Additive used in a membrane-separation activated sludge process

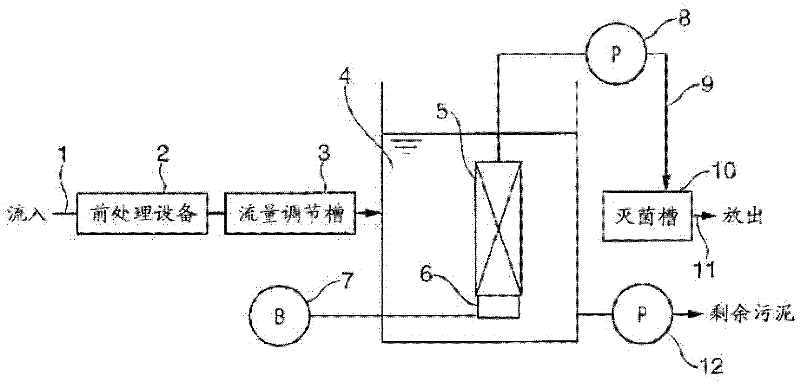

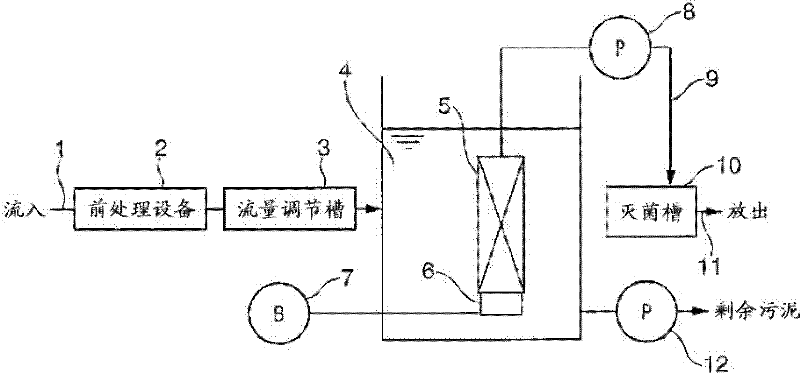

An activated sludge method and activated sludge technology, applied in the field of additives, can solve the problems of limited filtration period, reduced filtration efficiency, and reduced effective membrane area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] An agar plate medium containing 0.15% of a phosphorus component, 0.04% of a nitrogen component, and 0.001% of a Mg component was prepared. Then, polygalacturonic acid (manufactured by Sigma-Aldrich) was dispersed in the agar solution, and laminated on the above-mentioned medium. Thus, an agar plate medium using polygalacturonic acid as the sole carbon source was prepared.

[0084] Activated sludge, soil, and lake marshes were similarly smeared and inoculated on this medium, and cultured at 28°C for 72 hours to form colonies of molds on an agar plate. The colonies contain at least the fungi of the genus Penicillium and the genus Phalaenopsis.

[0085] Use a platinum inoculation loop to aseptically inoculate the mold produced on the agar plate into 20 mL of a liquid medium with a concentration of 1 g / L polygalacturonic acid as the sole carbon source, and the liquid medium contains a phosphorus component of 0.15 %, 0.04% of the nitrogen component and 0.001% of the Mg com...

Embodiment 2

[0091] An agar plate medium containing 0.15% of a phosphorus component, 0.04% of a nitrogen component, 0.001% of a Mg component, and 1 g / L of xanthan gum (manufactured by Sigma-Aldrich) was prepared. In this way, an agar plate medium using xanthan gum as the sole carbon source was prepared.

[0092]Activated sludge, soil, and lake marshes were similarly smeared and inoculated on this medium, and cultured at 28° C. for 72 hours to form bacterial colonies on an agar plate. The colony contains at least Microbacterium, Paleobacterium, Pseudoxanthomonas, Fluviicola sp., Geobacter, Paenibacillus, and Cohnella species, Brevundimonas species, Hydrogenophages species, Sphingomonas species, Neosphingobacterium species, Sphingomonas species, Sphingosine Bacillus species, Bacteroidetes species, Xanthomonas species, De Vossia species, Stenobacteria species, α-Proteobacteria species and Flexibacteriaceae species.

[0093] The bacterial colony produced on the agar plate was aseptically ino...

Embodiment 3

[0098] An agar plate medium containing 0.15% of a phosphorus component, 0.04% of a nitrogen component, 0.001% of a Mg component, and 1 g / L of hyaluronic acid was prepared. Thus, an agar plate medium using hyaluronic acid (manufactured by Sigma-Aldrich) as a sole carbon source was prepared.

[0099] Activated sludge, soil, and lake marshes were similarly smeared and inoculated on this medium, and cultured at 28° C. for 72 hours to form bacterial colonies on an agar plate. In this colony at least contain Fluviicola sp., Geobacter sp., Paenibacillus sp., Kernella sp., Brevundimonas sp., Hydrophage sp., Sphingosine Monas species, Microbacterium species and Paleobacterium species.

[0100] Bacterial colonies produced on the agar plate were aseptically inoculated with a platinum inoculation loop in 20 mL of a liquid medium with a concentration of 1 g / L of hyaluronic acid as the sole carbon source. The liquid medium contained 0.15% phosphorus and nitrogen 0.04% and 0.001% of the Mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com