Method for manufacturing food emulsion having controlled physical properties

A manufacturing method, food technology, applied in the direction of food science, etc., can solve problems such as physical property deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

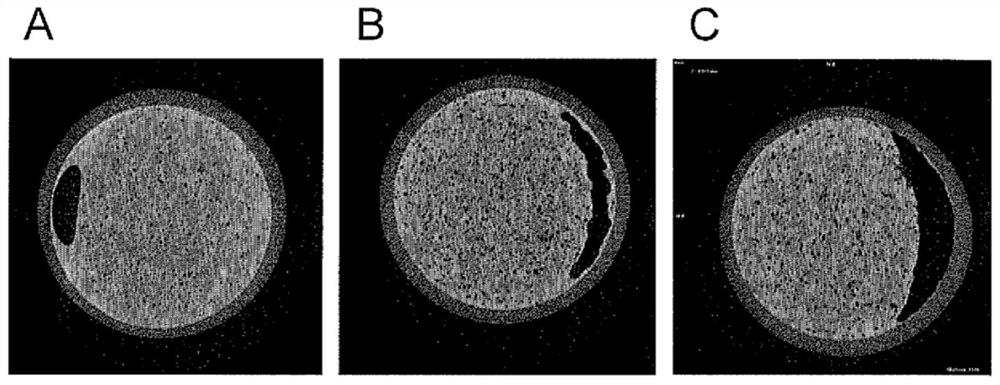

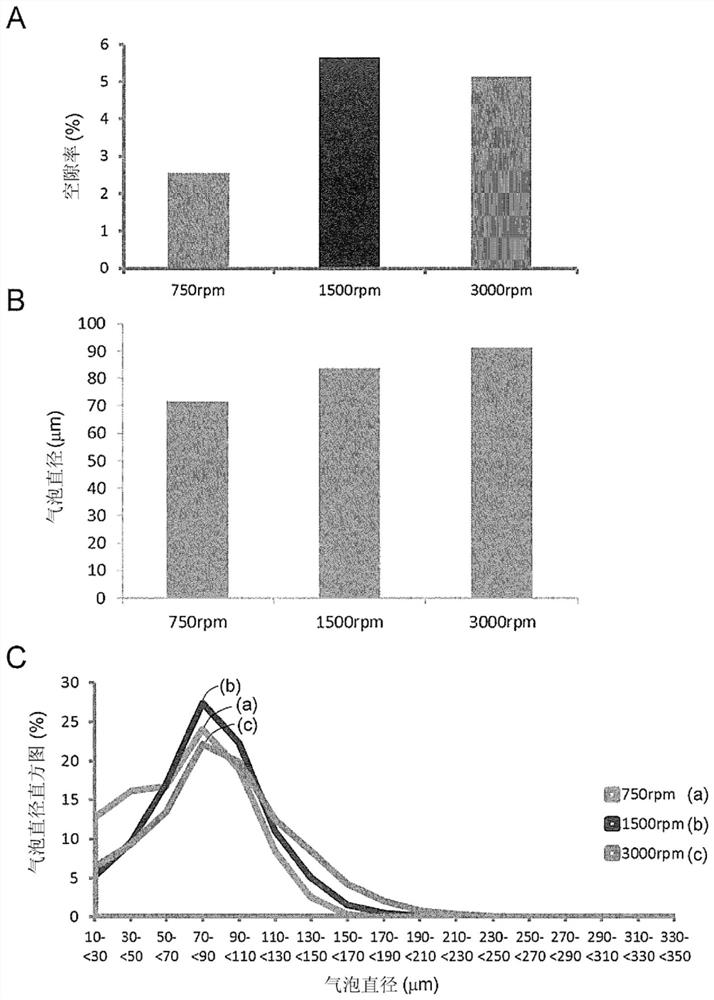

[0183] [Example 1] Observation of tissue structure based on X-ray micro-CT

[0184] 1. Summary

[0185] The stabilization of the physical properties of the simple material protein 21 series was studied, and it was clarified that stirring conditions (time, speed) affect the hardness. Since the difference in the microstructure is considered to be a factor of the change in physical properties, samples with different stirring speeds were observed. As a result, the diameter of the bubbles increases as the stirring speed increases, but the amount of voids becomes constant at a certain speed or higher.

[0186] 2. Method

[0187] (1) device

[0188] SKYSCAN 1172 (manufactured by BRUKER)

[0189] (2) Sample

[0190] Each raw material was charged into a vacuum-cooled high-speed mixer (UMC5 type manufactured by STEPHAN Co., Ltd.), and the stirring rate at room temperature was changed (3000 rpm, 1500 rpm, 750 rpm) and mixed. Then, flow the sample into the h: 65mm plastic tube, he...

Embodiment 2

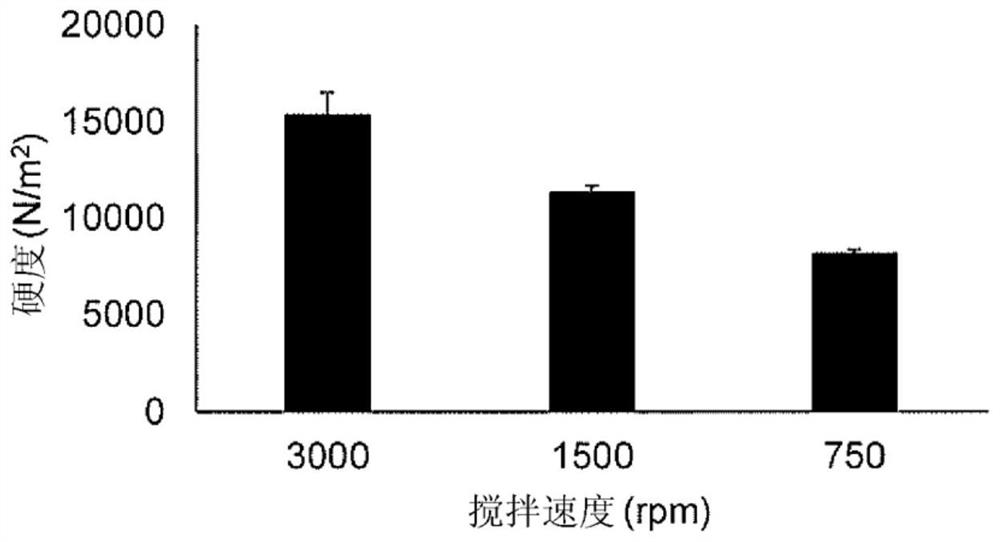

[0198] [Example 2] Test based on emulsified food model

[0199] (Water: 41.9%, Oil: 18.2%, Protein: 39.9%)

[0200] 1. Summary

[0201] Mechanisms related to changes in physical properties due to physical treatment were studied by using model foods of protein, oil, and water as simple materials of the protein 21 series. As a result of the verification, it is considered that the main reasons for the change of the physical properties of the model food are (1) the size of the emulsified oil droplets (fat globules), (2) the ratio of pores, and (3) the tissue structure of the protein. and (3) for visual and numerical verification.

[0202] 2. Purpose

[0203] To elucidate the mechanism of firmness associated with physical handling (stirring time and speed) of model food products.

[0204] 3. Method

[0205] Sample preparation

[0206] Using a vacuum-cooled high-speed mixer (UMC5 manufactured by Stephan Co., Ltd.), the raw materials were put into the mixer at the same time wit...

Embodiment 3

[0239] [Example 3] Emulsified food using chicken

[0240] Summary of product coordination tests

[0241] As raw material chicken meat (common name), the chicken meat obtained by using the meat grinder (GM-D by Nippon Career Industry Co., Ltd.) and making it pass through the mesh of 2 mm was used.

[0242] The mixture was charged into a vacuum-cooled high-speed mixer (UMC5 type manufactured by STEPHAN Co., Ltd.), and mixed by changing the stirring rate at room temperature (3000 rpm, 1500 rpm, and 750 rpm). Then, flow the sample into the h: 65mm plastic tube, rapidly frozen at -40°C (about 1 hour), and heated at 95°C (core temperature 75°C or higher) for 6 minutes in a steam convection oven (MIC-5TB3 manufactured by HOSHIZAKI). The measurement was performed by standing at room temperature for 30 minutes.

[0243] The fit is shown in Table 8.

[0244] [Table 8]

[0245]

[0246] The relationship between the stirring speed and the hardness after heating is shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com