Method for reducing warping of glass substrate caused by chemically toughening treatment, and method for producing chemically toughened glass substrate

A glass substrate, strengthening treatment technology, applied in the direction of gaseous chemical plating, coating, metal material coating process, etc., can solve problems such as damage to the flatness of float glass, achieve excellent productivity and cost, cost reduction, manufacturing cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

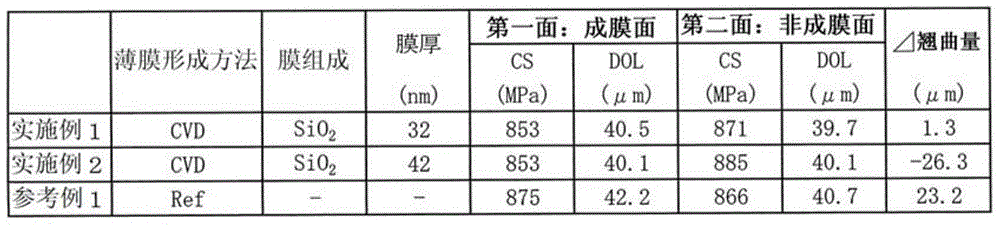

[0097] Hereinafter, examples of the present invention will be specifically described, but the present invention is not limited to these examples.

[0098] (1) Manufacture of float glass

[0099] A glass material having the following composition was made into a plate with a thickness of 0.8 mm by the float method, and cut into 50×50 mm to produce a float plate glass.

[0100] (Glass material A) Contains 64.3% SiO in mol% 2 , 8.0% Al 2 o 3 , 12.5% Na 2 O, 4.0% K 2 O, 10.5% MgO, 0.1% CaO, 0.1% SrO, 0.1% BaO and 0.5% ZrO 2 the glass

[0101] (2) Production of glass substrates for chemical strengthening

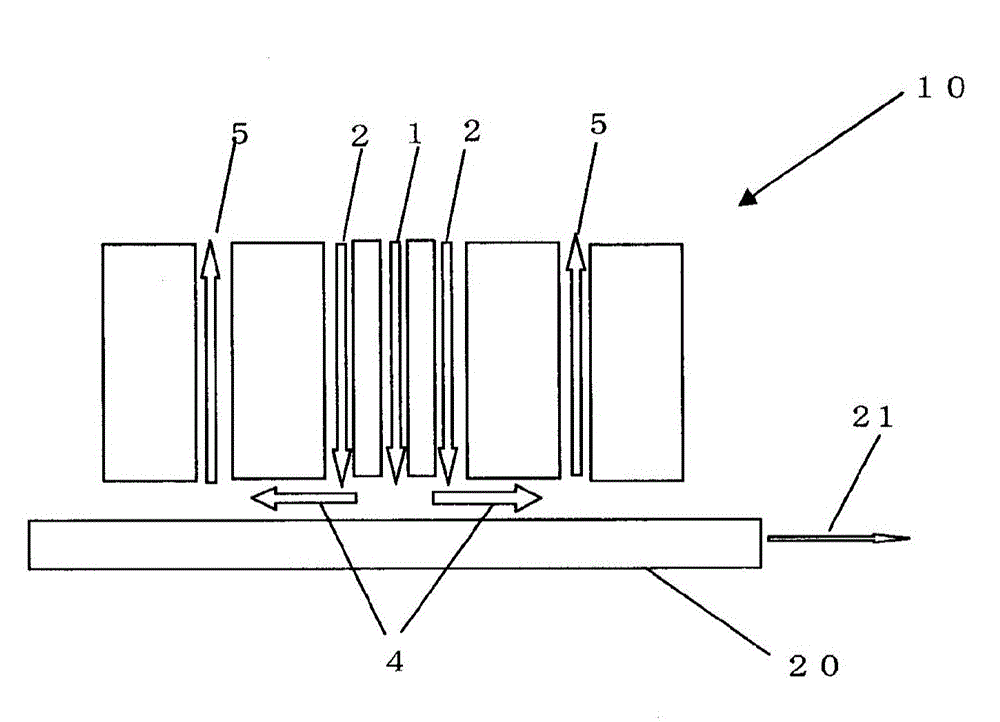

[0102] Using the injector 10 used in the atmospheric pressure CVD method, according to figure 1 In the schematic diagram shown, the surface of the float flat glass produced in (1) is supplied with monosilane (SiH 4 ), oxygen (O 2 ) gas, so that monosilane and oxygen react on the surface of the glass substrate to form SiO 2 film on the glass substrate.

[0103] That i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface pressure | aaaaa | aaaaa |

| surface pressure | aaaaa | aaaaa |

| surface pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com