Process for production of phosphoric acid compound, and process for production of secondary battery

A technology of phosphoric acid compound and manufacturing method, which is applied to phosphorous compounds, chemical instruments and methods, battery electrodes, etc., can solve the problems of narrow vitrification range, difficult control of LiMPO4 particle composition, etc., and achieves excellent reliability, low cost and simple manufacturing characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] (Preparation of solid particles of compound (Y))

[0086] The solid particles of compound (Y) are obtained as follows: a compound containing element A, a compound containing element M, and a compound containing P are prepared to form a compound having the composition represented by the aforementioned formula (4) to form a raw material mixture. The raw material mixture is obtained by heating the above-mentioned raw material compound to react. The crystalline particles are preferably produced by mixing a compound containing element A, a compound containing element M, and a compound containing P while being pulverized, and reacting them in a solid phase reaction. In addition, the crystalline particles can also be obtained by a method of slowly cooling and crystallizing a raw material mixture after melting, or a method of heating and crystallizing an amorphous substance of the compound (Y). Amorphous particles are preferably produced by mixing a compound containing element A,...

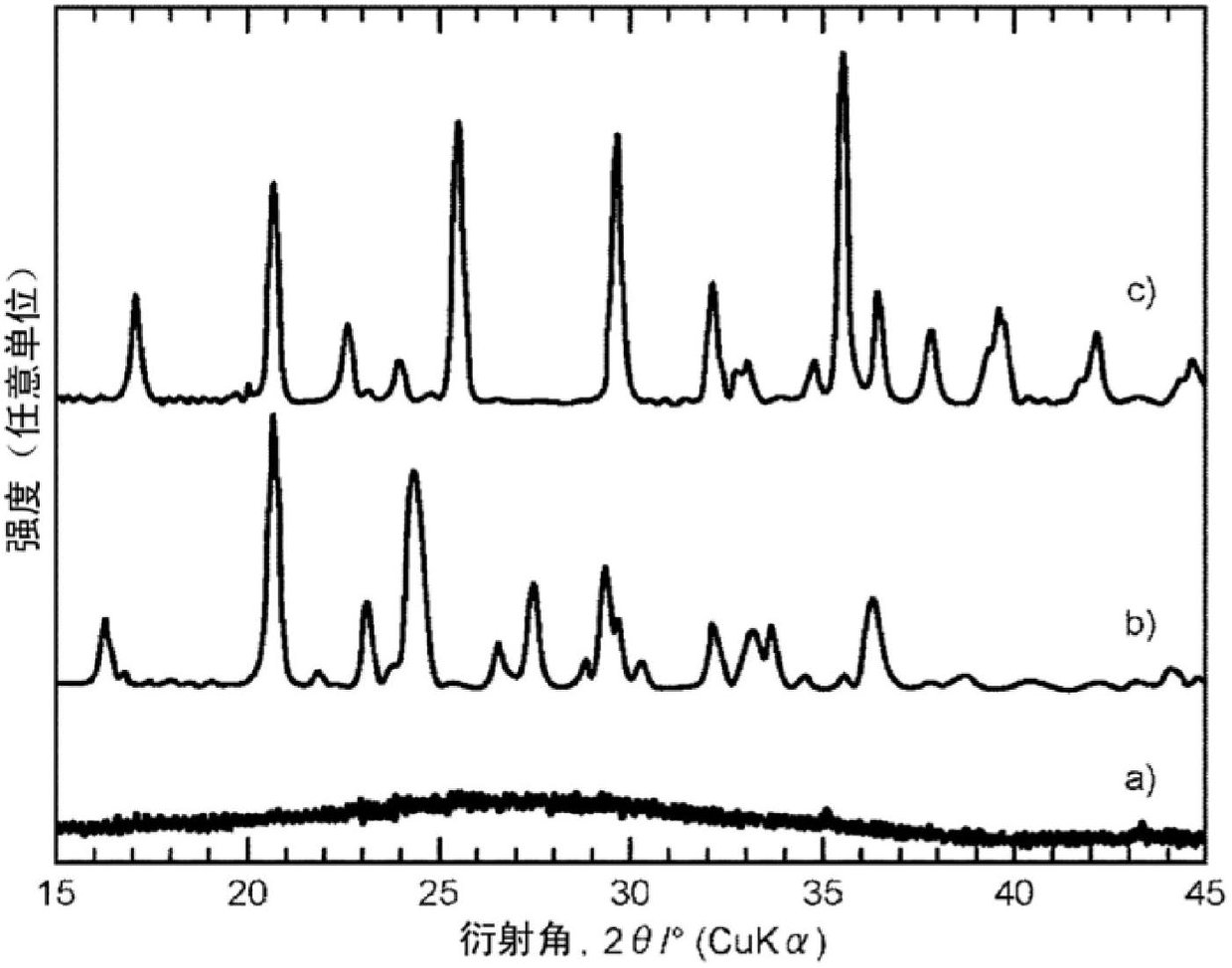

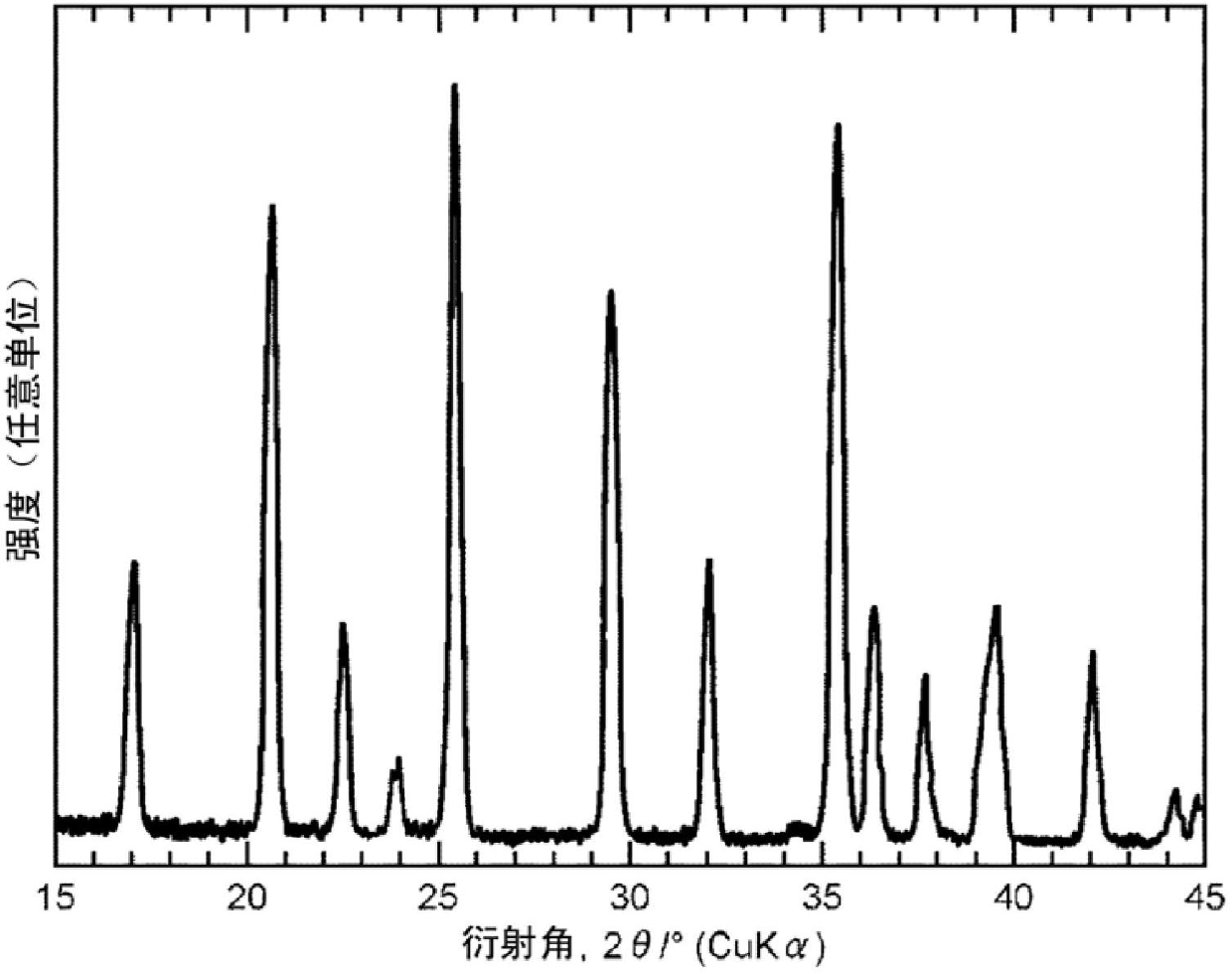

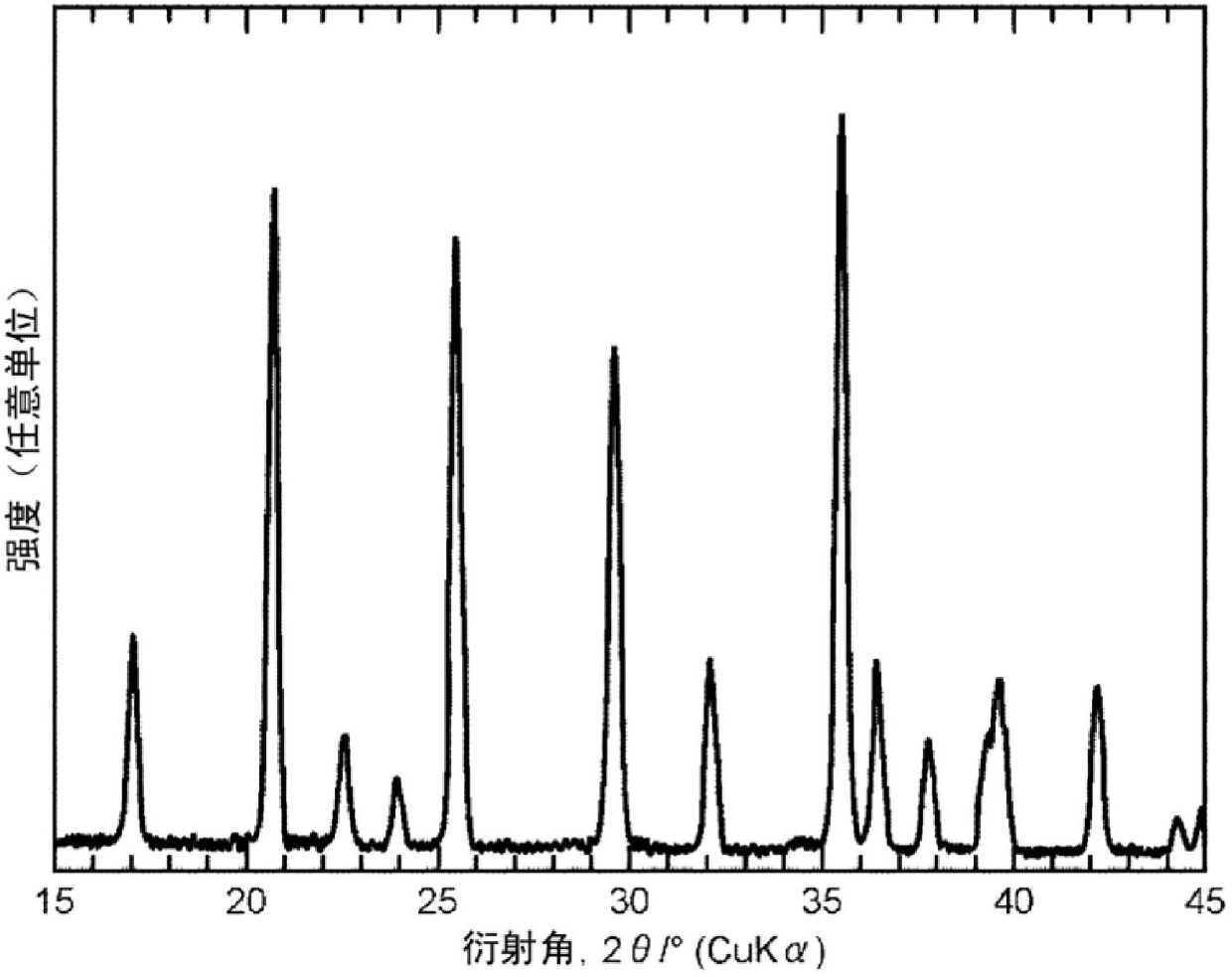

Embodiment 1)

[0155] Weigh lithium carbonate (Li 2 CO 3 ), iron trioxide (Fe 2 O 3 ) And ammonium dihydrogen phosphate (NH 4 H 2 PO 4 ) To make it Li 3 Fe 2 P 3 O 12 The composition shown is such that the molar ratio of each raw material is 3:2:6, and ethanol is used as a medium for wet grinding and mixing. After heating the mixture in air at 350°C for 2 hours, it was cooled to room temperature and crushed by a dry method. The resulting crushed material was heated in the air at 700°C for 8 hours to obtain Li 3 Fe 2 P 3 O 12 Powder of the compound shown in composition. The mineral phase of the obtained compound was identified with an X-ray diffraction device, and the result was compared with the existing Li 3 Fe 2 (PO 4 ) 3 (PDF No. 01-078-1106) The diffraction pattern is similar to the diffraction pattern.

[0156] Next, mix with Li 3 Fe 2 P 3 O 12 The crystalline compound of the composition shown is combined with iron trioxide (Fe 2 O 3 ) To make 2:1 based on the molar ratio of the oxide, and...

Embodiment 2)

[0159] The compound obtained in Example 1 has Li 3 Fe 2 P 3 O 12 The compound of the shown composition and iron trioxide (Fe 2 O 3 ) So that the molar ratio based on the oxide is 2:1, and carbon black and glucose are further added to the formulation, so that the mass ratio of the formulation to carbon black to glucose is 90:5:5. They are crushed and mixed by wet method using water as the medium. After the resulting mixture was dried at 110°C, it was heated under the same conditions as in Example 1 to obtain a carbon-containing LiFePO 4 Particles of phosphoric acid compound of the composition shown. The diffraction pattern of the obtained particles is similar to the existing LiFePO 4 The diffraction pattern of (PDF No. 01-083-2092) is similar, and it can be confirmed that they are crystalline particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com