Method for producing a master disk,stamper and recording medium,and master disk, stamper and recording medium

A technology for recording media and master discs, applied in the field of master discs, can solve the problems of expensive, large equipment, insufficient temperature increase, etc., and achieve the effects of cheap manufacturing, easy manufacturing and improved resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

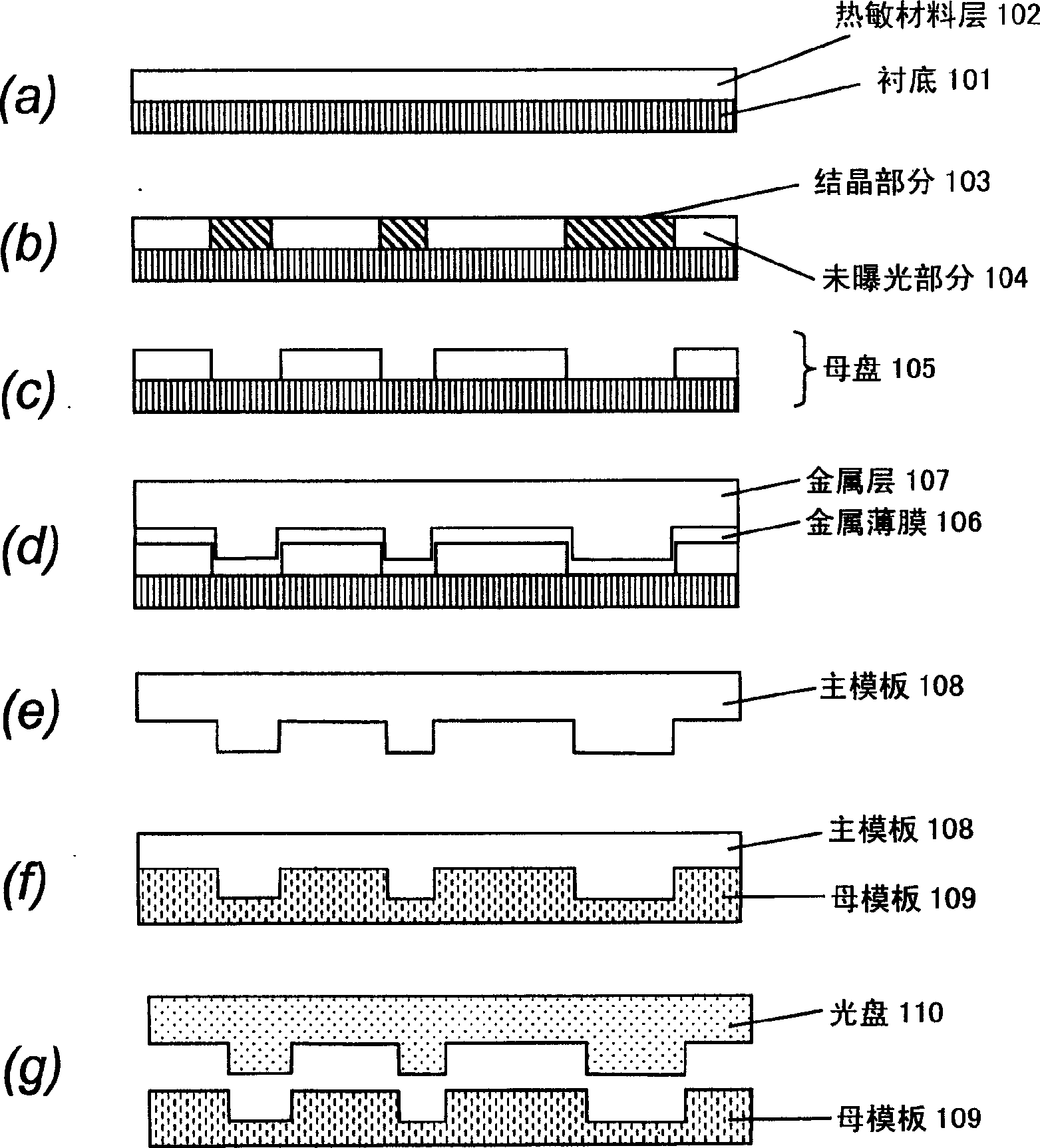

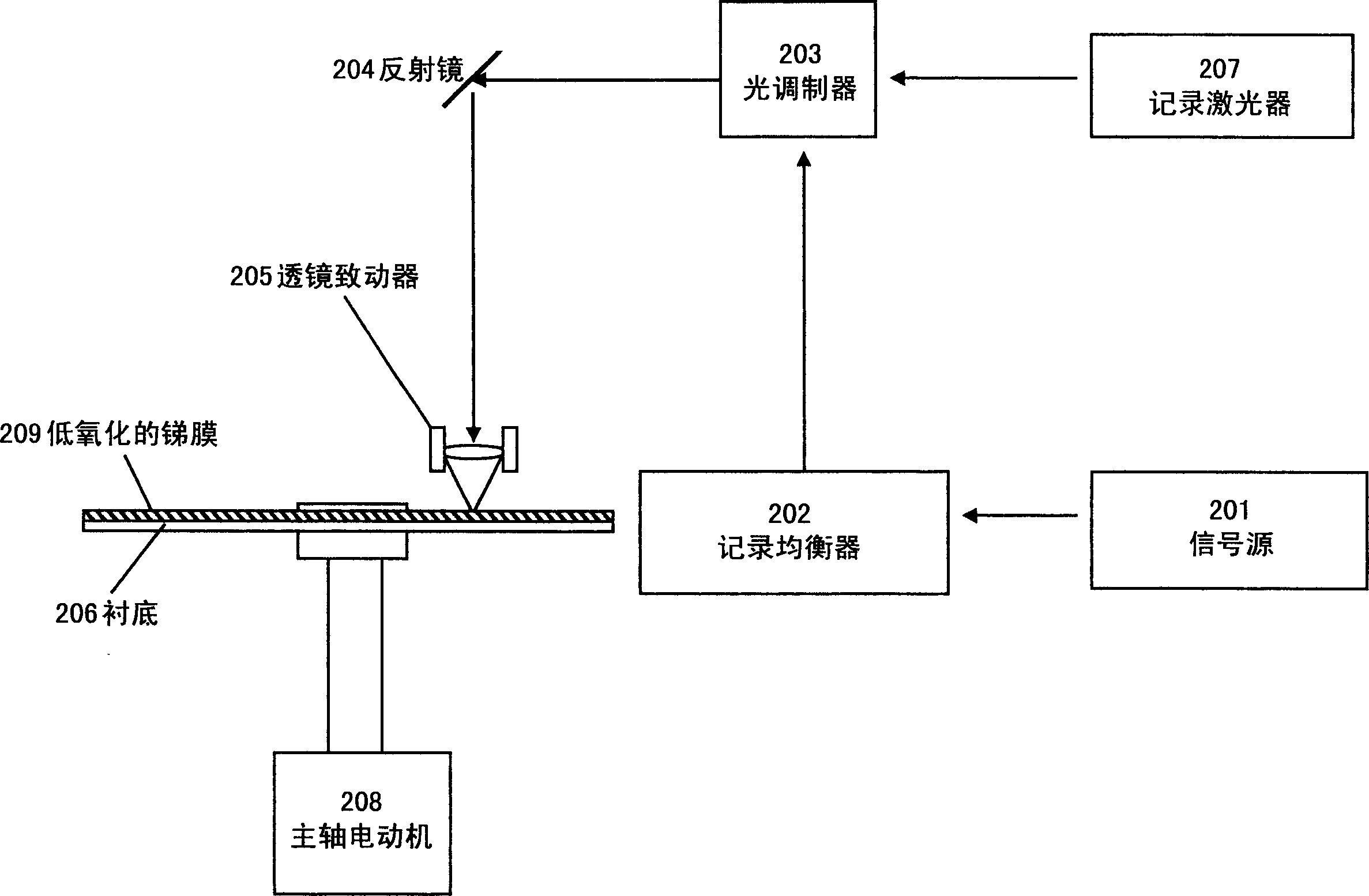

[0046] In the first embodiment, a low-oxidation film is formed as a heat-sensitive material layer 102 on a substrate 101 such as a ground glass substrate. After the DC magnetron sputtering equipment is equipped with an antimony target, and after the glass substrate 101 is fixed on the substrate holder, a cryopump is used to vacuum the inside of the chamber until 1×10 -4 High vacuum of Pa. While the vacuum is being exhausted, argon is introduced into the chamber until 0.10 Pa, and then, oxygen is introduced until the total pressure of 0.11 Pa. After that, while rotating the substrate 101, a direct current was applied to the antimony target to form a film, so that the film thickness of the antimony oxide became 80 nm.

[0047] In this embodiment, by introducing oxygen during the film formation, a low-oxidation antimony film can be formed on the substrate 101. However, a material having a composition of a low-oxidation antimony film can be used as a target material to perform sputter...

Embodiment 2

[0058] In Example 2, film formation, recording, and development were performed in the same manner as in Example 1. In this embodiment, when the antimony film is formed as a thermosensitive material under an oxygen atmosphere, at the same time, a tellurium target used as an additive is discharged to form a low-oxidation antimony film and a tellurium film. The tellurium content is adjusted by changing the tellurium input power during sputtering.

[0059] Adding tellurium to the thermosensitive material layer 102 containing antimony as a main component can reduce the surface roughness of the unexposed portion 104 during development. The surface roughness of the unexposed portion 104 is considered to be attributable to the low resistance of the portion that cannot maintain a stable amorphous state to the developer. In Example 2, it is conceivable that its solubility is less than that of Sb by adding 2 O 3 The solubility of tellurium can separate tellurium on the surface of the membran...

Embodiment 3

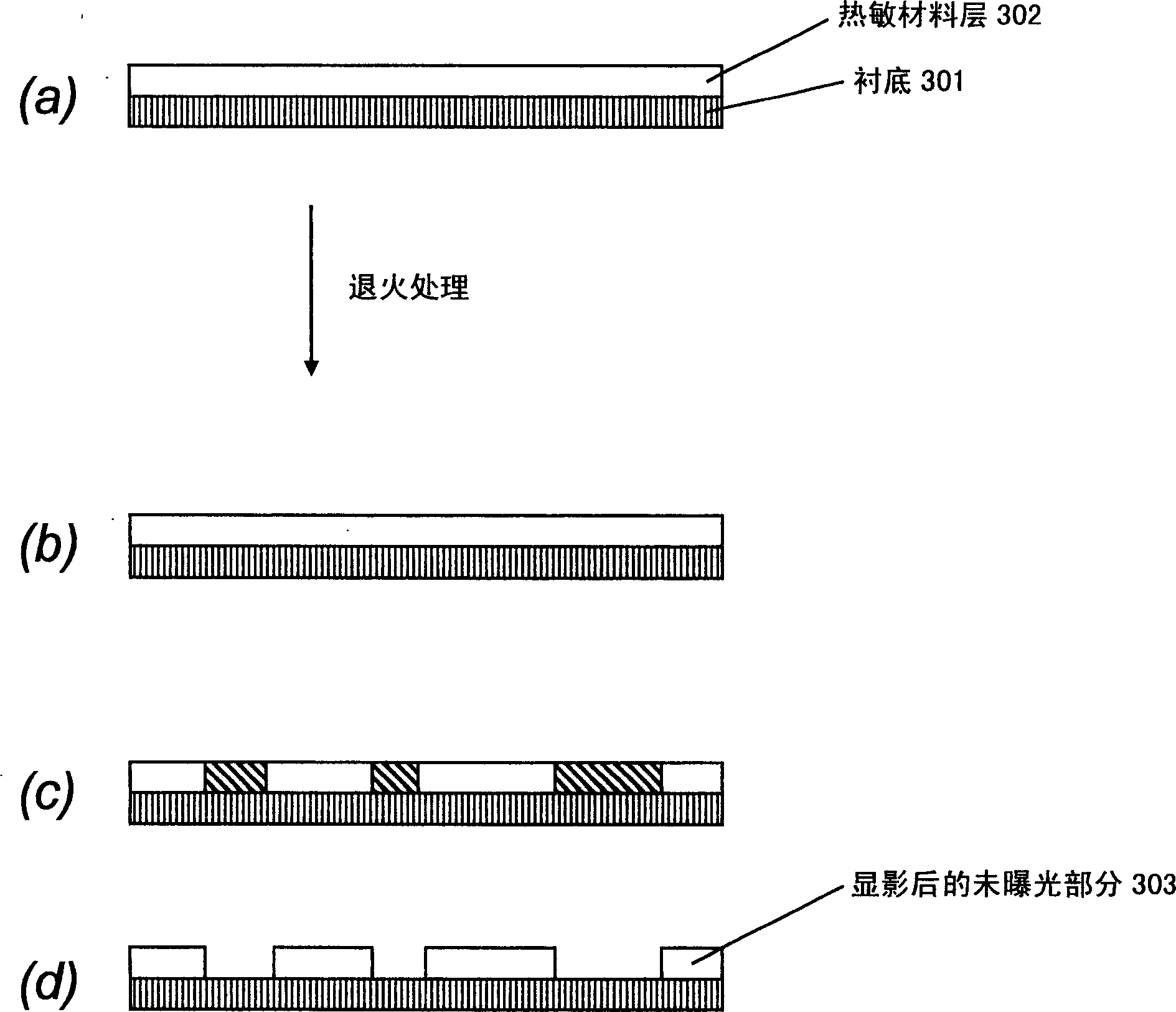

[0064] Will refer to image 3 To illustrate this embodiment. In the same manner as in Example 1, a low-oxidation antimony film as a heat-sensitive material layer 302 was formed on a substrate 301 including silicon by a magnetron sputtering process ( image 3 (a)). After that, in order to prevent the occurrence of defects in the unexposed part due to the development process, the thermosensitive material layer 302 was subjected to an annealing process ( image 3 (b)). Here, the annealing treatment is performed by placing the substrate 301 on which the heat-sensitive material layer 302 is formed in a cleaning furnace. By measuring the temperature of the thermosensitive material layer 302 and using the same recording device as in Example 1, a minute crystalline portion was formed in the thermosensitive material layer 302 ( image 3 (c)). Subsequently, the material thus obtained was soaked in a 2% tetramethylammonium hydroxide aqueous solution and then developed to remove the crystalli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com