Resin composition and molded body formed from resin composition

A resin composition and molding technology, applied in the field of moldings, can solve problems such as changing physical properties, and achieve the effects of simple manufacturing, excellent mechanical properties, and excellent chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0182] Hereinafter, although an Example demonstrates this invention, this invention is not limited to these Examples.

[0183] In addition, "part" and "%" in an Example represent "part by mass" and "% by mass".

[0184] [Evaluation method]

[0185] Each evaluation in an Example and a comparative example was implemented by the following method.

[0186] (Evaluation method of resin composition)

[0187] (1) Determination of molecular weight and molecular weight distribution

[0188] The mass average molecular weight (Mw) and the number average molecular weight (Mn) were measured using gel permeation chromatography (GPC) (manufactured by TOSOH Corporation, trade name: HLC-8220) under the following conditions.

[0189] Column: Connect TSK GUARD COLUMN SUPER HZ-L (4.6×35mm) and 2 pieces of TSK-GELSUPER HZM-N (6.0×150mm) in series

[0190] Eluent: THF

[0191] Measuring temperature: 40℃

[0192] Flow rate: 0.6mL / min

[0193] In addition, Mw and Mn were calculated|required using...

Embodiment 2

[0263] A granular molding material was prepared in the same manner as in Example 1 except that the blending amount of PVDF was changed to 30 parts and the blending amount of the copolymer (Y-2) was changed to 70 parts.

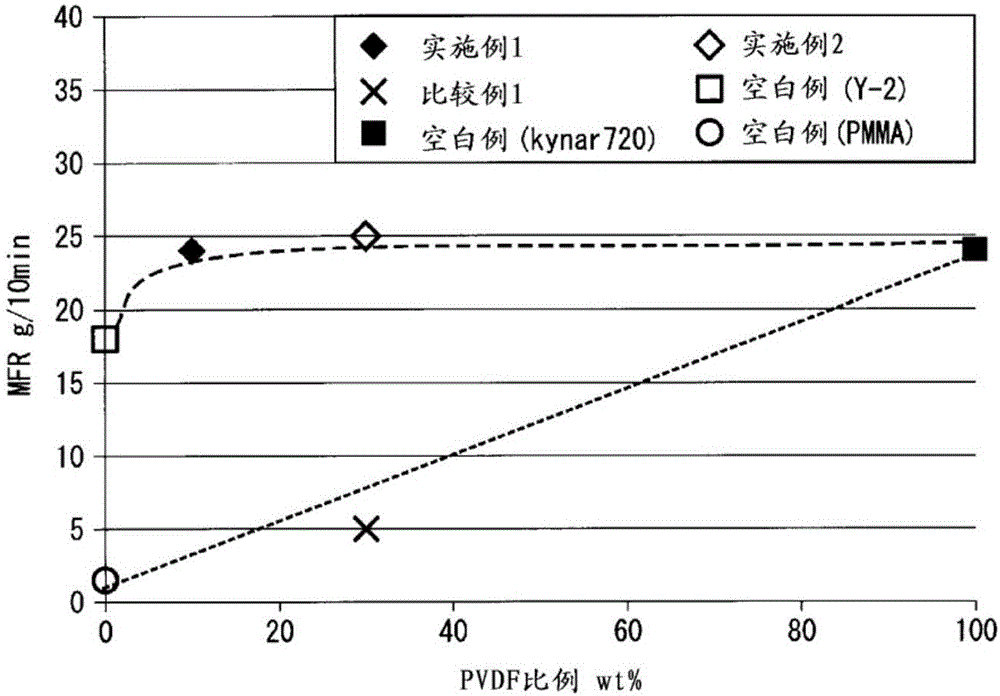

[0264] The melt mass flow rate of the obtained granular molding material was measured, and compared with the measured values of the polymer X and the copolymer (Y-2) alone. In addition, the crystal melting enthalpy of the block of the molding material (resin composition) was measured. The results are shown in Table 3 and figure 1 .

[0265]

[0266] A granular molding material was prepared in the same manner as in Example 1 except that 70 parts of commercially available PMMA (manufactured by Mitsubishi Rayon Corporation, trade name: ACRYPET VH001) was used instead of the copolymer (Y-2).

[0267] The melt mass flow rate of the obtained granular molding material was measured and compared with the individual measured values for polymer X and PMMA. In ad...

Embodiment 3

[0274] [Preparation of resin composition]

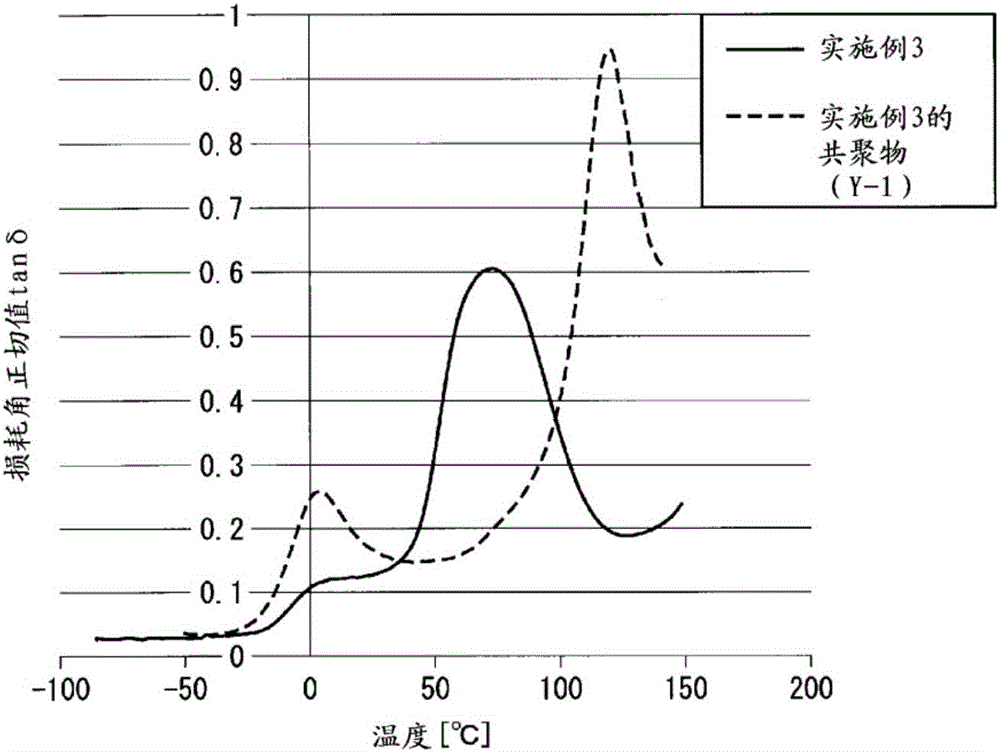

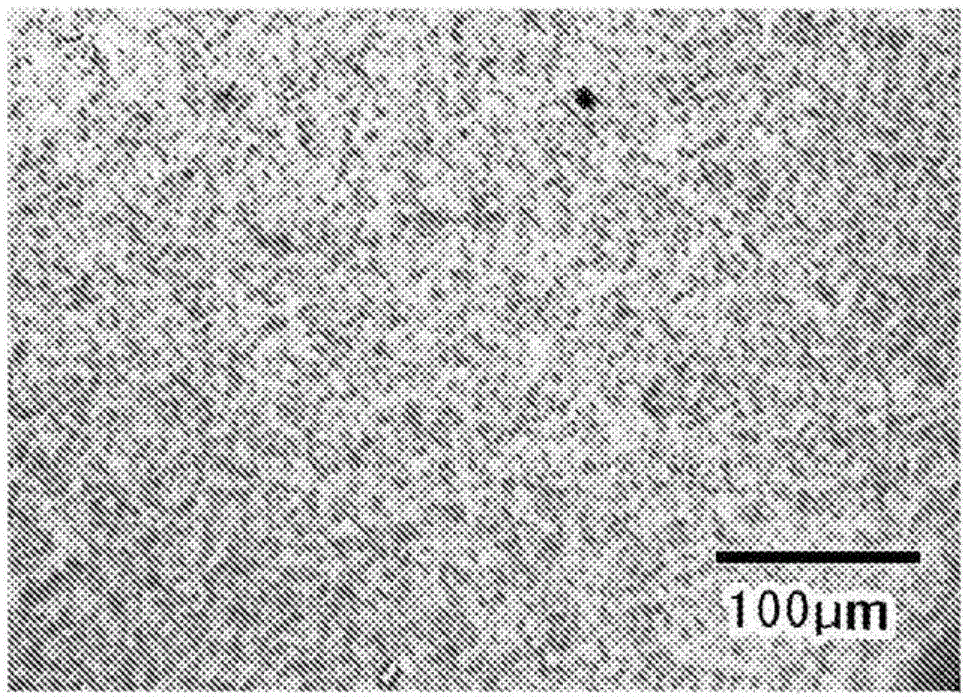

[0275] 40 parts of PVDF (manufactured by Arkema Co., Ltd., trade name: kynar720) as polymer X and 60 parts of copolymer (Y-1) produced in Production Example 3 as polymer Y were preliminarily dried at 80° C. overnight, After dry blending, it was extruded at a maximum temperature of 220° C. using a φ30 mm twin-screw kneading extruder (manufactured by Werner & Pfleiderer) to obtain a granular molding material (resin composition).

[0276] [Production of moldings]

[0277] Using the molding material obtained as described above, injection molding was performed with an injection molding machine (manufactured by Toshiba Corporation, trade name: IS100) at a resin temperature of 220° C. and a mold temperature of 40° C. to obtain a molded body with a thickness of 3 mm.

[0278] The crystalline melting enthalpy, total light transmittance (TT), haze (HZ), elastic modulus, elongation at break, and Charpy impact value of the obtained molded body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com