Electrical connector with suction member

A technology of electrical connectors and connectors, which is applied in the direction of two-component connection devices, connections, fixed connections, etc., can solve the problem of not being able to fully prevent the bending and deformation of the shell, and achieve a low-cost and easy-to-manufacture solution that prevents poor soldering connections Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

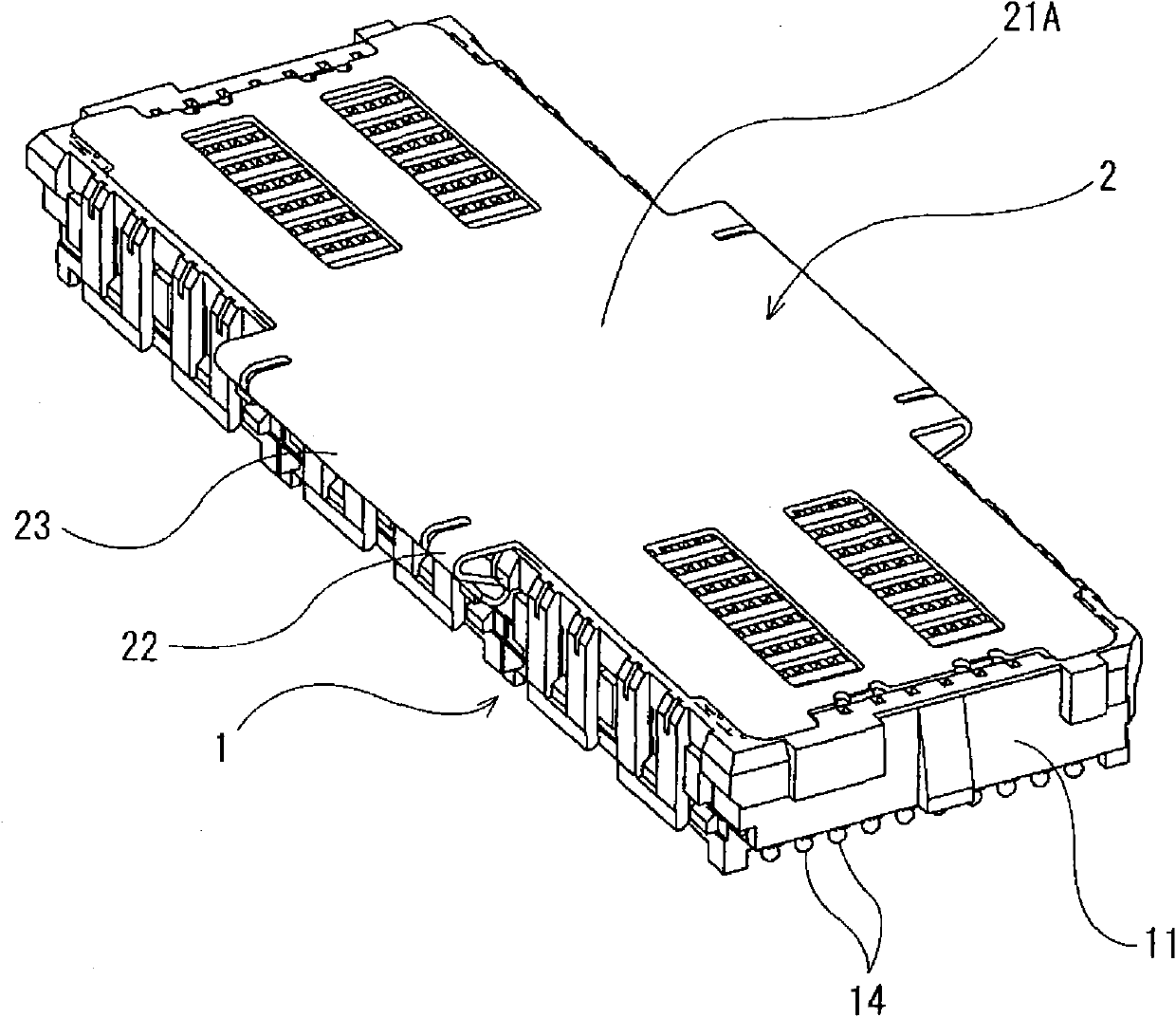

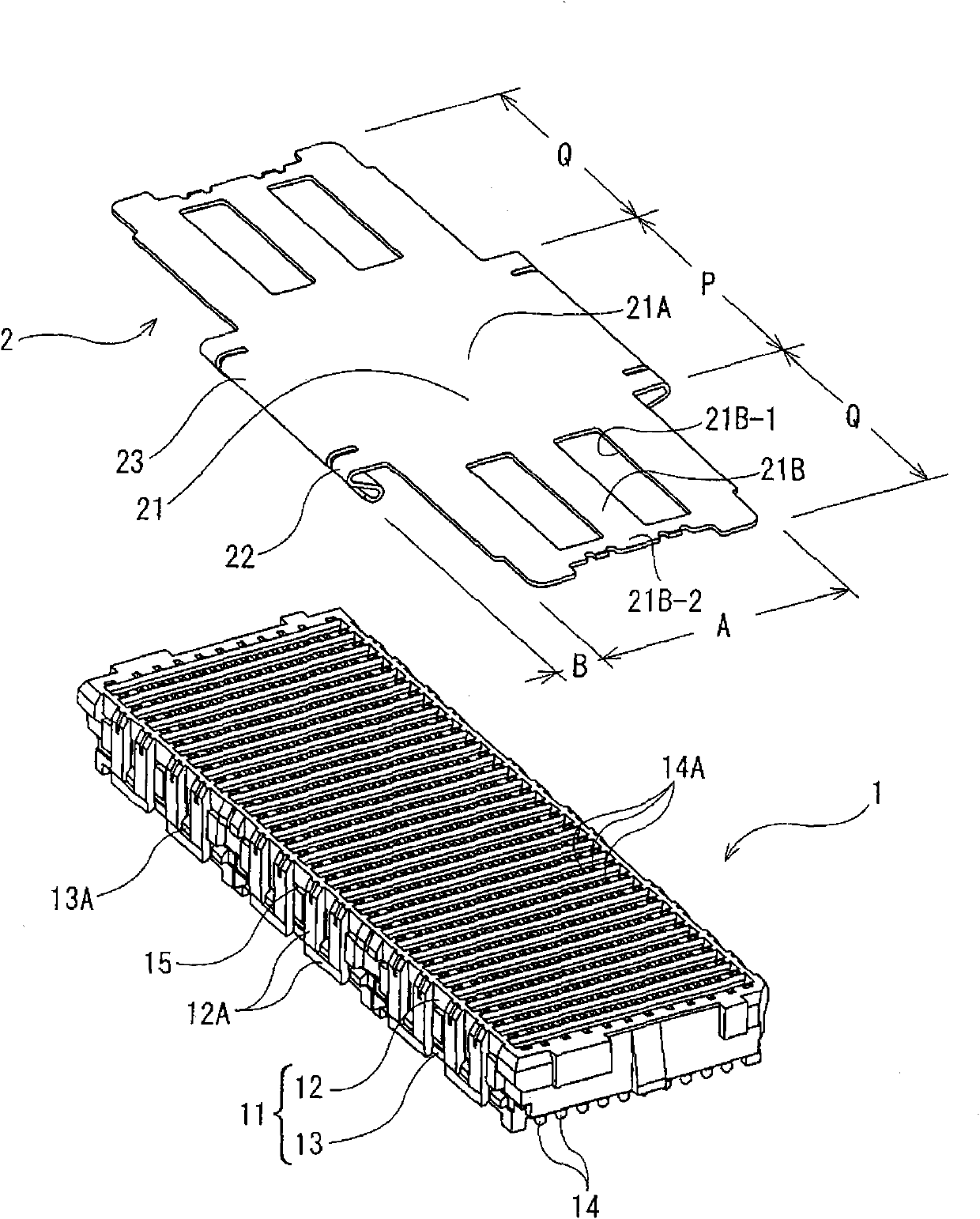

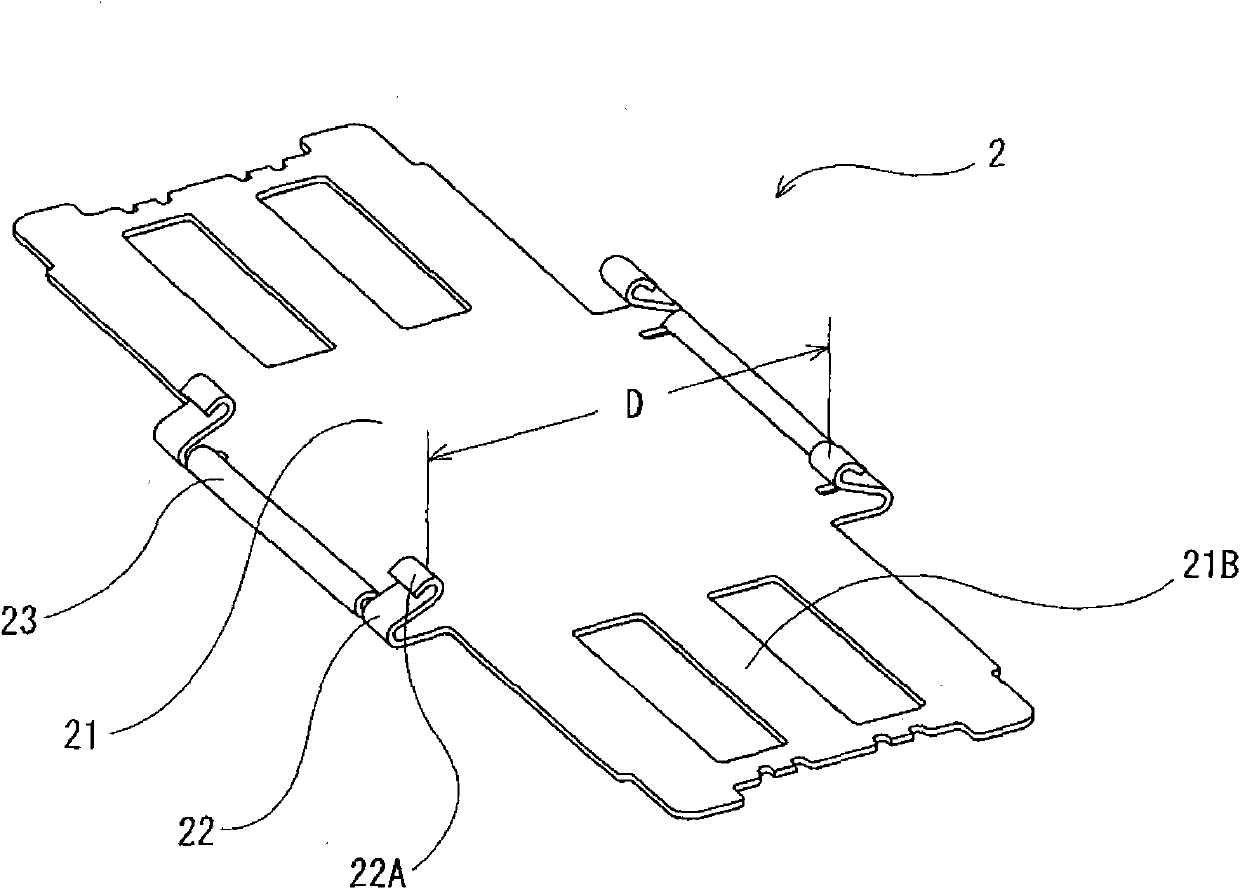

[0032] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0033] The electrical connector of this embodiment is such as figure 1 As shown, before mounting on the circuit board by soldering, the suction member 2 is mounted on the upper surface of the connector 1 in order to suction and transport to the mounting position by the suction mechanism.

[0034]The connector 1 holds terminals (not shown) on a housing 11 composed of an upper housing member 12 and a lower housing member 13, and protrudes from the lower surface of the lower housing member 13 for installation by soldering connection. Solder balls 14 are provided on the connecting parts of the terminals. The above-mentioned upper casing part 12 is provided with a locking leg 12A extending downward in a U-shape and having elasticity on its side in the longitudinal direction. Instead, the two housing parts 12 and 13 are combined. The locking is formed by the upper edge of the U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com