Independent suspension for vehicles, in particular suspension for directional wheel for vehicles

An independent suspension and vehicle technology, applied in the direction of suspension, elastic suspension, vehicle parts, etc., can solve the problem of suspension service life reduction, etc., to achieve the effect of easy assembly and simplified mold manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

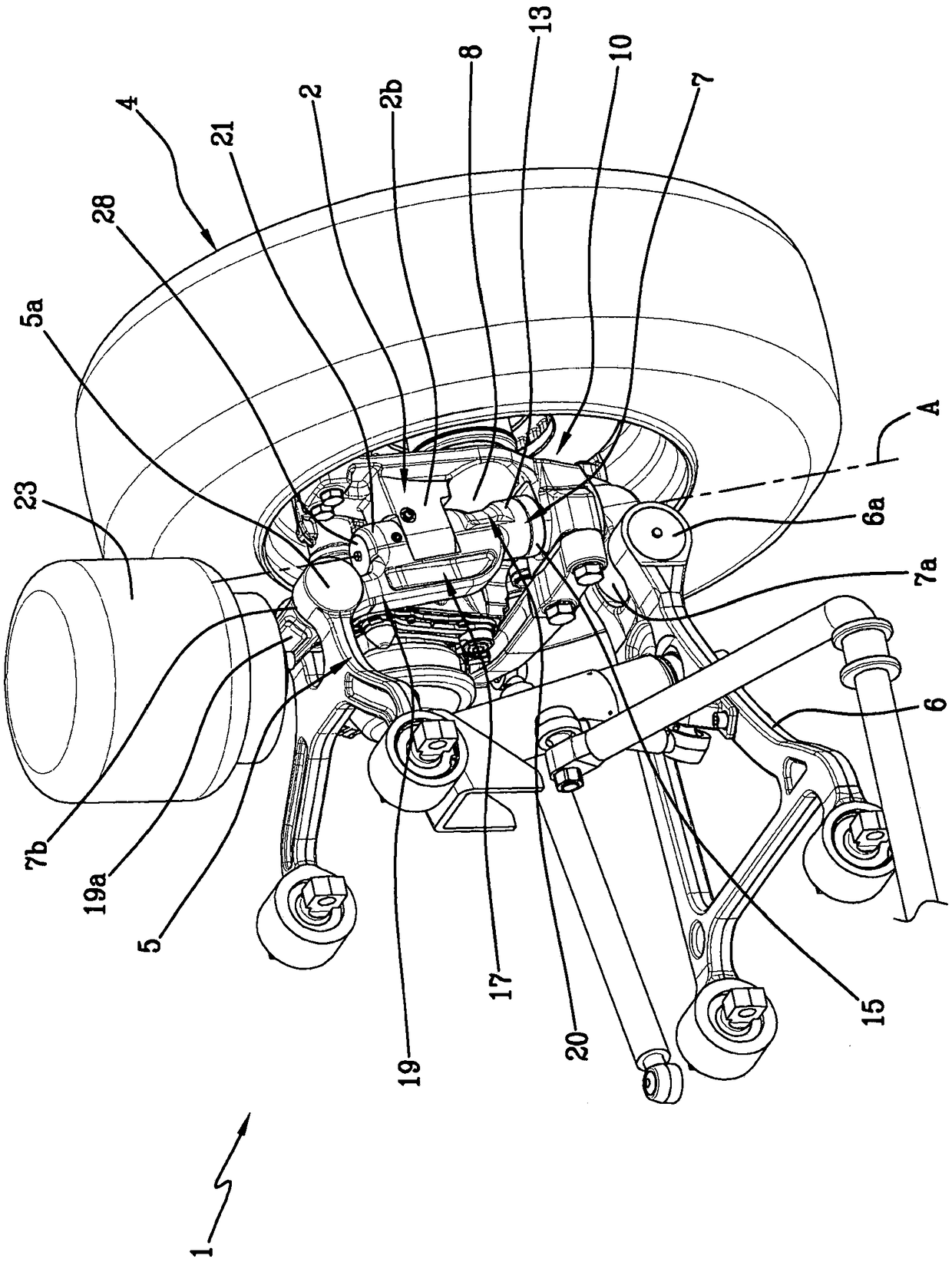

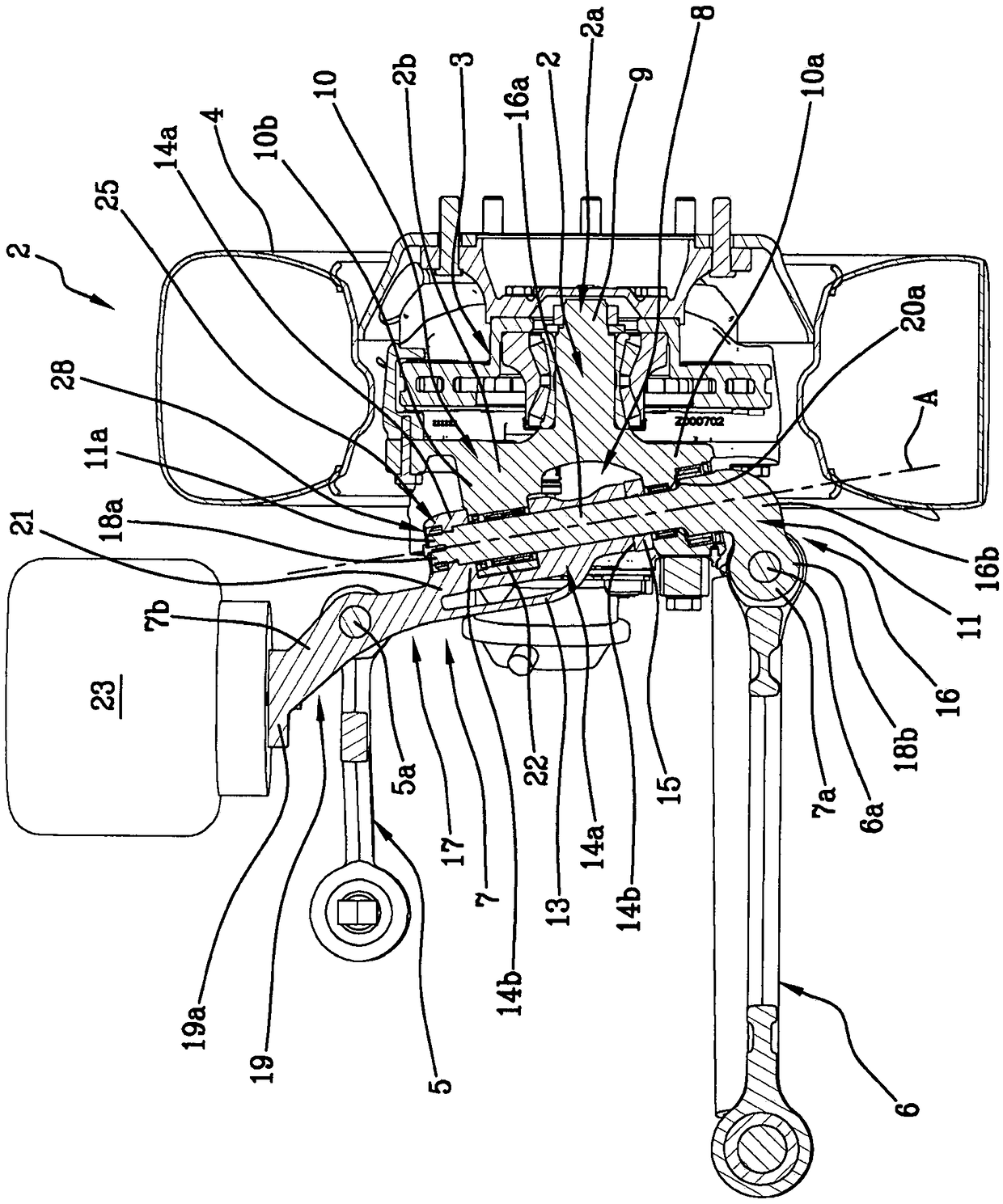

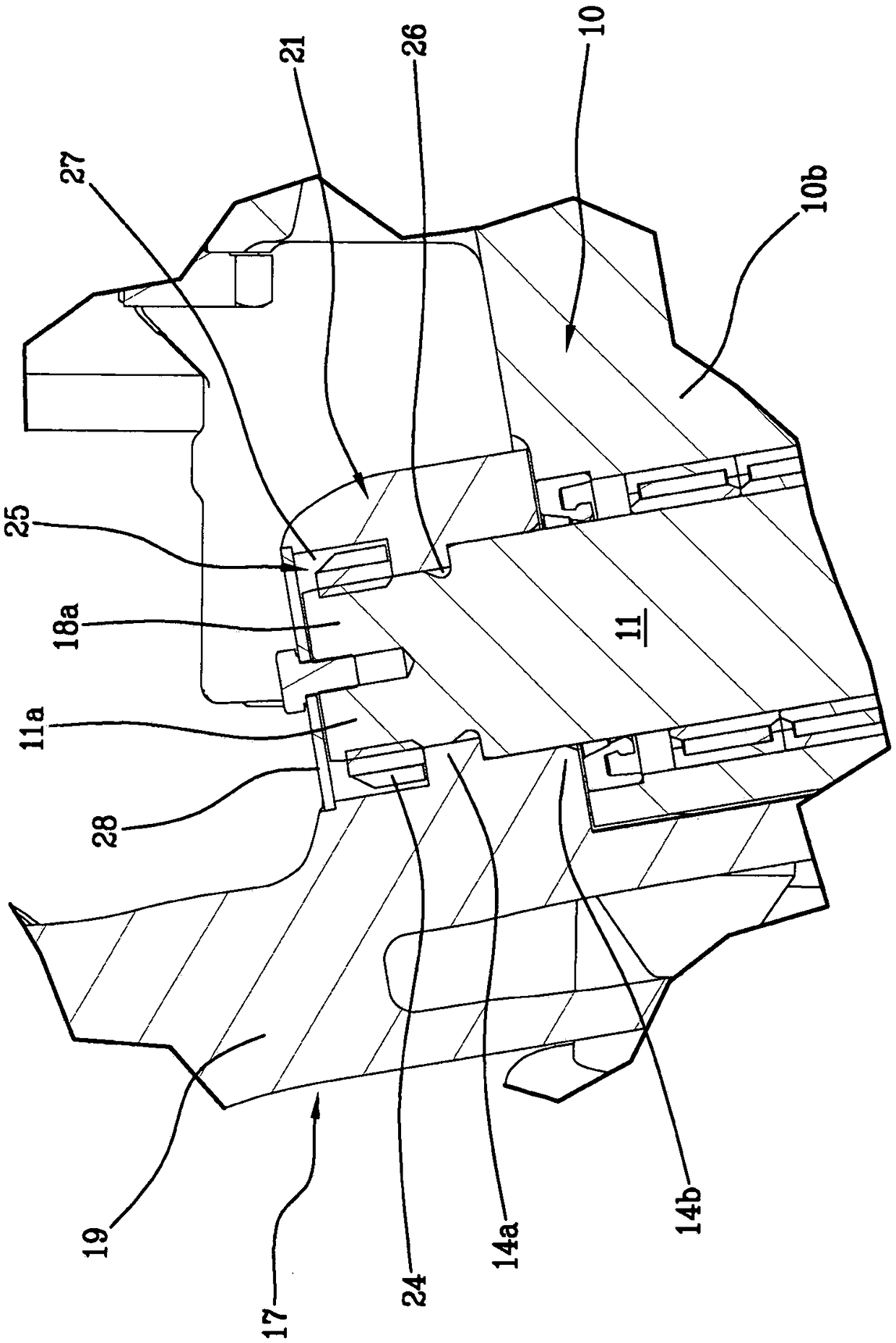

[0032] Referring to the drawings, reference numeral 1 denotes an independent suspension for a vehicle according to the present invention. As already mentioned, the term "independent suspension" is intended to define an assembly configured to allow each wheel of the same axle to move vertically (ie react to bumps on the road) independently of the other.

[0033] Preferably, the suspension 1 is a suspension for directional wheels, more preferably the front wheels of the vehicle.

[0034] The suspension mainly includes: a steering knuckle 2 (with pins), on which the hub 3 of the wheel 4 is rotatably constrained during use; a pair of cross arms, namely an upper cross arm 5 and a lower cross arm 6; And the knuckle bracket assembly 7, which is pivoted to the arm by means of specific (horizontal) articulation points 5a, 6a and is rotatably associated with the knuckle 2 to allow rotation about the steering axis "A".

[0035] The knuckle 2 extends between an outer part 2 a and an inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com