Sealing cover for high-voltage cable connector

A high-voltage cable and connector technology, applied in the electrical field, can solve the problems of short distance, inability to install transformers, creepage, etc., to maintain waterproof and insulating properties, prevent creepage, and increase surface distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

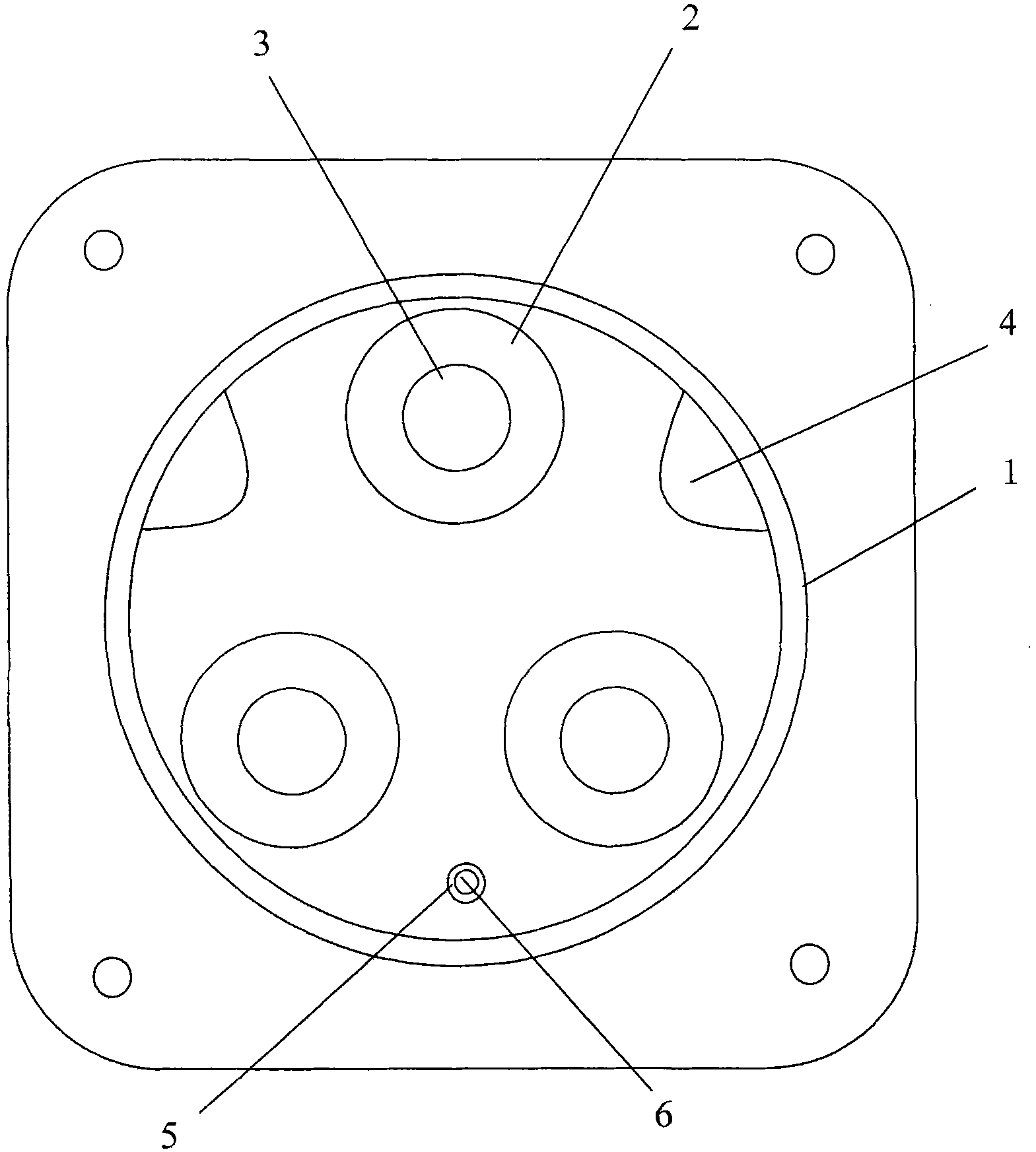

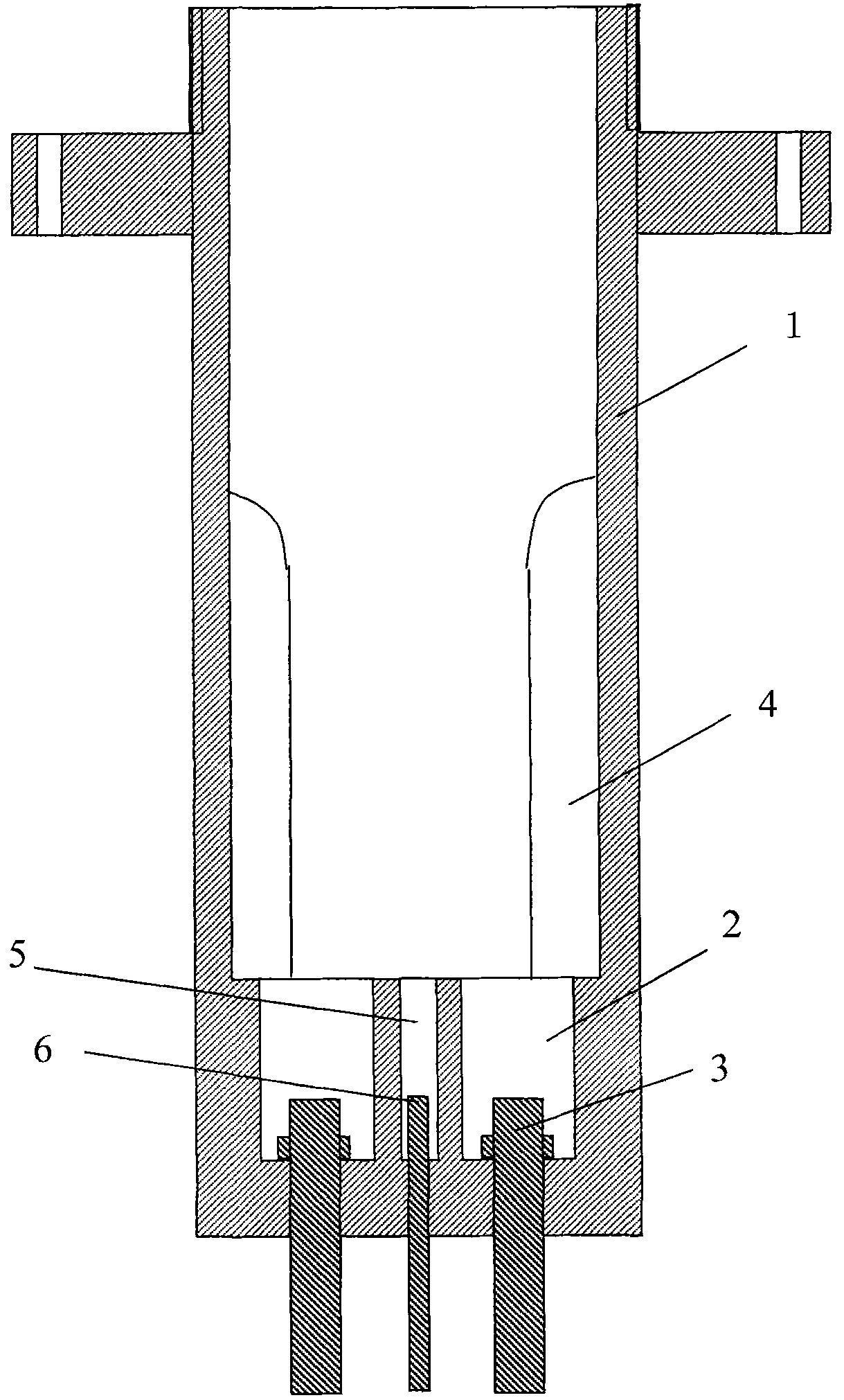

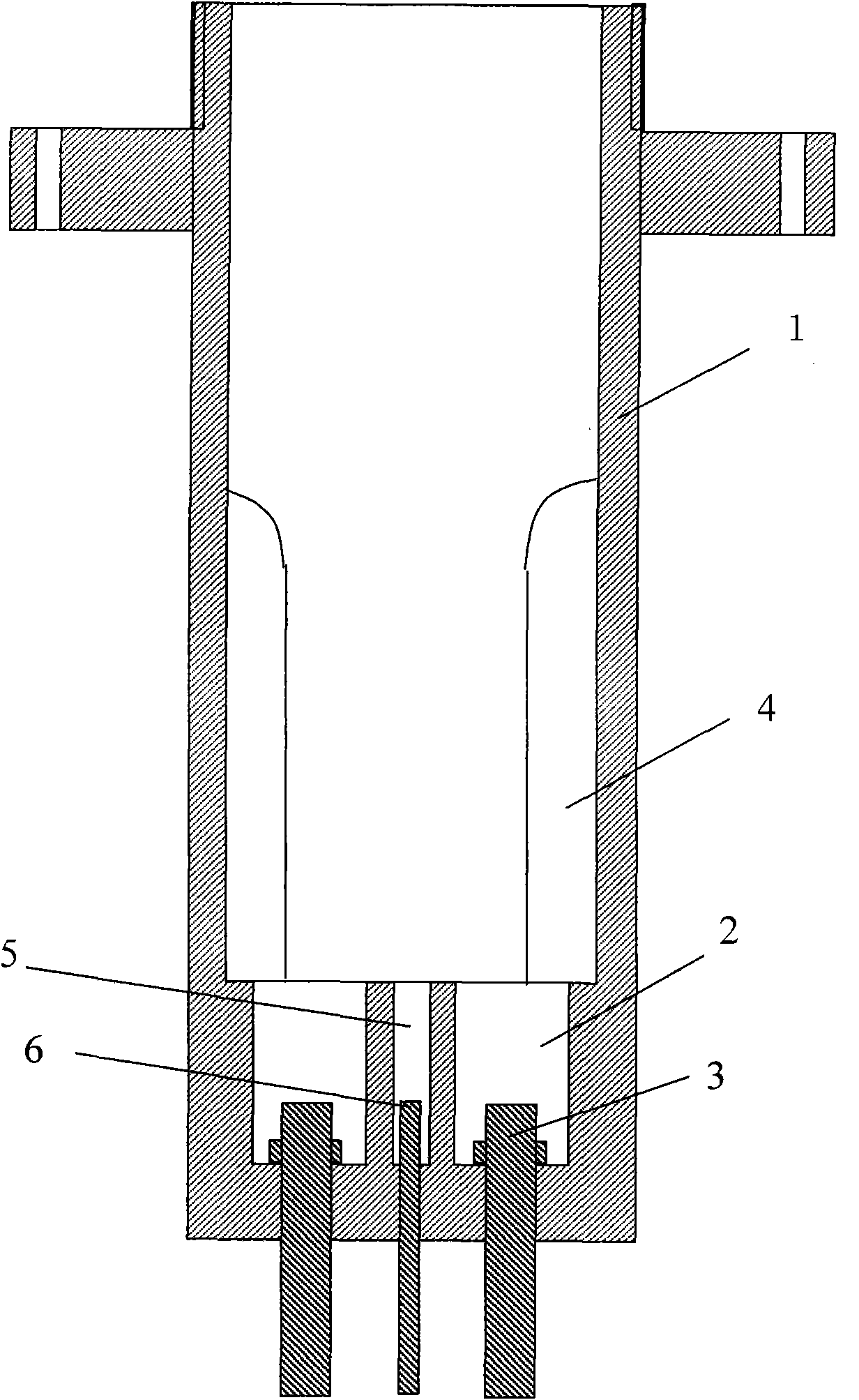

[0015] Such as figure 1 and figure 2 As shown, the high-voltage cable connector sealing cover of the present invention is composed of an insulating shell 1, wherein the top surface of the insulating shell 1 is open, and three blind holes 2 are arranged in the bottom surface of the insulating shell 1, so The axes of the three blind holes 2 mentioned above are parallel to each other, and the bottom of any blind hole 2 is fixed with a phase line static contact rod 3, and the outer diameter of the phase line static contact rod 3 is smaller than that of the blind hole 2 The inner diameter of the phase line static contact rod 3 is less than the height of the blind hole 2, and at least one rib 4 is arranged on the side wall of the inner cavity of the insulating housing 1 parallel to the axial direction of the insulating housing 1, and the insulating housing 1 The upper end is provided with an external thread.

[0016] Further, the inner cavity of the insulating housing 1 is cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com