Composition and organic optoelectronic element and its manufacturing method

A technology for optoelectronic components and manufacturing methods, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, and electric-solid-state devices, etc., can solve problems such as large room for improvement, and achieve the effect of improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0194] Fabrication of the charge transport layer

[0195] Two silicon substrates and one quartz substrate cut into about 2 cm square were ultrasonically cleaned with neutral detergent, acetone, and isopropanol, and then boiled and washed in isopropanol, and then treated with ozone to remove attachments. The substrates were respectively placed in a vacuum evaporation machine and vacuumed to a pressure of 10 -4 Pa or below, then use α-NPD and fluoropolymer A at a volume ratio of α-NPD and fluoropolymer A of 45:55, perform resistance heating in a vacuum evaporation machine, and perform co-evaporation, Thus, a charge transport layer having a thickness of about 100 nm was produced on each substrate. The total vapor deposition rate of the two materials was set to 0.2 nm / s. The surface roughness of the obtained charge transport layer was 0.33 nm.

[0196] Fabrication of elements for conductivity evaluation

[0197]A glass substrate on which a strip-shaped ITO (indium tin oxide) ...

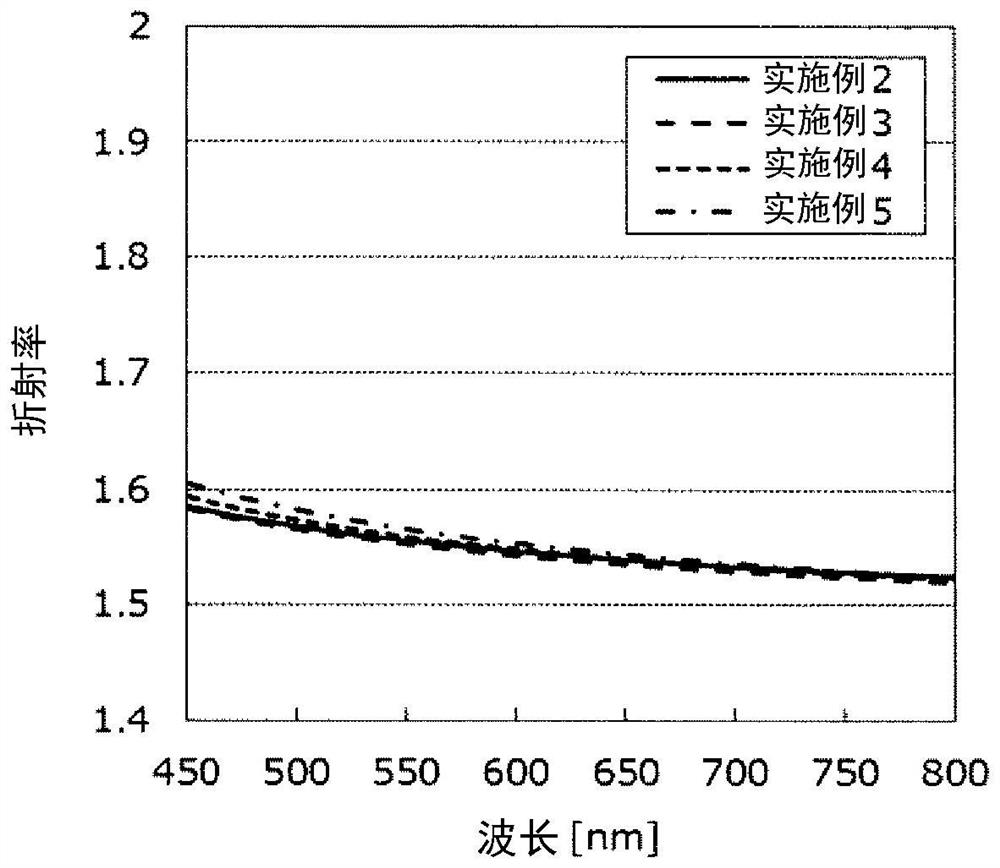

Embodiment 2~9

[0199] Except having used fluoropolymers B to J (except for D) instead of fluoropolymer A, it carried out similarly to Example 1, and produced the charge transport layer and the element for electroconductivity evaluation.

[0200] In addition, in Table 1, the name of the polymer used in each Example is described.

Embodiment 10

[0202] Except having used the fluorine-containing polymer K instead of the fluorine-containing polymer A, it carried out similarly to Example 1, and produced the charge transport layer and the element for conductivity evaluation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

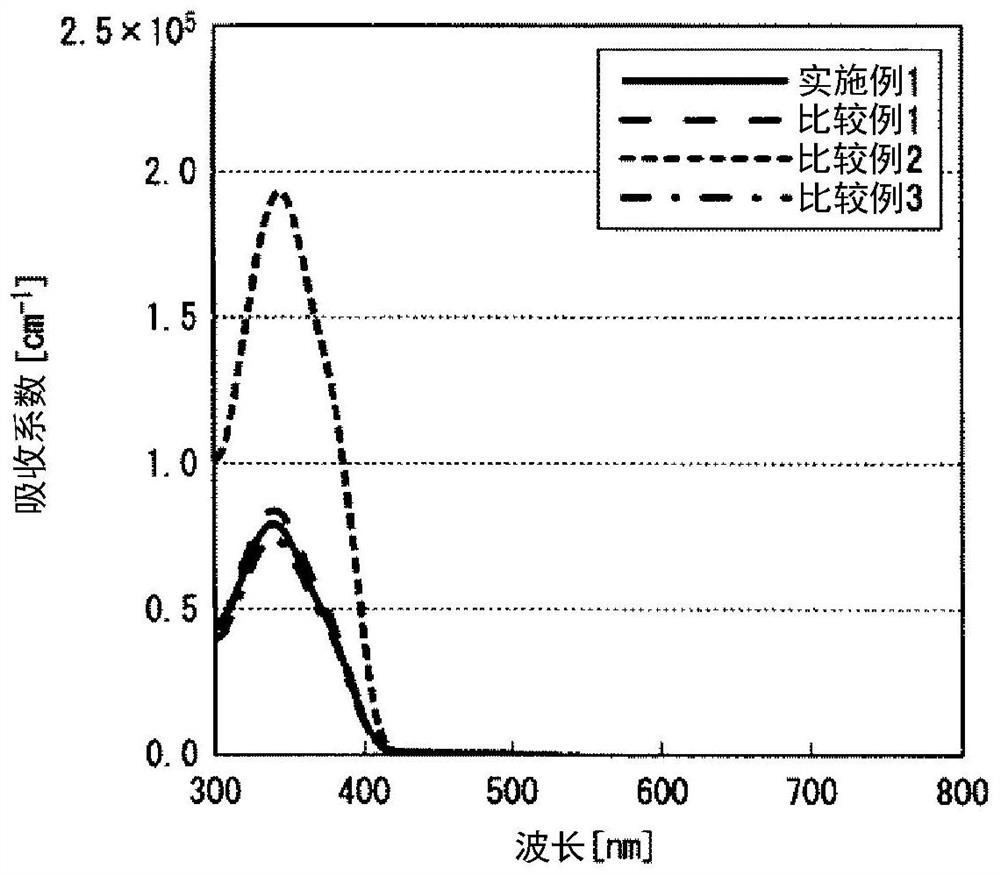

| absorption coefficient | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com