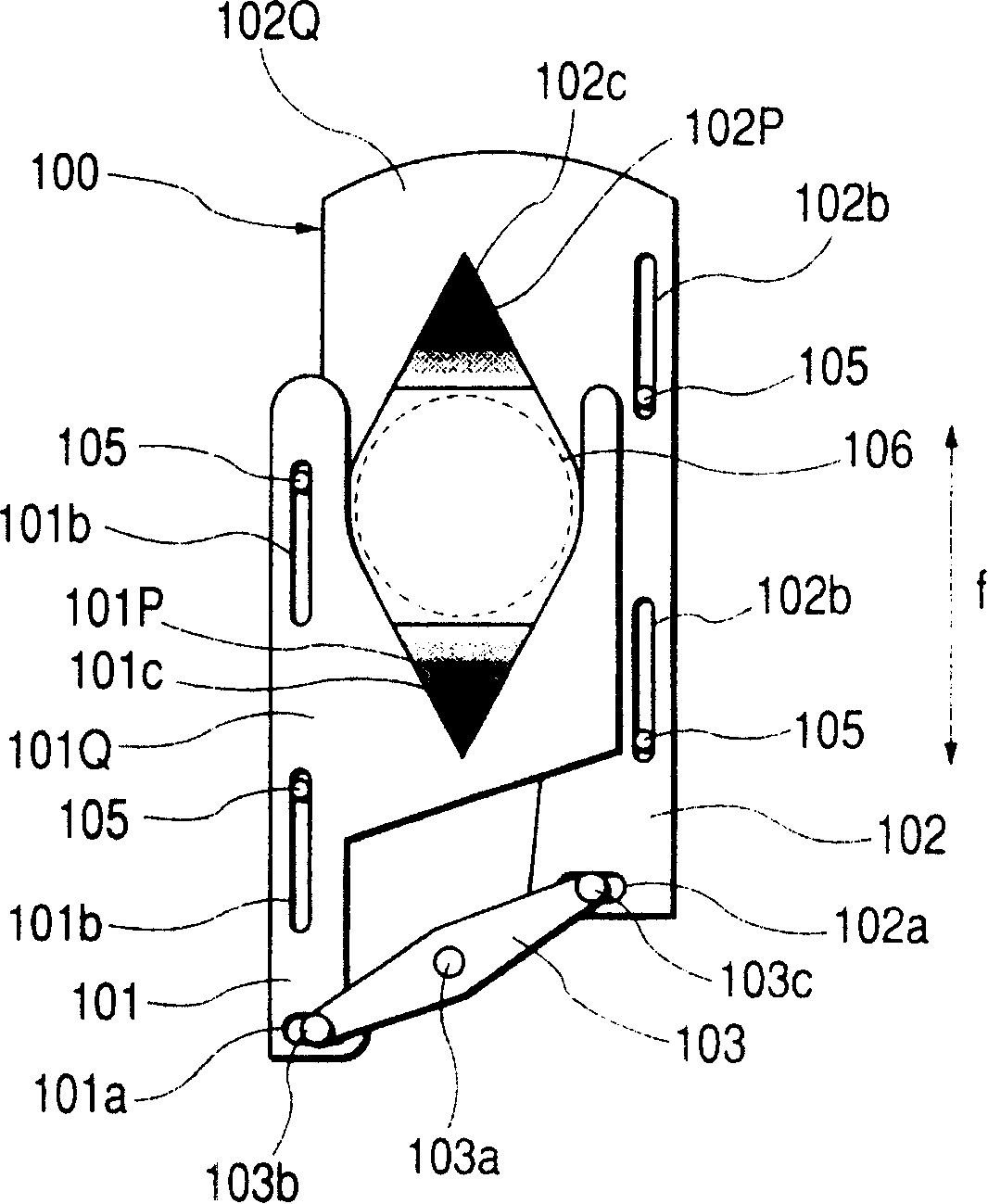

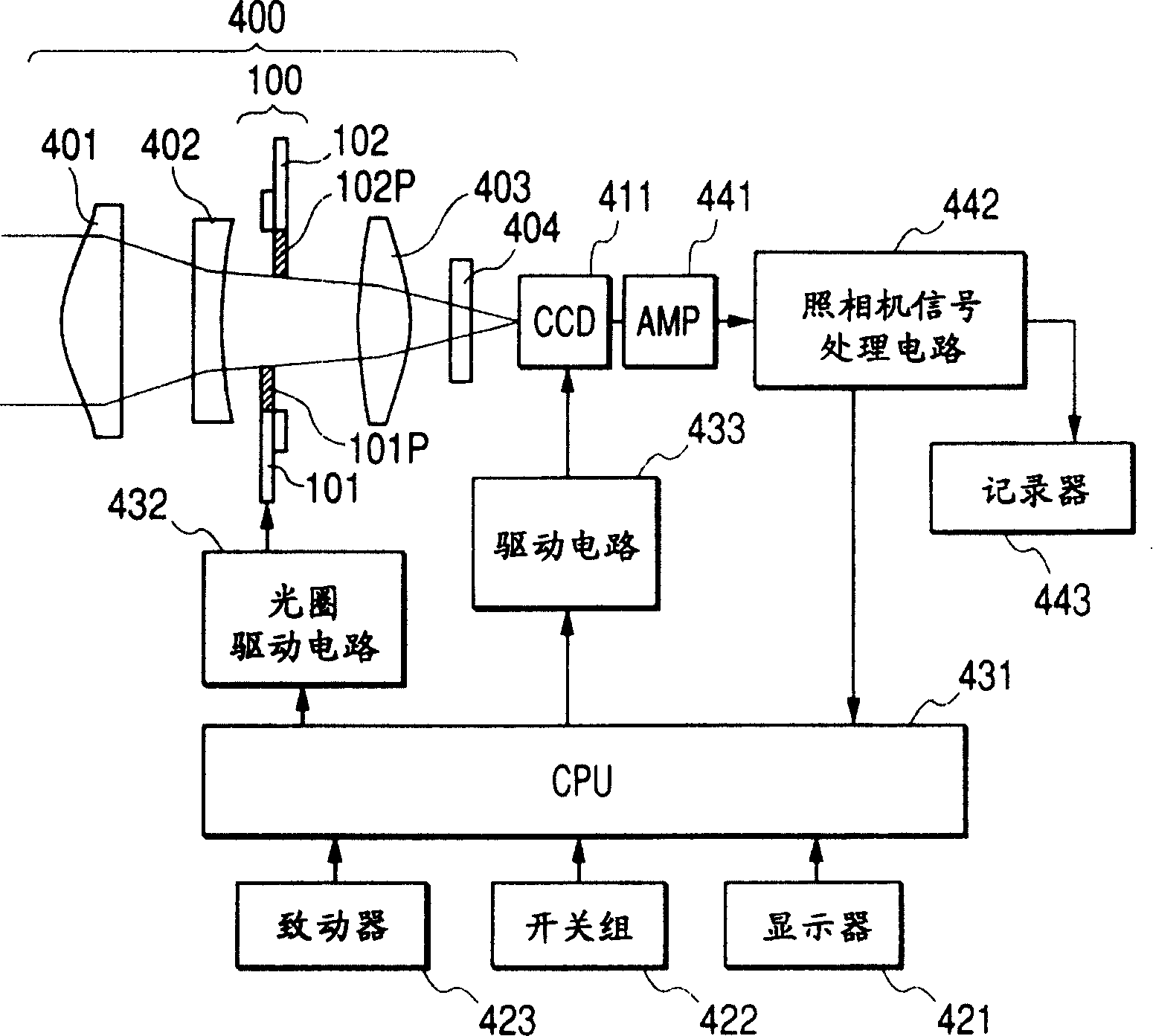

Light quantity regulating device, its manufacture method, and photographic device

InactiveCN100390573CReduce manufacturing costFully satisfy the optical characteristicsOptical filtersPattern printingLiquid jetOptical property

A production process of a light amount adjustment member, by which a light amount adjustment member that can sufficiently satisfy optical properties can be economically produced at low production cost and high yield by a simple operation is provided. In addition, a wide variety of light amount adjustment devices and photographing apparatus equipped with a light amount adjustment member are cheaply provided while achieving satisfactory optical properties. The production process of the light amount adjustment member comprises the step of applying a coloring liquid containing a coloring material to a transparent base material using a liquid jet recording process to form a light amount adjustment region having a particular optical density.

Owner:CANON KK

High efficiency back surface electrode-type solar cell and manufacturing method therefor

ActiveCN110800114AImprove photoelectric conversion efficiencyGood electrical contactFinal product manufacturePhotovoltaic energy generationElectrical conductorElectrical battery

The present invention is a rear-surface-electrode-type solar cell in which a first main surface of a crystalline silicon substrate has a p-type region that has p-type electrical conductivity, and an n-type region that has n-type electrical conductivity, the rear-surface-electrode-type solar cell comprising a positive electrode that is formed on the p-type region and a negative electrode that is formed on the n-type region, wherein the solar cell is characterized in that: the positive electrode comprises a laminated electrical conductor made from a first electrical conductor that is formed on the p-type region and contains a group III element, and a second electrical conductor that is laminated on the first electrical conductor, the group III element content being less than that of the first electrical conductor; and the negative electrode comprises a second electrical conductor that is formed on the n-type region. Thereby provided is an inexpensive rear surface electrode-type solar cell that has high photoelectric conversion efficiency.

Owner:SHIN ETSU CHEM IND CO LTD

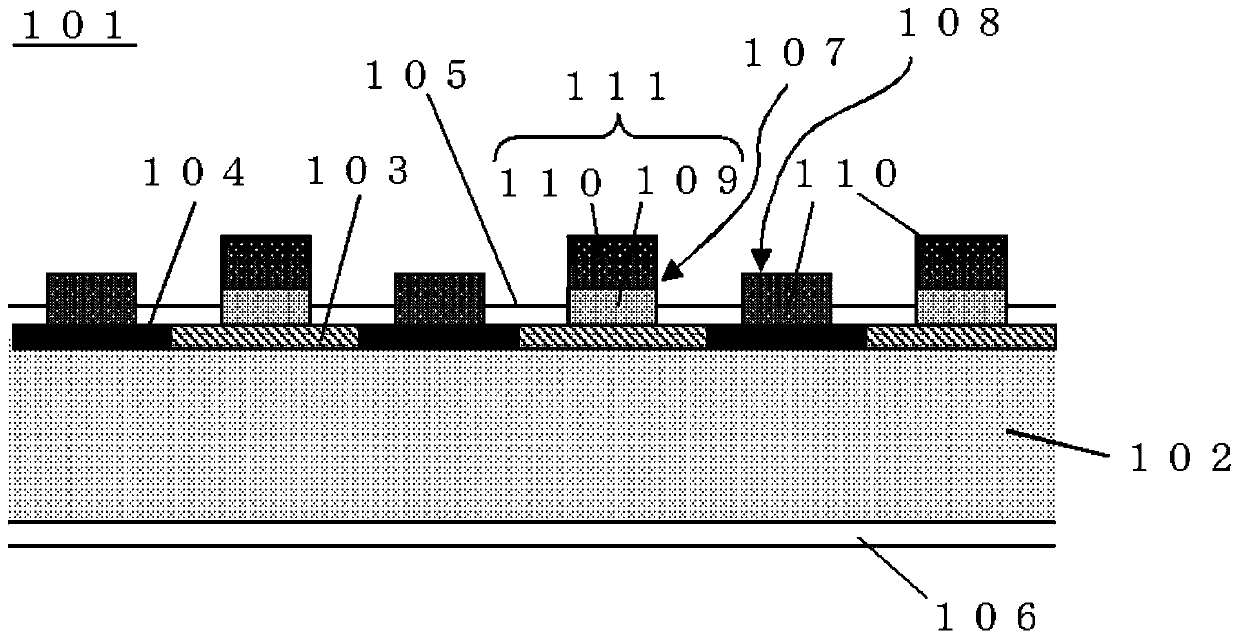

Light source device

ActiveCN100570808CCheap and easy to manufactureEasy to manufactureCoupling device connectionsElectric discharge tubesPunch pressEngineering

The present invention is designed to make the base-structure easy to manufacture the lamp-base and base-holder in order to attach the light-source apparatus precisely with checking the adaptability of the discharge lamp. The concaves 14, 34 of mirror symmetry with each other are formed in the base structure 1 and the base holder 3. The concaves 14, 34 can be formed precisely with laser working etc. An electro-conductive plate with thickness equal to the sum of the depth of concaves 14, 34 is punched by a press machine to make a piece 2 fit for the concaves 14, 34 and it is infixed to the second concave 34. The base structure 1 is inserted to the base holder 3 and then the piece 2 infixed in the second concave 34 of the base holder 3 fits to the first concave 14 of the base structure. The piece 2 enables the base structure 1 to align with the base holder 3 and then the both can be attached easily and precisely.

Owner:ORC MFG

PRECIPITATION HARDENING-TYPE Ag-Pd-Cu-In-B-BASED ALLOY

ActiveCN111511939ALow resistivityImprove reliabilityElectrical measurement instrument detailsElectrical testingElectrical resistance and conductanceHardness

Owner:TOKURIKI HONTEN

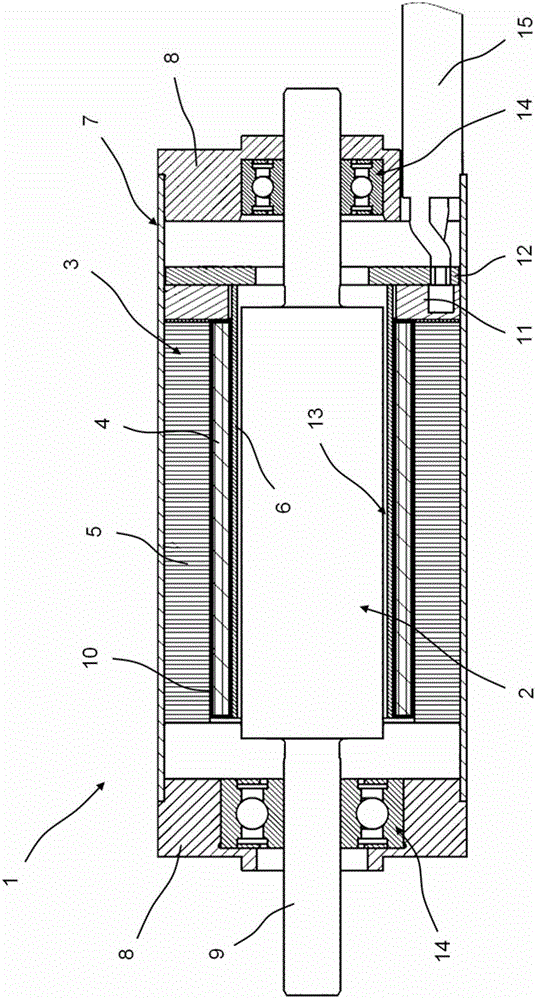

Electric Motors for High Temperature Applications

ActiveCN103138427BFast preparationCheap and easy to manufactureWindings insulation materialMagnetic circuit stationary partsEngineeringZirconium oxide

The electric motor (1) has a rotor (2) and a stator (3) with a hollow-cylindrical, ironless stator winding (4) which is wound from a stoved-enamel wire. The hollow-cylindrically designed stator winding is enclosed by a hollow-cylindrical soft-magnetic return. The stator winding is supported by a hollow-cylindrical supporting sleeve which is laid radially inside against the stator winding. The sleeve is made of ceramic or zirconium oxide.

Owner:MAXON MOTOR AG

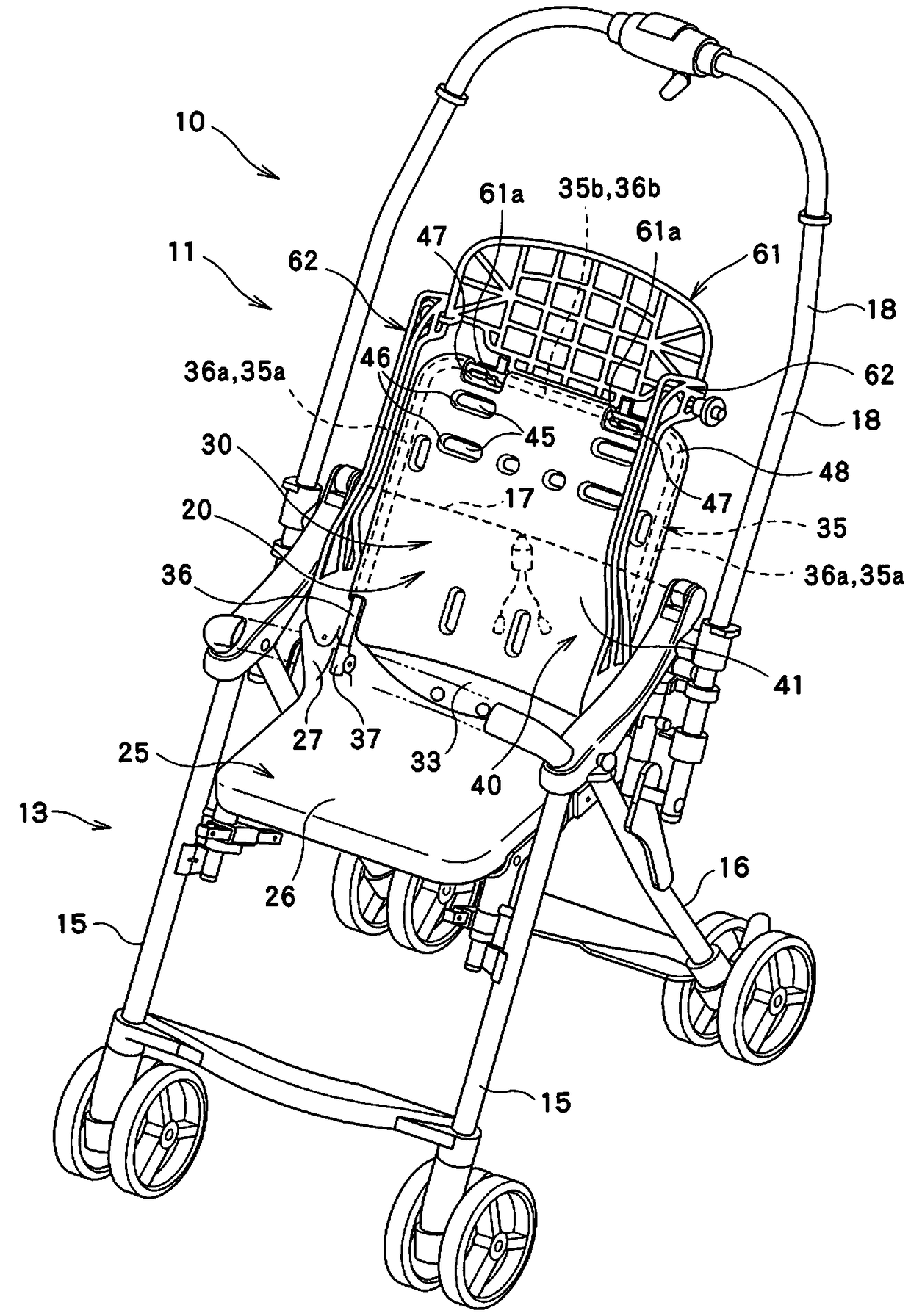

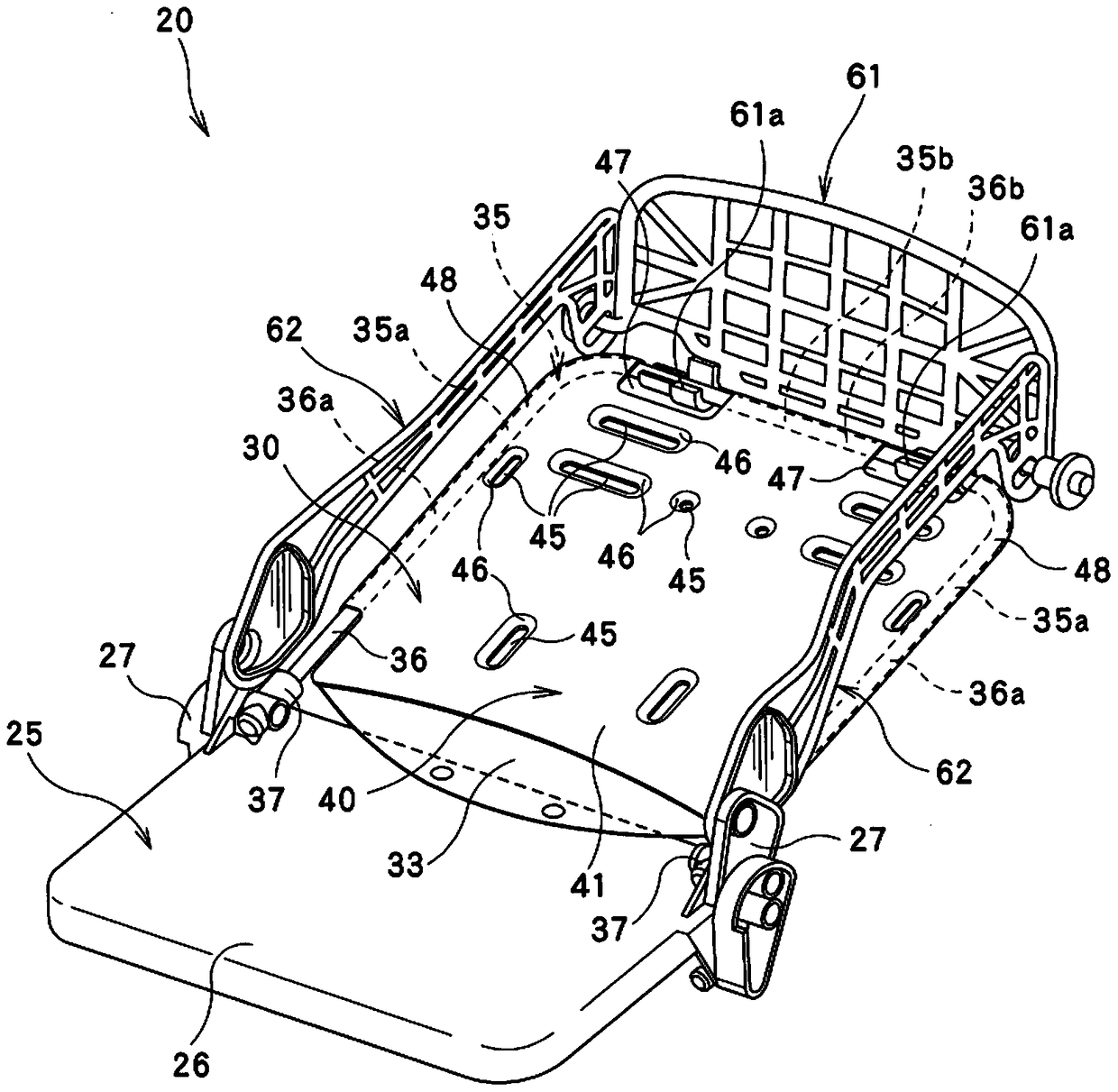

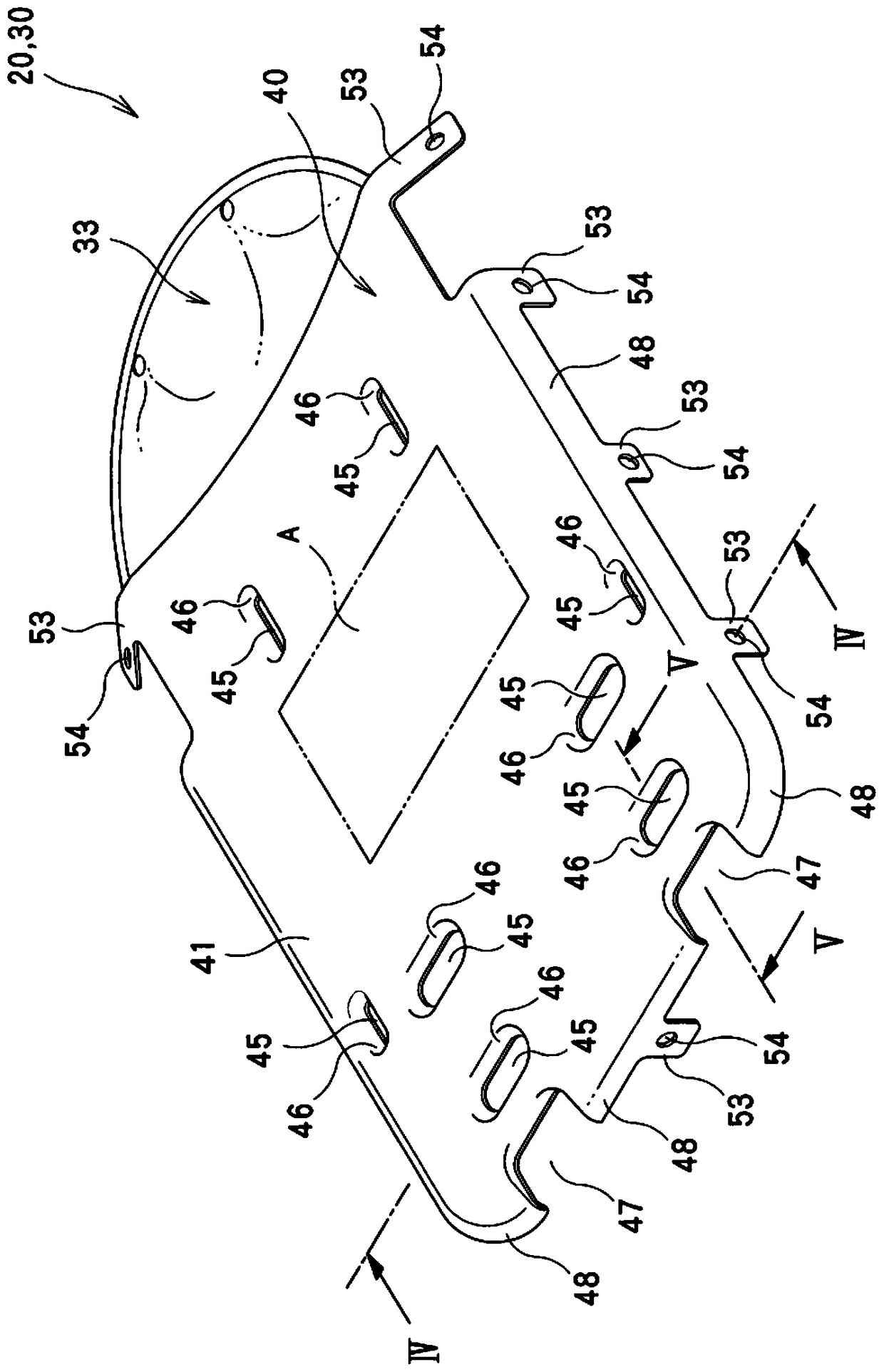

Seat support unit and stroller

InactiveCN104176100BCheap and easy to manufactureAvoid deformationVehicle seatsCarriage/perambulator accessoriesEngineeringNonwoven fabric

A seat support unit (20) is used for a stroller (10) and supports a seat. The seat support unit comprises a frame element (35) and a loading plate element (40) attached to the frame element. The loading plate element includes a nonwoven fabric (42) and a pair of fabrics (41, 43) located on both sides of the nonwoven fabric.

Owner:COMBI CORP

Roll outer material for rolling and composite roll for rolling

ActiveCN109641251BCheap and easy to manufactureImprove wear resistanceRollsMetal rolling arrangementsMaximum diameterAlloy

The present invention provides a roll outer layer material and a rolling composite roll having remarkably improved wear resistance. The material of the outer layer of the roll has a W-Co-based alloy, and the composition is as follows: a gradient composition in which the W content decreases radially from the outer peripheral side to the inner peripheral side, and the surface of the outer layer material at a position corresponding to the maximum diameter when rolling is used , in terms of mass%, containing W: 25-70%, Co: 5-45%, and further containing C: 0.6-3.5%, Si: 0.05-3%, Mn: 0.05-3%, Mo: 1-15% , and the remainder consists of unavoidable impurities. The roll outer layer material is preferably centrifugally cast.

Owner:JFE STEEL CORP

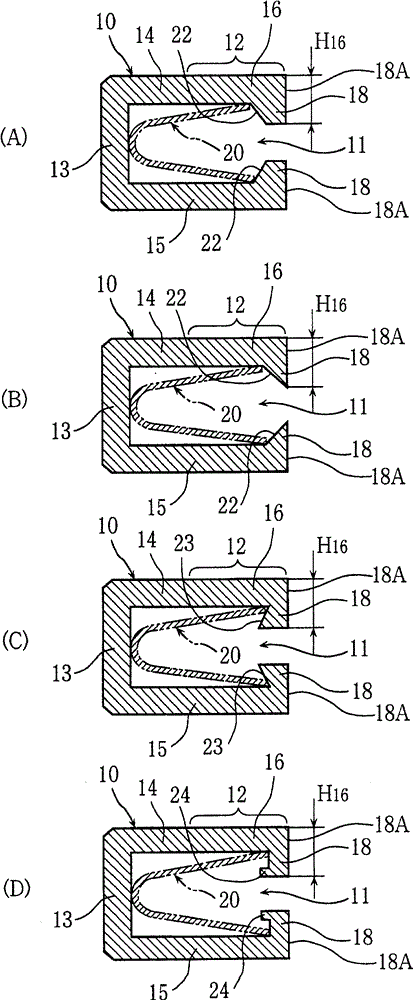

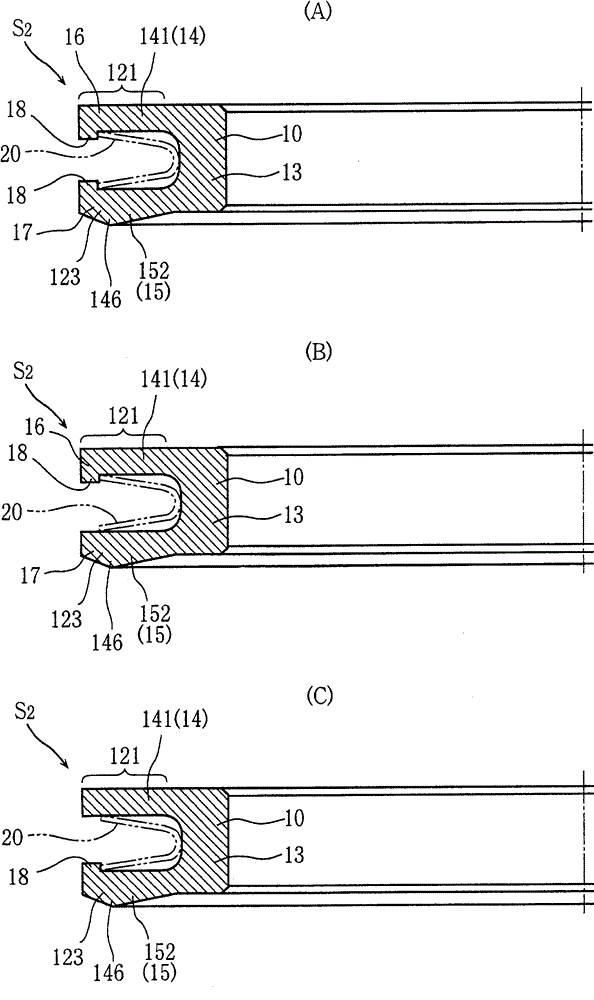

U-shaped sealing member

ActiveCN102313018BImprove sealingIncreased durabilityEngine sealsSealing arrangement for pumpsElastomerEngineering

The invention provides a U-shaped sealing member which achieves excellent stability in terms of sealing of a sealed plane of a scroll compressor and so on which make eccentric rotation. The U-shaped sealing member comprises a sealing member body (10) which has a U-shaped cross section and is made of resin, and a built-in elastic body (20) which is placed in a groove (11) of the sealing member body (10) and is made of metal. The seal portion (12) (12) of the sealing member body (10) contacted with the sealed plane (21) (21) has no projecting portion and is in the shape of a flat plane.

Owner:MITSUBISHI CABLE IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com