PRECIPITATION HARDENING-TYPE Ag-Pd-Cu-In-B-BASED ALLOY

A precipitation hardening and alloying technology, which is applied in the field of precipitation hardening Ag-Pd-Cu-In-B alloys, can solve the problems of easy wear and easy breakage of contact probe pins, and achieve high reliability and stable mechanical strength and wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

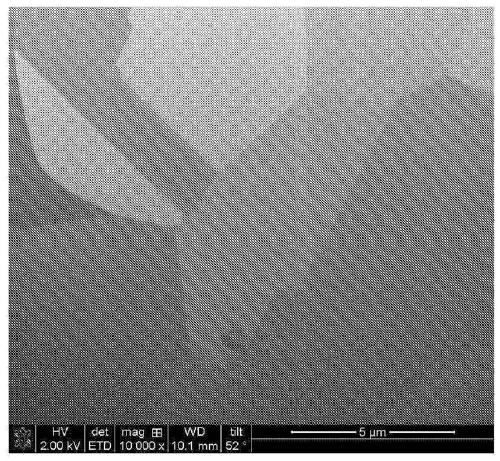

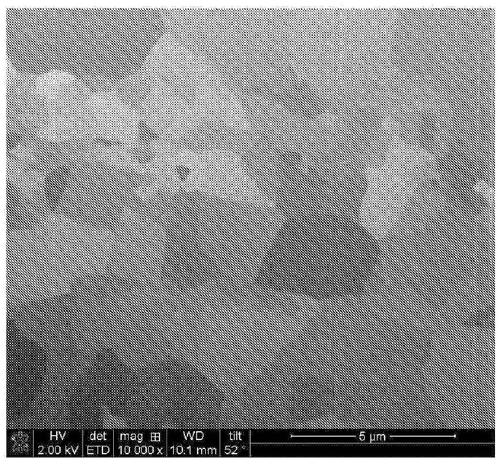

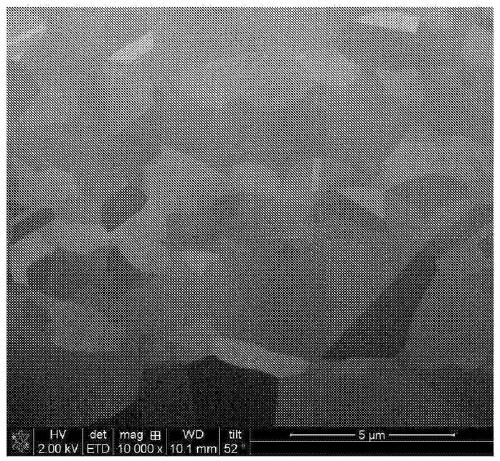

Image

Examples

Embodiment

[0056] Ag, Pd, Cu, In, and B were formulated into various desired compositions, and then an ingot (Φ15mm×L100mm) was produced by high-frequency melting. Table 1 describes the composition in each Example and Comparative Example. Note that Comparative Examples 19 and 20 show the composition of a conventional Ag-Pd-Cu-based alloy, and Comparative Example 21 shows the composition of a conventional Ag-Pd-Cu-In-based alloy.

[0057] Each composition was quantitatively analyzed, and In and unavoidable impurities which were the remainder of the composition were expressed as Balance (Bal.).

[0058] It should be pointed out that the production method of the ingot based on the present invention is not limited to high-frequency melting, for example, any melting method established now and in the future such as gas melting, electric furnace, vacuum melting method, continuous casting method, and zone melting method can be applied to this invention.

[0059] Table 1

[0060]

[0061] N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com