Optical film, multilayer optical film including same, and method for producing optical film

A manufacturing method and optical film technology, which is applied in the field of optical films, can solve problems such as delay in the thickness direction, and achieve the effect of easy in-plane delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

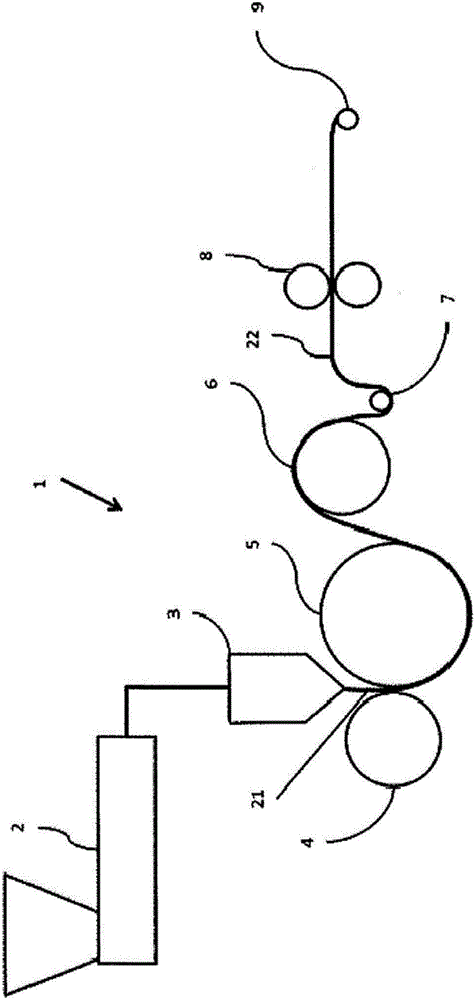

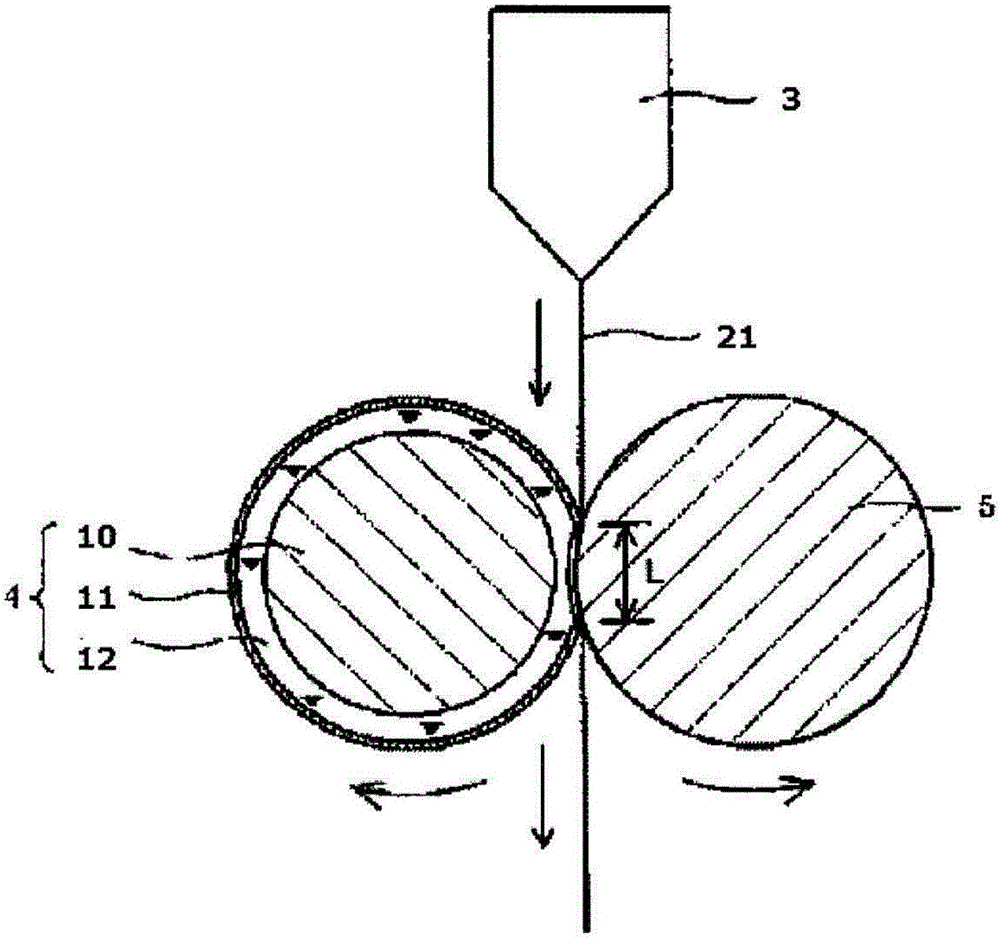

[0132] Using IUPIRON H4000, which is bisphenol A polycarbonate with a viscosity average molecular weight of 14,000 to 17,000, by melt extrusion method, according to figure 1 , A transparent polycarbonate film with a thickness of 100 μm was molded at a molding temperature of 270° C. through a T die, and supplied to a metal elastic roller with a diameter of 300 mm and a metal roller with a diameter of 400 mm at about 260° C. It was cooled between rolls at 135° C. to obtain a film with a thickness of 100 μm. However, at this time, the linear pressure received by the molten polycarbonate resin from the central portion of the two cooling rolls was 15 kgf / cm, and the pulling speed was 14.5 m / min. Moreover, since the heat distortion temperature (Th) of polycarbonate resin was 124 degreeC, the difference with the surface temperature (Tr) of a roll was 11 degreeC.

Embodiment 2

[0183] Mix 28 parts by weight of Mitsubishi Engineering Plastics Co., Ltd. product polyphenylene ether resin (PPE) trade name: PX100L and 72 parts weight PS Japan Co., Ltd. product general-purpose polystyrene (GPPS) product name: HH105 as a positive birefringence material A total of 100 parts by weight was used to produce a film having a thickness of 200 μm at a setting of 290° C. using a film production apparatus equipped with a T-die. The obtained film was heated to 125°C and uniaxially stretched 2.3 times to obtain a film (film 2). The obtained sample and the film (film 1) shown in the reference example mentioned later were laminated|stacked using an adhesive agent. Table 2 shows the evaluation results of the optical properties.

[0184] [reference example]

[0185] In the same manner as in Example 1, a film (film 1) having a thickness of 100 μm was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| hazing | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com