Ferric phosphate hydrate particle powder and process for production thereof, olivine-type lithium iron phosphate particle powder and process for production thereof, and non-aqueous electrolyte secondary battery

A technology of lithium iron phosphate and olivine type, which is applied in the field of crystalline iron phosphate hydrate particle powder and its production, can solve the problems of no mention of impurities, difficulty in increasing the density of the positive electrode of the coating film, and unfavorable volume energy density. The effect of high discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0135] The BET specific surface area is 98.5m 2 1147g of 25% slurry of hydrated iron oxide particles per g is packed into a heating type mixing mixer, and orthophosphoric acid solution is added while stirring, so that the mol ratio of P / Fe reaches 1.1, and then the mixed slurry is adjusted with deionized water The amount of liquid was adjusted to a volume of 10 L, so that the reaction concentration was 0.3 mol / L based on the iron concentration. Thereafter, the stirring blade was rotated at a peripheral speed of 2.8 m / s and a rotation speed of 900 rpm, and heated to 60° C. while stirring at a high speed, and the temperature in the mixing mixer was kept at 60° C. 16 hour response. After the reaction, the slurry taken out was washed with three times the amount of water using a filter press, and then dried at 110° C. with a ventilated dryer for 12 hours to obtain 555 g of dry powder.

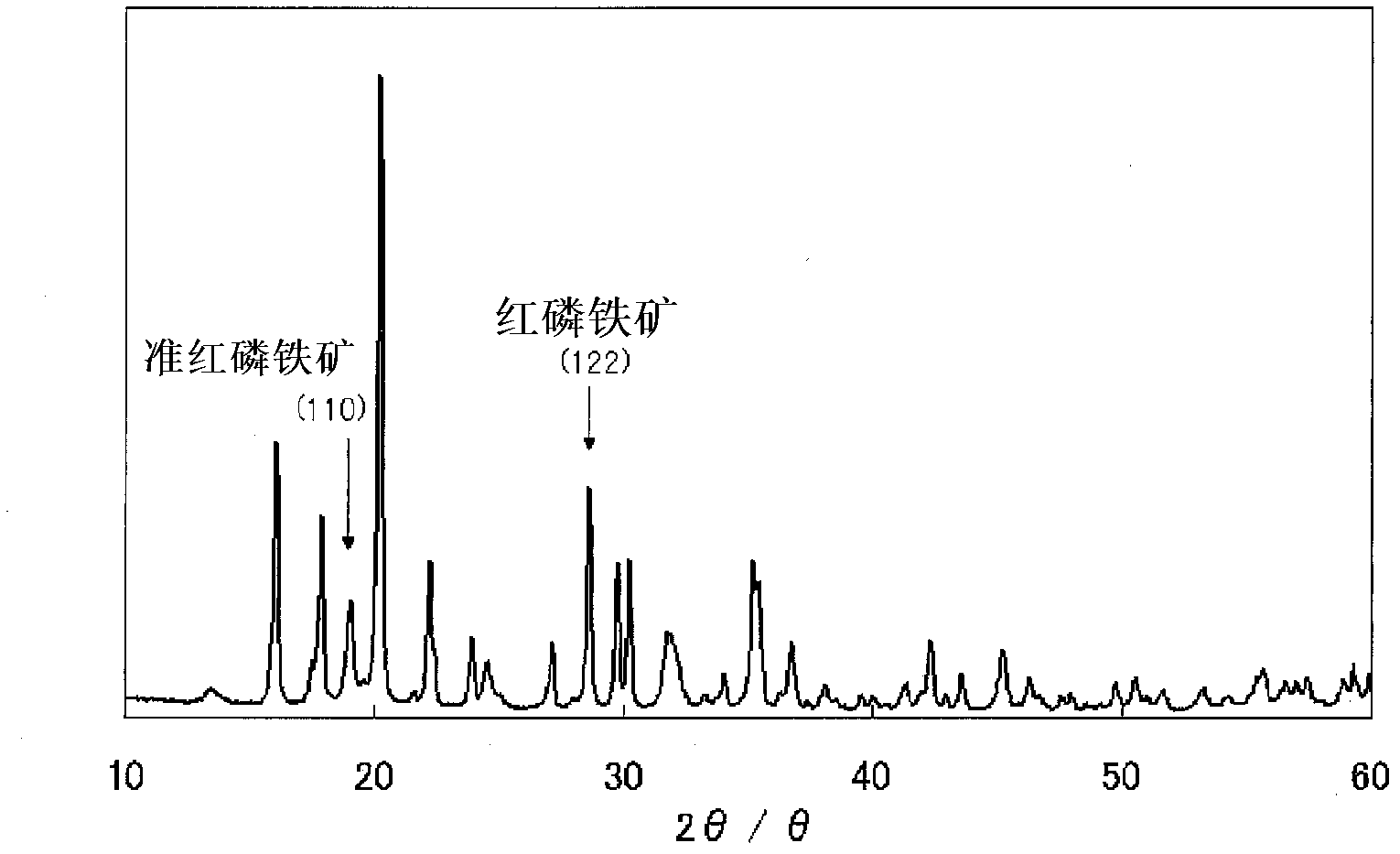

[0136] When the powder X-ray diffraction measurement was carried out, it was known that the ob...

Embodiment 2-1

[0141] Put 35 g of the ferric phosphate hydrate particle powder obtained in Example 1-1, 8.15 g of lithium hydroxide hydrate, 4.32 g of sucrose, and 120 mL of ethanol into a planetary ball mill jar made of zirconia, and then add 450 g of φ3 mm zirconia beads to Wet mixing and crushing were performed at 300 rpm for 2 hours. The slurry after the pulverization treatment was subjected to solid-liquid separation with a suction filter, and then dried at 80° C. for 6 hours with a drier.

[0142] The obtained dried product was pulverized in a mortar, calcined at 725° C. for 3 hours under a nitrogen atmosphere, and passed through a 75 μm sieve to obtain olivine-type lithium iron phosphate particles.

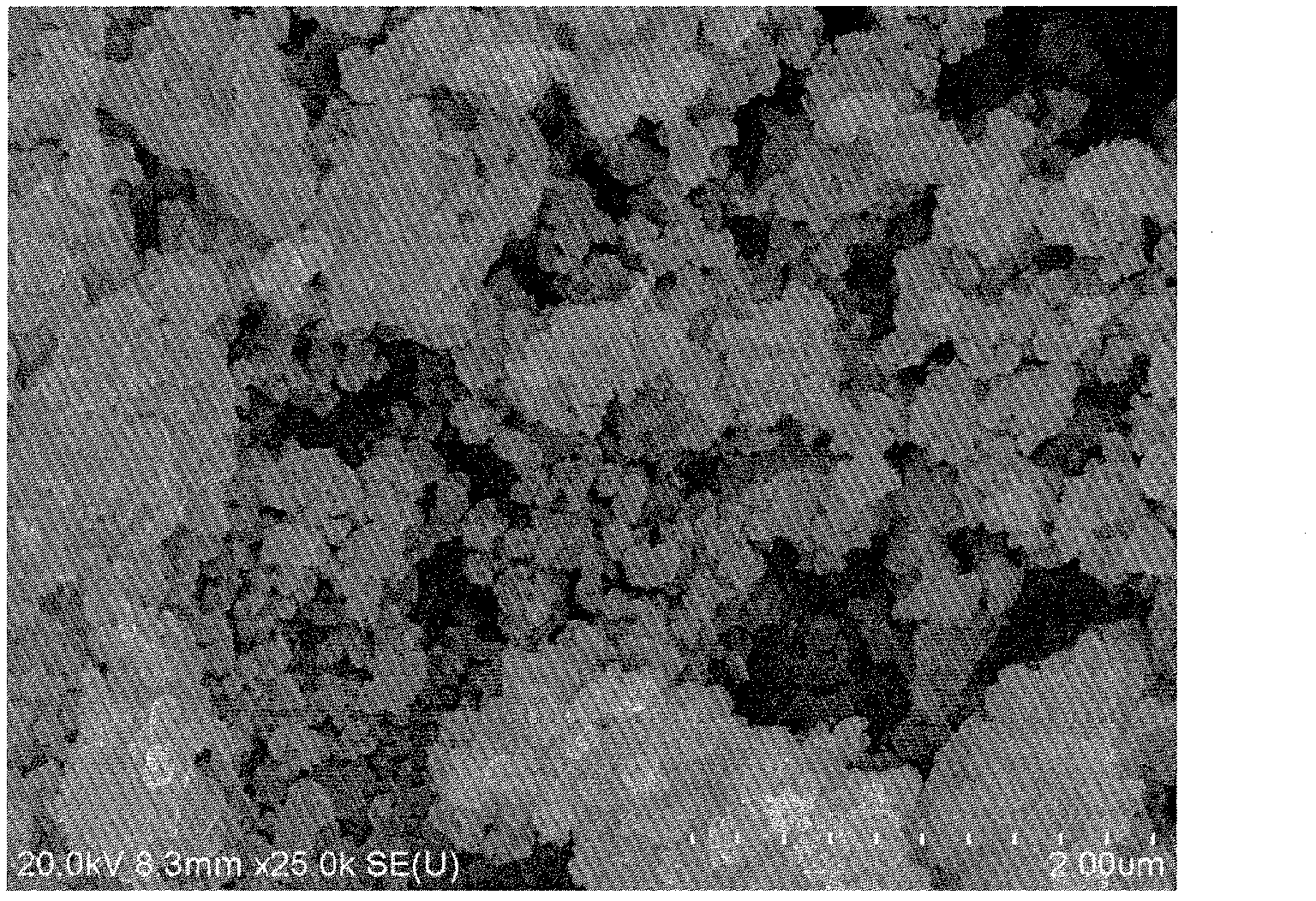

[0143] The BET specific surface area of the obtained calcined product was 31.8m 2 / g, the tap density is 0.75g / cc, the carbon content is 2.70wt%, and the Na content is 70ppm. As a result of observation with a scanning electron microscope, the average primary particle diameter was as f...

Embodiment 1-2

[0145] Except having changed the wet reaction temperature from 60 degreeC to 80 degreeC, it reacted similarly to Example 1-1, and obtained the product.

[0146] When the powder X-ray diffraction measurement was carried out, it was known that the obtained powder was composed of a compound consistent with the structure of strengite as the main phase, and a compound consistent with the structure of strengite as the second phase of ferric phosphate hydration granule powder. The (122) / (110) peak intensity ratio of the obtained powder was 1.07. In addition, impurity phases were not confirmed.

[0147] The BET specific surface area of the obtained powder was 13.8m 2 / g, Na content is 16ppm. In addition, the P / Fe molar ratio of the obtained powder was 0.98, and it was confirmed that an iron phosphate hydrate particle powder having a P / Fe molar ratio extremely close to the theoretical composition was obtained.

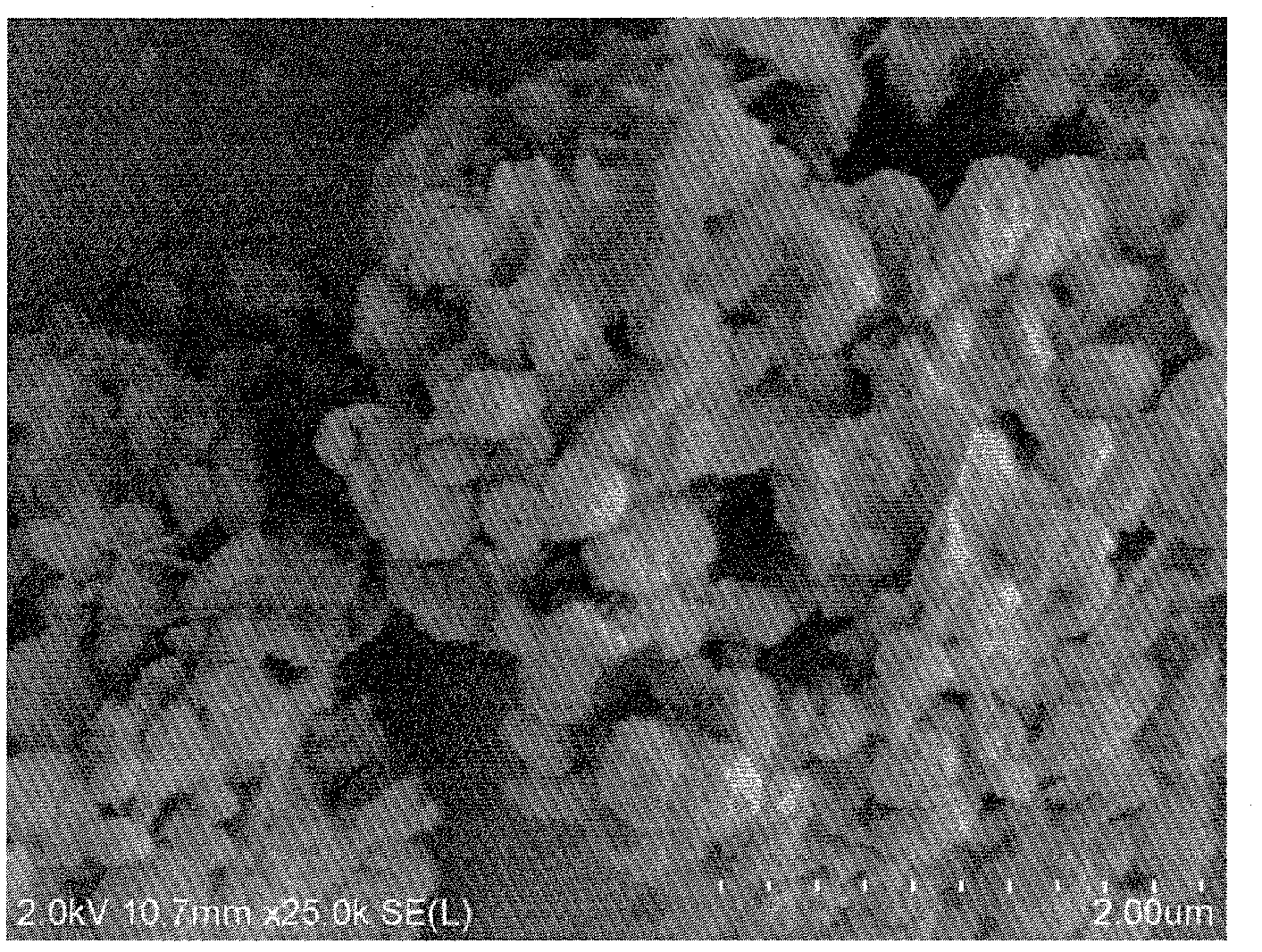

[0148] Scanning electron microscope photography of the obtained powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com