High efficiency back surface electrode-type solar cell and manufacturing method therefor

A technology for solar cells and manufacturing methods, applied in the directions of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of increased contact resistance between p-type silicon and electrodes, and achieve low resistance loss, cheap and simple resistance loss , The effect of low wiring resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

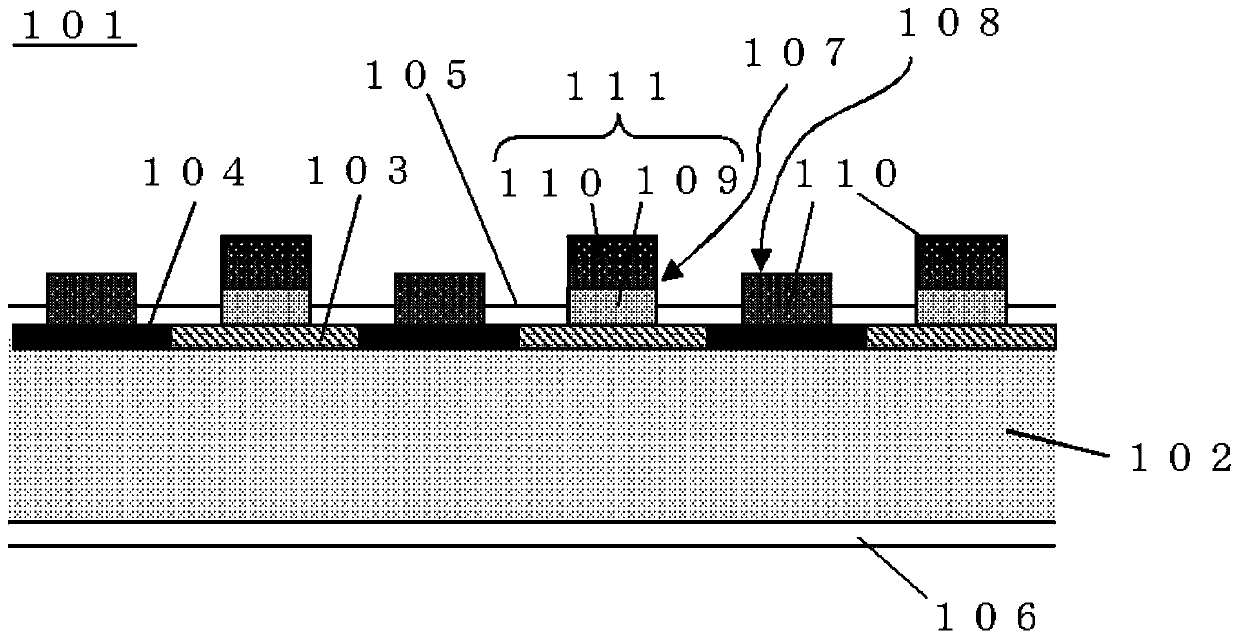

Embodiment 1

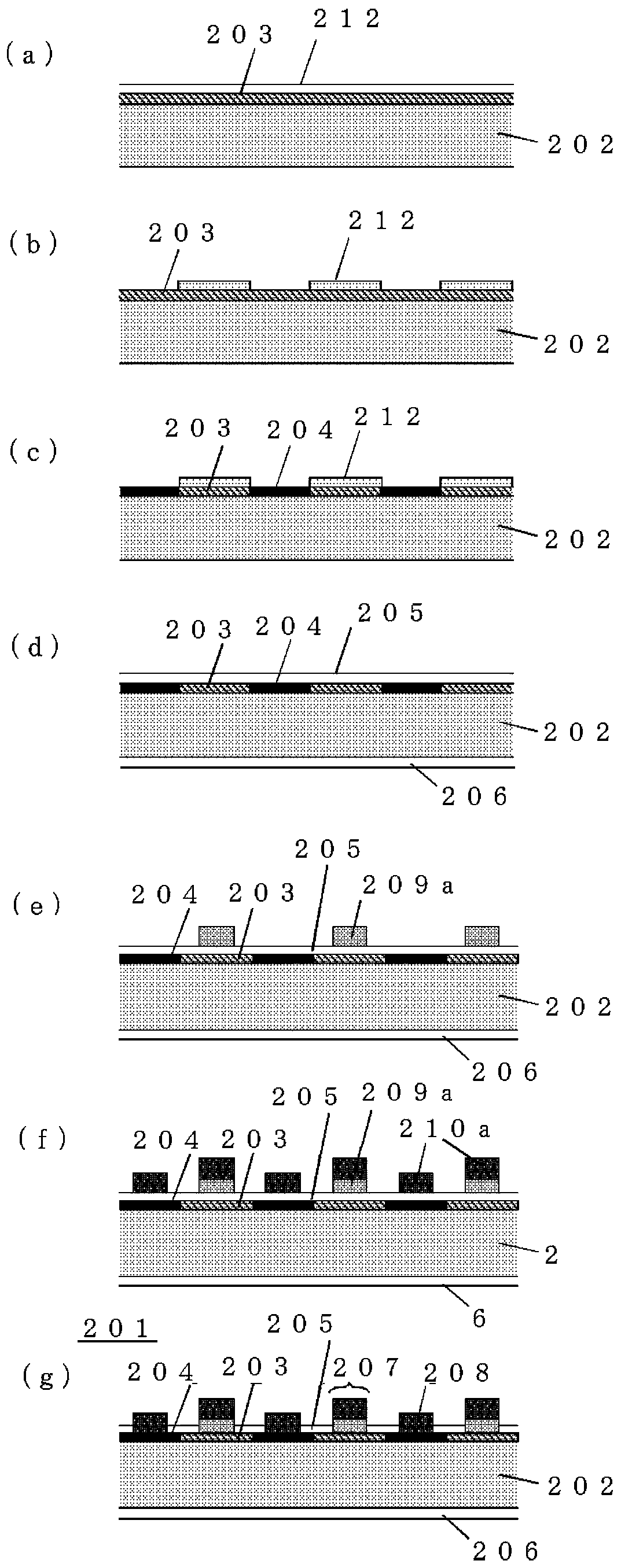

[0075] Initially, in a phosphorus-doped n-type as-cut silicon substrate with a square thickness of 150 mm, a thickness of 200 μm, and a resistivity of 1 Ω·cm, the damaged layer was removed by heating concentrated potassium hydroxide solution, and then heated in 5% potassium hydroxide at 80 ° C. Immerse in the solution for 20 minutes to form an irregular pyramid-like texture, and then wash in a hydrochloric acid / hydrogen peroxide mixed solution.

[0076] Next, the mixture of boron compound and binder is spin-coated on the back of the substrate, and boron is diffused by heat treatment at 1000°C for 30 minutes to form a p-type region, and then oxidation heat treatment is continued at 1000°C for 2 hours.

[0077] After the heat treatment, the oxide film at the position where the n-type region is formed on the rear surface of the substrate is removed linearly by irradiation with laser light having a wavelength of 532 nm.

[0078] Next, a set of two substrates with their light recei...

Embodiment 2

[0085] Operate with the same procedure as in Example 1 until a passivation film and an anti-reflection film are formed. On the obtained crystalline silicon substrate, by screen printing, mix a mixture of aluminum powder and glass frit and an organic binder to obtain The aluminum paste is coated on the p-type region and dried at 200°C for 1 minute.

[0086] Next, by screen printing, a silver paste to which no group III elements were added was applied to the dry body of the n-type region and the aluminum paste formed on the p-type region, dried at 200°C for 1 minute, and then subjected to 800°C, 3 The second heat treatment sinters the silver paste to obtain solar cells.

[0087] Finally, the output characteristics of the solar cell were measured using simulated sunlight of a xenon lamp light source type.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com