Spline hub for clutch and manufacturing method thereof

A manufacturing method and technology of spline wheels, which are applied in clutches, friction clutches, mechanical drive clutches, etc., can solve problems such as rising production costs, and achieve low-cost and easy-to-manufacture, shortened manufacturing process and time, sufficient strength and wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Mix C: 3.5%, Si: 1.6%, Mn: 0.3%, P: 0.01%, S: 0.01%, Cu: 0.2%, and Fe as the rest in a weight ratio, and put all the raw materials into a medium frequency induction resistance furnace The nodular cast iron stock solution is smelted, and the temperature of the nodular cast iron stock solution (stock solution) taken out from the furnace is 1503°C.

[0073] The nodular cast iron stock solution taken out of the furnace after smelting is subjected to spheroidization treatment and inoculation treatment. As a spheroidizer, 1.0% of the mass of the stock solution is added with a rare earth ferrosilicon-magnesium alloy (FeSiMg6RE1), as an inoculant. Barium ferrosilicon alloy (FeSi72Ba2) equivalent to 0.15% of the mass of the stock solution. As a result, it was confirmed that the components (wt%) of the melt were C:3.5, Si:2.2, Mn:0.3, P:0.01, S:0.015, Cu:0.2, and Mg:0.045.

[0074] The melt that has been spheroidized and inoculated is injected into the pre-prepared wet sand mold...

Embodiment 2

[0078] C: 3.6%, Si: 1.5%, Mn: 0.35%, P: 0.007%, S: 0.012%, Cu: 0.25% and the rest of Fe are mixed and melted, then taken out at 1520°C, and put into the original solution for melting 1.1% FeSiMg6RE1 of liquid mass and 0.15% FeSi72Ba2 of raw liquid mass. The composition (wt %) of the melt subjected to the spheroidization treatment and the inoculation treatment was C: 3.6, Si: 2.2, Mn: 0.4, P: 0.007, S: 0.017, Cu: 0.25, and Mg: 0.048.

[0079] Thereafter, the molten sand film was injected into the wet sand film at a temperature of 1410° C. for 7 minutes and then cooled. After machining the obtained wheel hub semi-finished product, carry out austempering treatment. At this time, heat the hub semi-finished product to 910° C., keep it for two hours, and then put it into the nitrate solution at 340° C. for 1.5 hours. Thereafter, after cooling to room temperature in the air, fine grinding and polishing are performed.

Embodiment 3

[0081]C: 3.8%, Si: 1.8%, Mn: 0.4%, P: 0.009%, S: 0.009%, Cu: 0.3%, and the rest of Fe are mixed and melted, taken out at 1515°C, and put into the original solution to melt 1.1% FeSiMg6RE1 liquid mass and 0.15% FeSi72Ba2 liquid mass. The composition (wt %) of the melt subjected to the spheroidization treatment and the inoculation treatment was C:3.8, Si:2.3, Mn:0.4, P:0.01, S:0.01, Cu:0.3, Mg:0.05.

[0082] Thereafter, the molten sand film was injected into the wet sand film at a temperature of 1402° C. for 7 minutes and then cooled. After machining the obtained wheel hub semi-finished product, carry out austempering treatment. At this time, heat the hub semi-finished product to 920° C., keep it for two hours, and then put it into the nitrate solution at 360° C. for 1.5 hours. Thereafter, after cooling to room temperature in the air, fine grinding and polishing are performed.

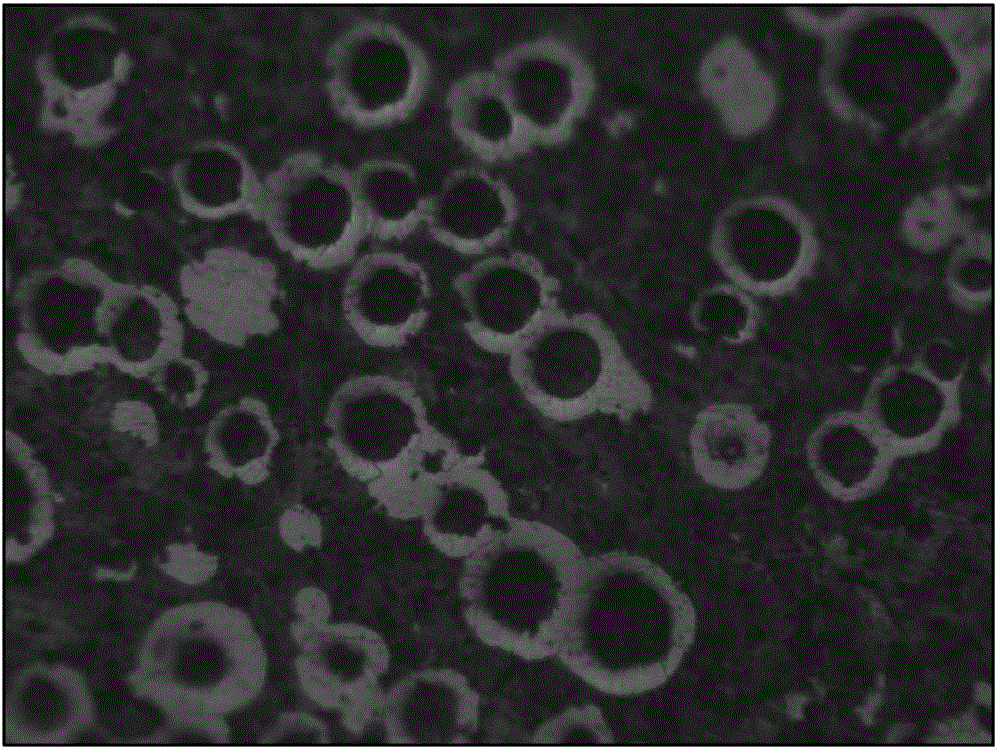

[0083] figure 1 For taking the photograph of the internal organization of above-mentioned embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com