Method for producing spherical activated carbon

A manufacturing method, activated carbon technology, applied in chemical instruments and methods, carbon compounds, carbon active ingredients, etc., can solve problems such as heavy burden on patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

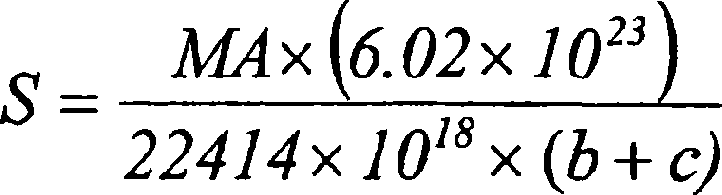

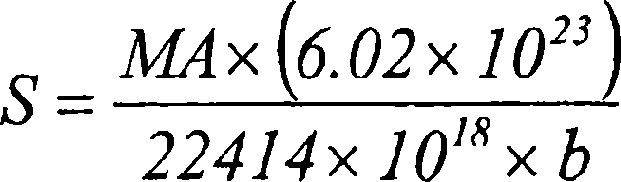

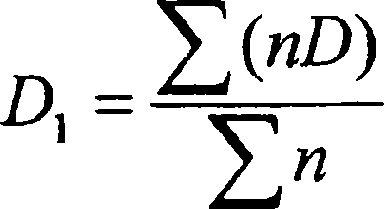

[0090] 220 g of deionized exchanged water and 58 g of methyl cellulose were put into a 1 L separable flask, and 105 g of styrene, 184 g of 57% divinylbenzene (57% divinyl benzene) were appropriately added therein. Benzene and 43% ethyl vinyl benzene), 1.68g of 2,2'-azobis(2,4-dimethylvaleronitrile), and 63g of 1-butanol as a pore-forming agent, in the system Internally replaced with nitrogen, the two-phase system was stirred at 200 rpm, heated to 55° C. and kept in this state for 20 hours. The resulting resin was filtered, dried with a rotary evaporator, and 1-butanol was removed from the resin by distillation with a vacuum drier, and dried under reduced pressure at 90° C. for 12 hours to obtain 1-butanol with an average particle diameter of 180 μm. Spherical porous synthetic resin. The specific surface area of the porous synthetic resin is about 90m 2 / g.

[0091] 100 g of the obtained spherical porous synthetic resin was charged into a reaction tube with a perforated pl...

Embodiment 2

[0094] Except for stirring the two-phase system at 200 rpm in the above-mentioned Example 1, and stirring at 100 rpm, the operation of the above-mentioned Example 1 was repeated, thereby obtaining spherical activated carbon and surface-modified spherical activated carbon. Table 1 shows the properties of the obtained spherical activated carbon, and Table 2 shows the properties of the obtained surface-modified spherical activated carbon.

Embodiment 3

[0096] Except for stirring the two-phase system at 200 rpm in the above-mentioned Example 1, and stirring at 150 rpm, the operation of the above-mentioned Example 1 was repeated, thereby obtaining spherical activated carbon and surface-modified spherical activated carbon. Table 1 shows the properties of the obtained spherical activated carbon, and Table 2 shows the properties of the obtained surface-modified spherical activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com