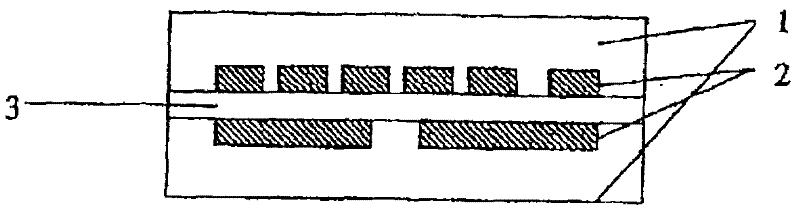

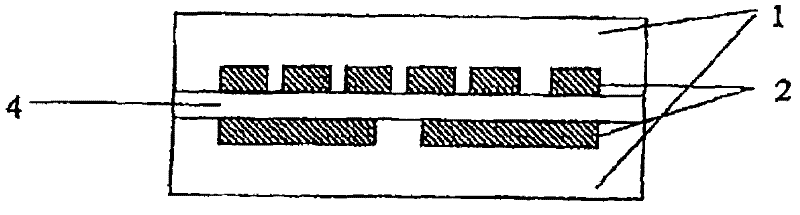

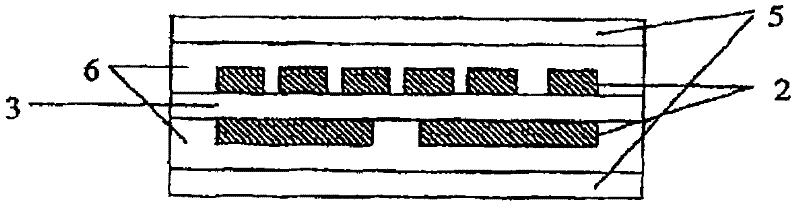

Double sided flexible printed circuit board for use hinge region

A circuit substrate, double-sided technology, applied in the direction of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of thinness, poor flexibility, increased thickness, hindering the high density of electronic circuits or electronic parts, etc., to achieve the suppression of conductors The effect of broken or broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples.

[0059] Processing copper foil circuit

[0060] A dry film is laminated on a double-sided copper-clad laminate made of a liquid crystal polymer film, and a circuit pattern is formed by UV (ultraviolet) exposure using a pattern film with a photoresist width of 100 μm and a circuit width of 100 μm. Next, copper foil etching was performed using a copper chloride etchant. The obtained double-sided conductor circuit board was checked with an optical microscope for peeling of circuits or residual copper between circuits.

[0061] Determination of thickness

[0062] According to JISC5016, the thickness of an insulating layer, a covering material, and a copper foil was measured using the film thickness tester (made by Mitutoyo Corporation, dial indicator 215-153).

[0063] Determination of initial resistance value

[0064] According to JISC5016, using a...

no. 1 Embodiment

[0070] A liquid crystal polymer film 280 (Beckstar (transliteration) manufactured by KURARAY Co., Ltd., heat distortion temperature 280°) with a thickness of 25 μm is used as an insulating layer, and rolled copper foil (BHY manufactured by Nippon Mining Materials Co., Ltd.) with a thickness of 18 μm is provided on both sides. -22B-T) double-sided copper-clad laminate, laminate dry film, and use a pattern film with a photoresist width of 100 μm and a circuit width of 100 μm, and use UV (ultraviolet) exposure to form a circuit pattern. Next, the copper foil was etched using a copper chloride etchant to fabricate a double-sided conductor circuit board W. Then, a liquid crystal polymer film 260 (Beckstar manufactured by KURARAY Co., Ltd., heat distortion temperature 260°) having a thickness of 25 μm was used as a covering material for the double-sided conductor circuit board W, and the above-mentioned rolled copper foil having a thickness of 18 μm was prepared on one side. The sin...

no. 2 Embodiment

[0074] Except for using a liquid crystal polymer film 260 with a thickness of 50 μm as the cover material, a double-sided flexible circuit board was produced in the same manner as in the first embodiment, and the same experiment was carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com