Roll outer layer material for rolling, and composite roll for rolling

A technology of outer layer material and composite roll, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of easy segregation, segregation, easy agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 〕

[0127] The rolling roll outer layer material of the present invention is centrifugally cast. The "centrifugally cast rolling roll outer layer material" as used herein refers to a rolling roll outer layer material in a state produced by a centrifugal casting method conventionally used as a rolling roll manufacturing method. The rolling roll outer layer material produced by the centrifugal casting method ("centrifugal casting" rolling roll outer layer material) can be clearly distinguished as a "product" from the rolling roll material manufactured by a conventional manufacturing method other than this, In addition, it is impractical to determine the "centrifugal casting" roll outer layer material with structure and performance, requiring a lot of labor.

[0128] The roll outer layer material for rolling of the present invention is made of a W-Co-based alloy, and has a composition in which the W content decreases radially from the outer peripheral side of the roll to the inner pe...

no. 2 Embodiment approach 〕

[0164] The rolling roll outer layer material of the present invention is centrifugally cast. The "centrifugally cast rolling roll outer layer material" as used herein refers to a rolling roll outer layer material in a state produced by a centrifugal casting method conventionally used as a rolling rolling roll manufacturing method. Rolling roll outer layer materials produced by centrifugal casting ("centrifugal casting" rolling roll outer layer materials) and rolling rolls manufactured by conventional manufacturing methods other than this method can be classified as "products". It is impractical to make a clear distinction between different forms, and to determine the outer layer material of the "centrifugal casting" rolling roll with structure and performance, which requires a lot of labor.

[0165] The roll outer layer material for rolling of the present invention is made of a W-Co-based alloy, has a gradient composition in which the W content decreases from the outer periphe...

Embodiment 1

[0210] First, examples in the first embodiment described above will be described.

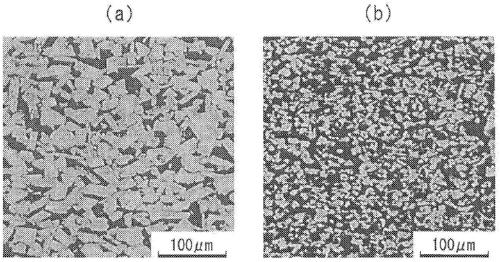

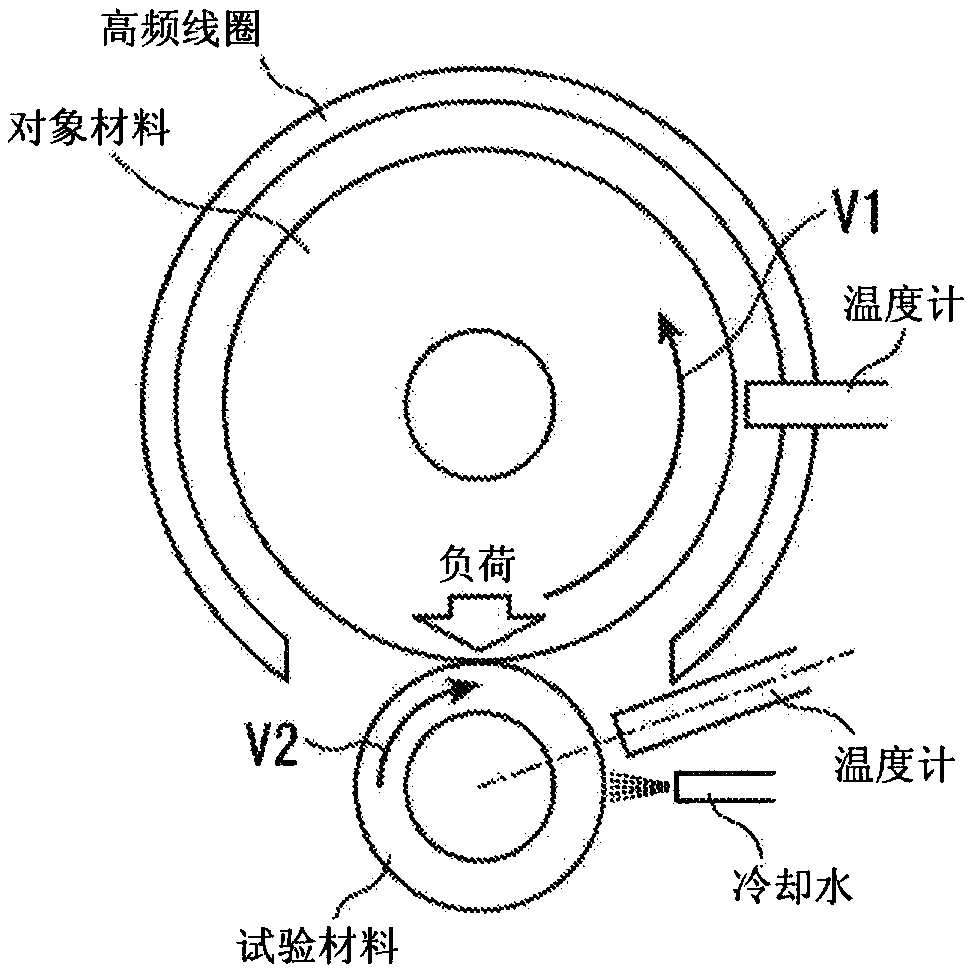

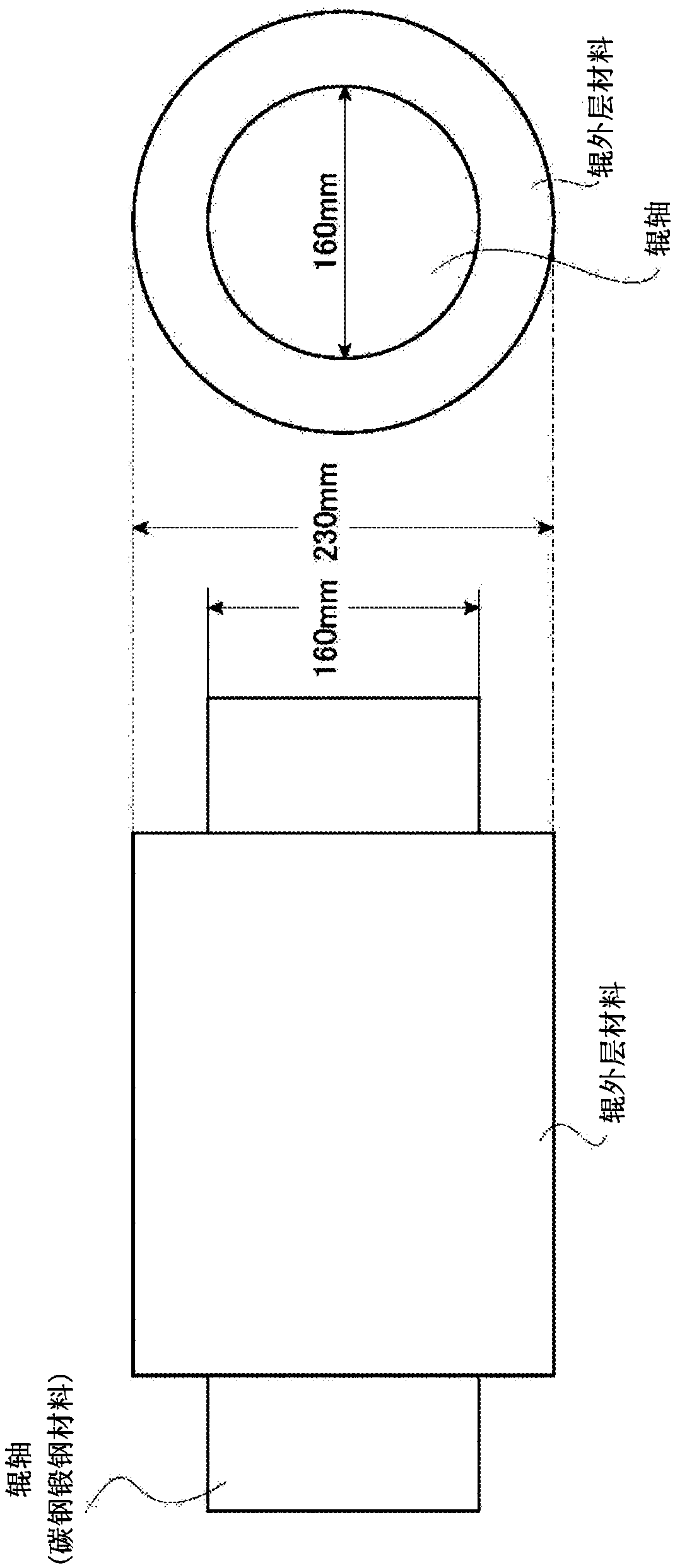

[0211] The molten metal of the composition shown in Table 1 was melted in a high-frequency induction furnace, and cast into a sleeve-shaped roller outer layer material (outer diameter: Radial wall thickness: 55mm). It should be noted that the casting temperature is 1450-1550°C, and the centrifugal force is 140-220G in multiples of gravity. In some test materials (molten metal No. S), since significant carbide segregation toward the inner surface occurred, it was set to 60G for the purpose of reducing the segregation. After casting, reheat to 1050-1200°C and keep for 10h, then repeat the quenching treatment of cooling to below 100°C and the tempering treatment of cooling after heating and keeping at 400-560°C once or twice. Thereby, the hardness from the outer surface of a test material to the position of 5 mm along the thickness direction was adjusted to about 85-100 HS. It should be noted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com