Method of calibrating a component placement machine, device suitable for carrying out such a method, and calibration component suitable for use in such a method or device

A technology of components and machines, applied in the field of devices implementing such a method, calibrating components, which can solve problems such as misplacement of components, mutual position offset, complex calibration methods and devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

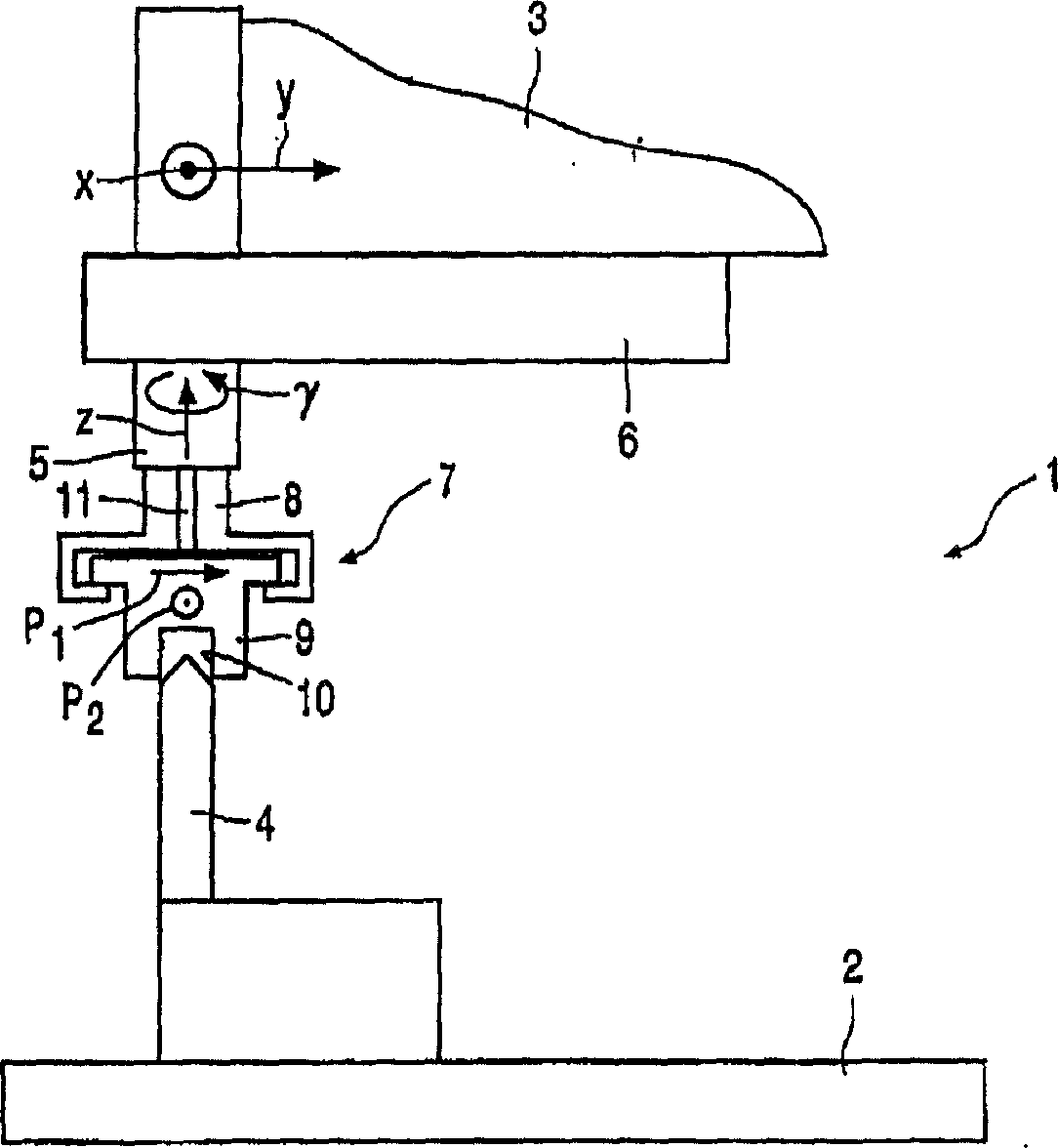

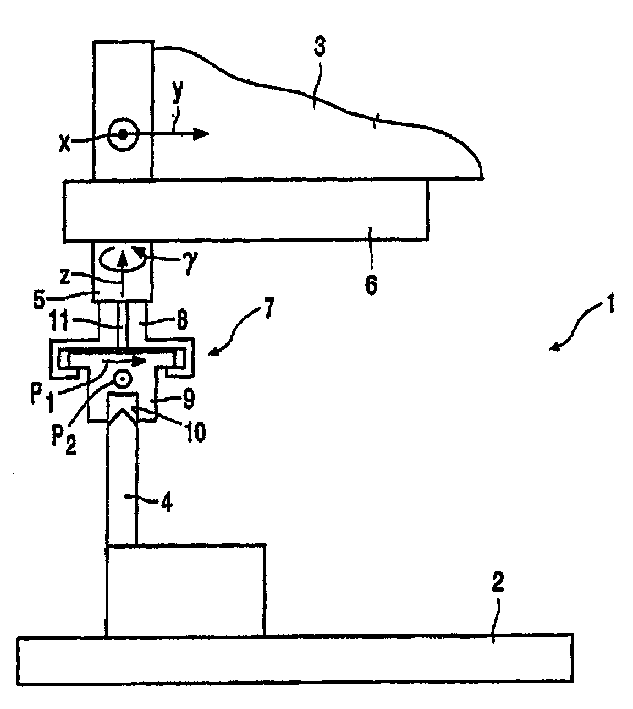

[0022] figure 1 A component placement machine 1 is shown, which is known per se and is provided with a substrate holding device 2 and a robot 3 displaceable relative to the substrate holding device 2, the substrate holding device 2 being provided with a reference element 4, which The reference element 4 comprises at least one pin and is adapted to align a substrate (not shown) with the substrate holder 2 .

[0023] The automatic machine 3 can be displaced in the X and Y directions. The automatic machine 3 is provided with a clamping device 5 that can be displaced in the Z direction relative to the automatic machine 3 and can also rotate in a Φ direction. The automatic machine 3 is further provided with A laser measuring device 6 . Part placement machines as described are known per se until now.

[0024] However, the component placement machine 1 according to the invention further comprises a calibration component 7 having a first part 8 and a second part 9 which can be align...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com