Light source device

A technology of light source device and lamp holder, which is applied in the direction of coupling device, lighting device, light source fixing, etc., can solve the problem of unsuitable lamp holder seat and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

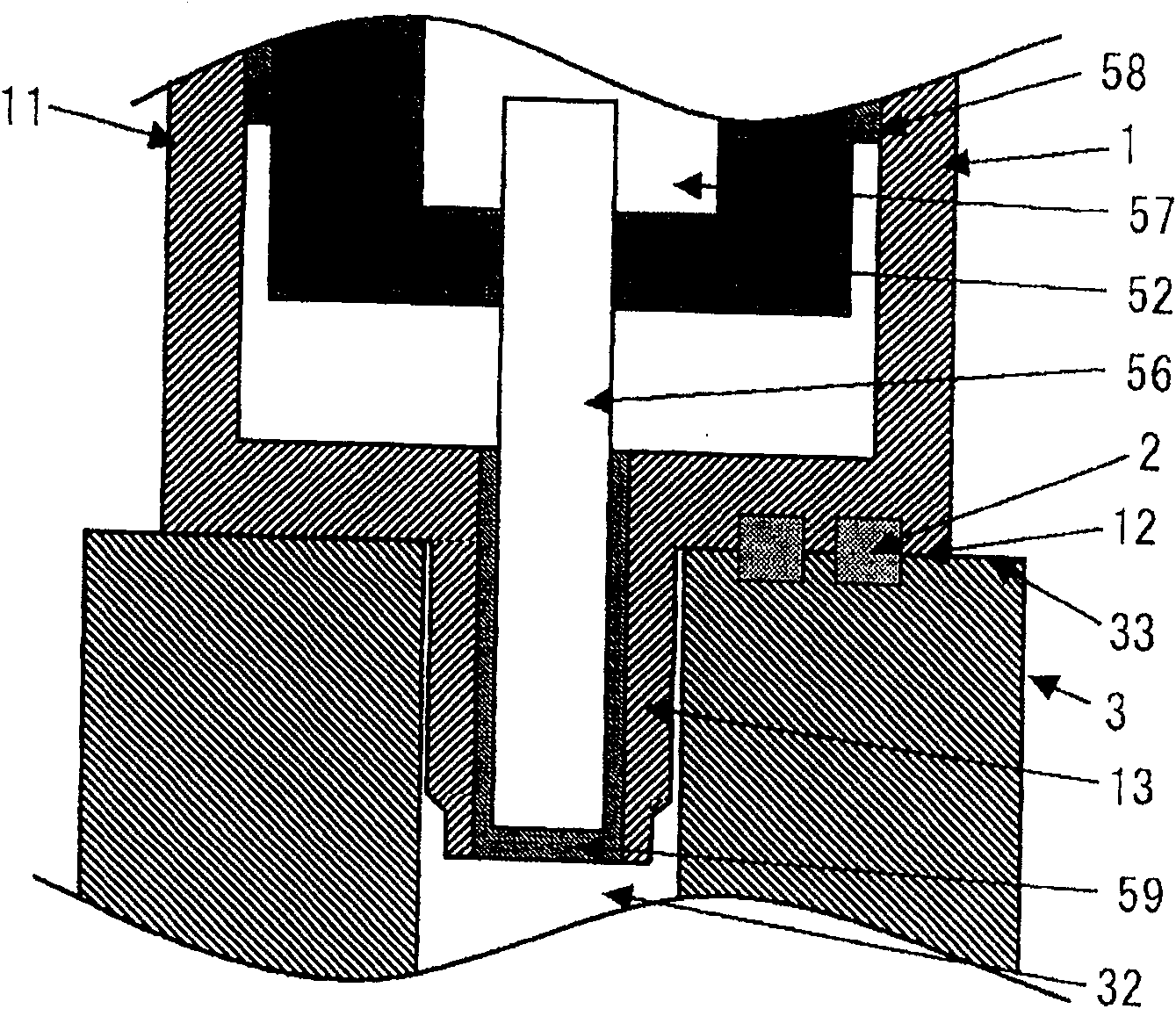

[0026] Below, refer to Figure 1 to Figure 7 , to describe in detail the preferred modes for carrying out the present invention.

[0027] 【Example】

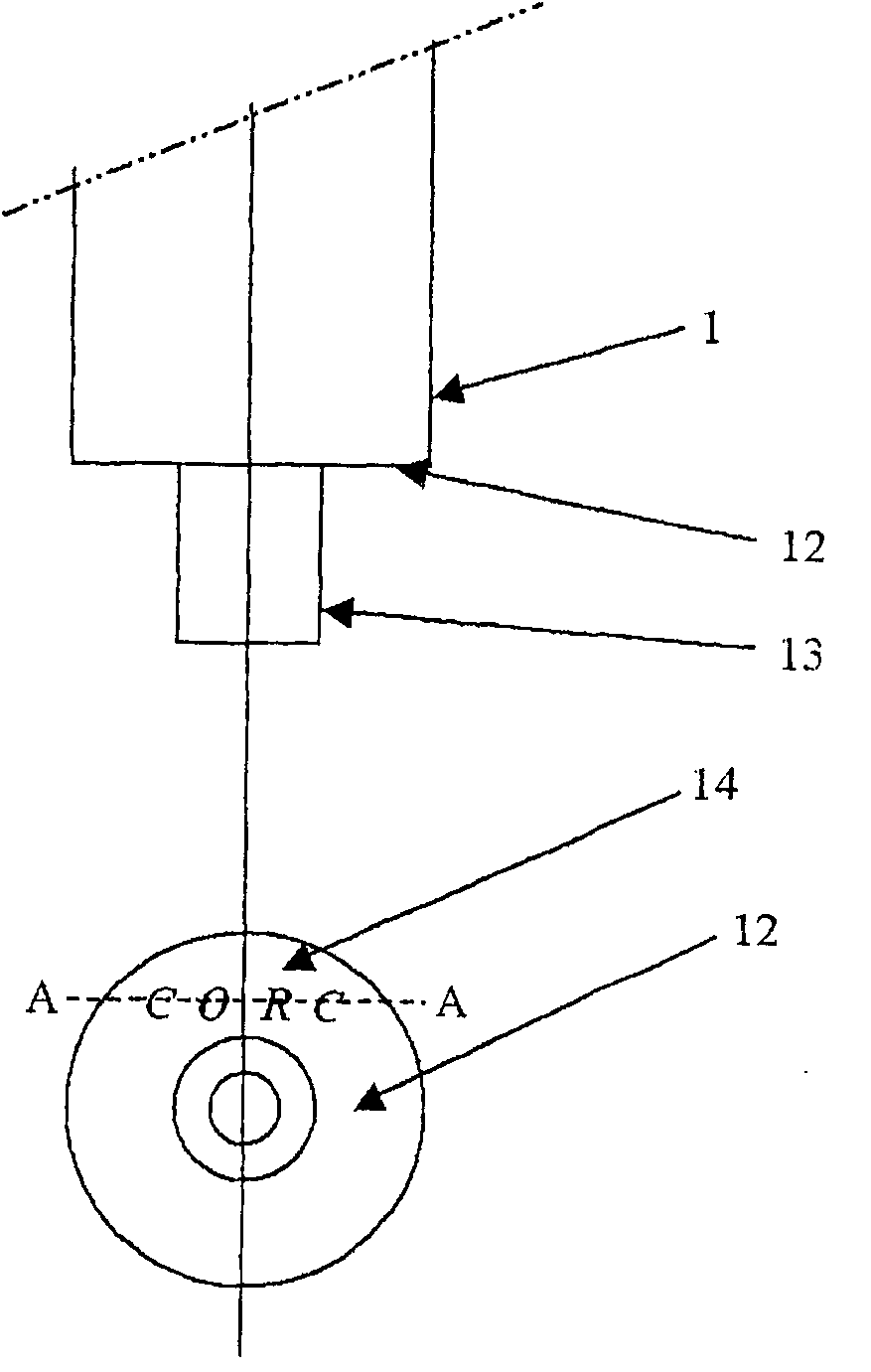

[0028] An embodiment of the present invention is a light source device in which a positive mark is engraved on the end surface of a discharge lamp cap, and a concave portion is engraved with a reverse mark that is mirror-symmetrical to the positive mark on the end face of the cap holder that holds the cap. , insert a stopper imitating the positive mark between the two concave parts.

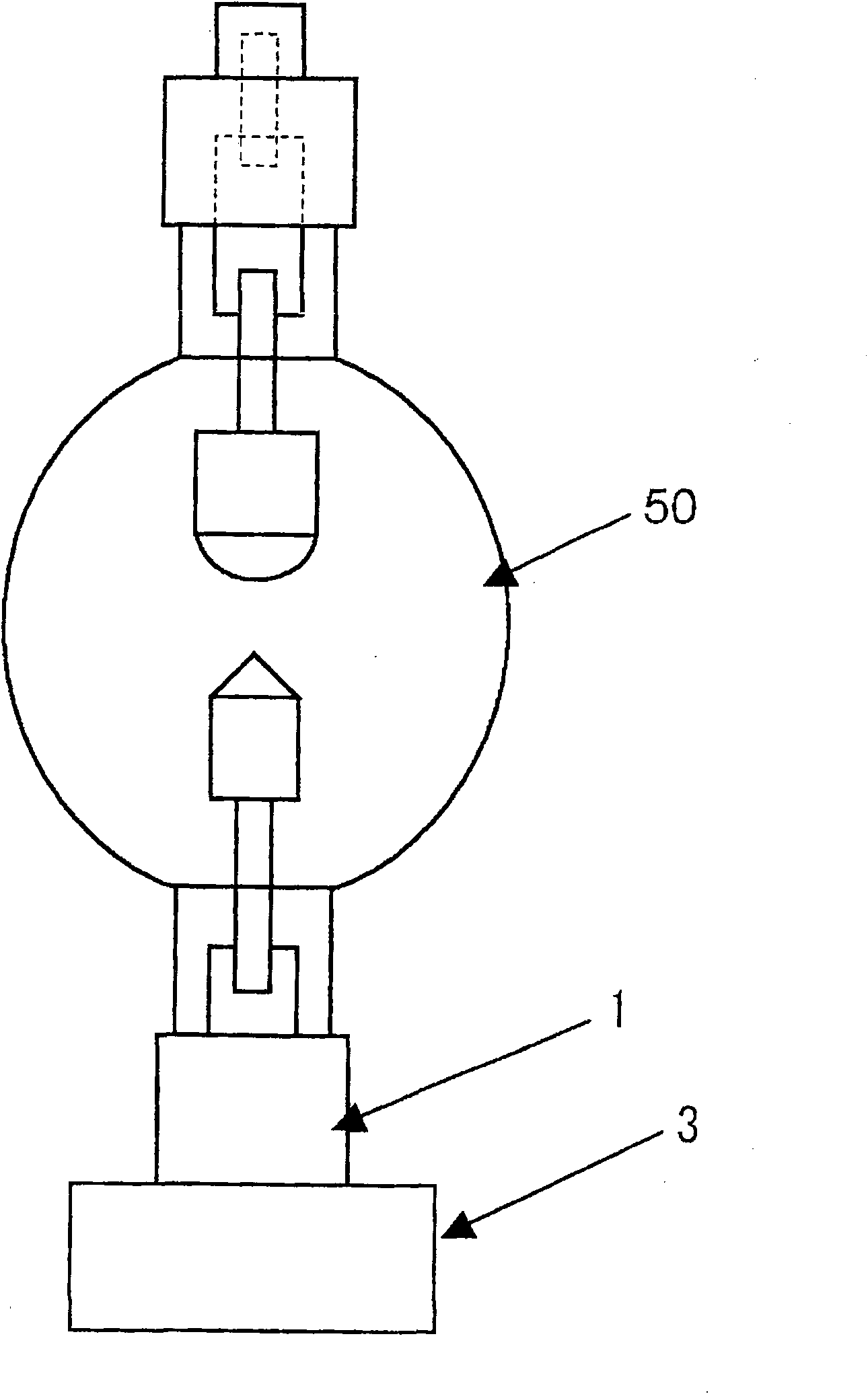

[0029] figure 1 It is an external view of a state where a discharge lamp base structure is attached to a base holder of a light source device in an embodiment of the present invention. figure 1 Among them, the base structure 1 is a metal base having a large-diameter cylindrical base portion, a small-diameter base protrusion, and a surface connecting the base portion and the base protrusion. The base holder 3 is a member that holds the lamp via...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com