Double-bridge automatic glass cutting machine capable of cleaning glass in conveying process

A cutting machine and automatic technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of glass debris residue, waste of labor, production efficiency, etc., and achieve the effect of saving labor and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

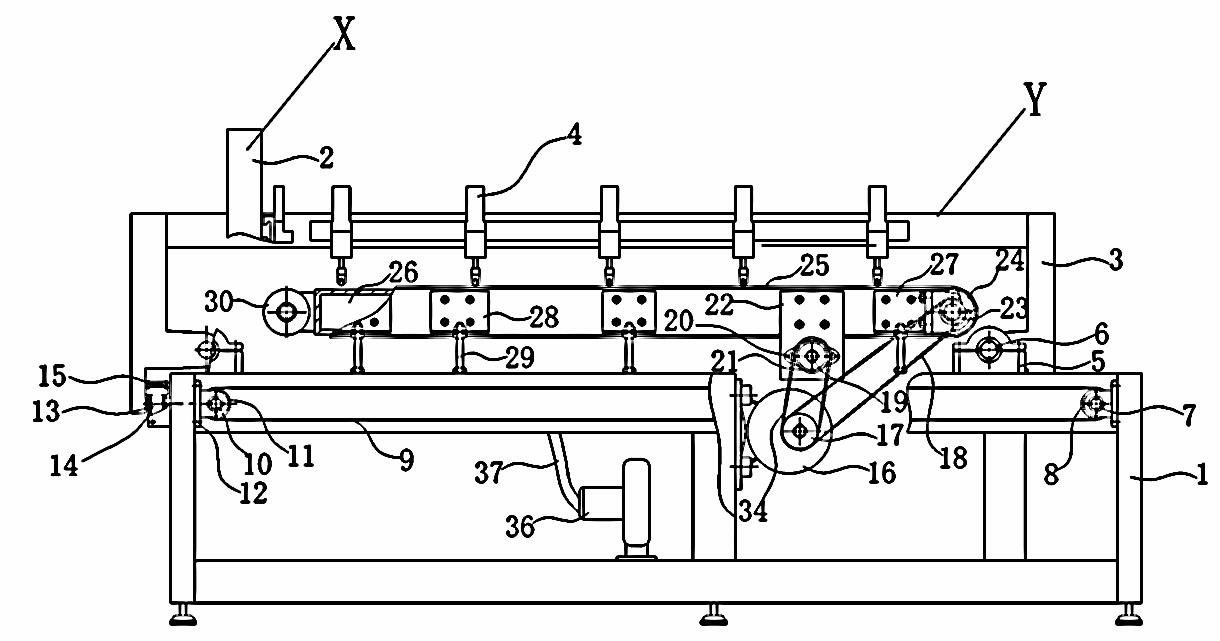

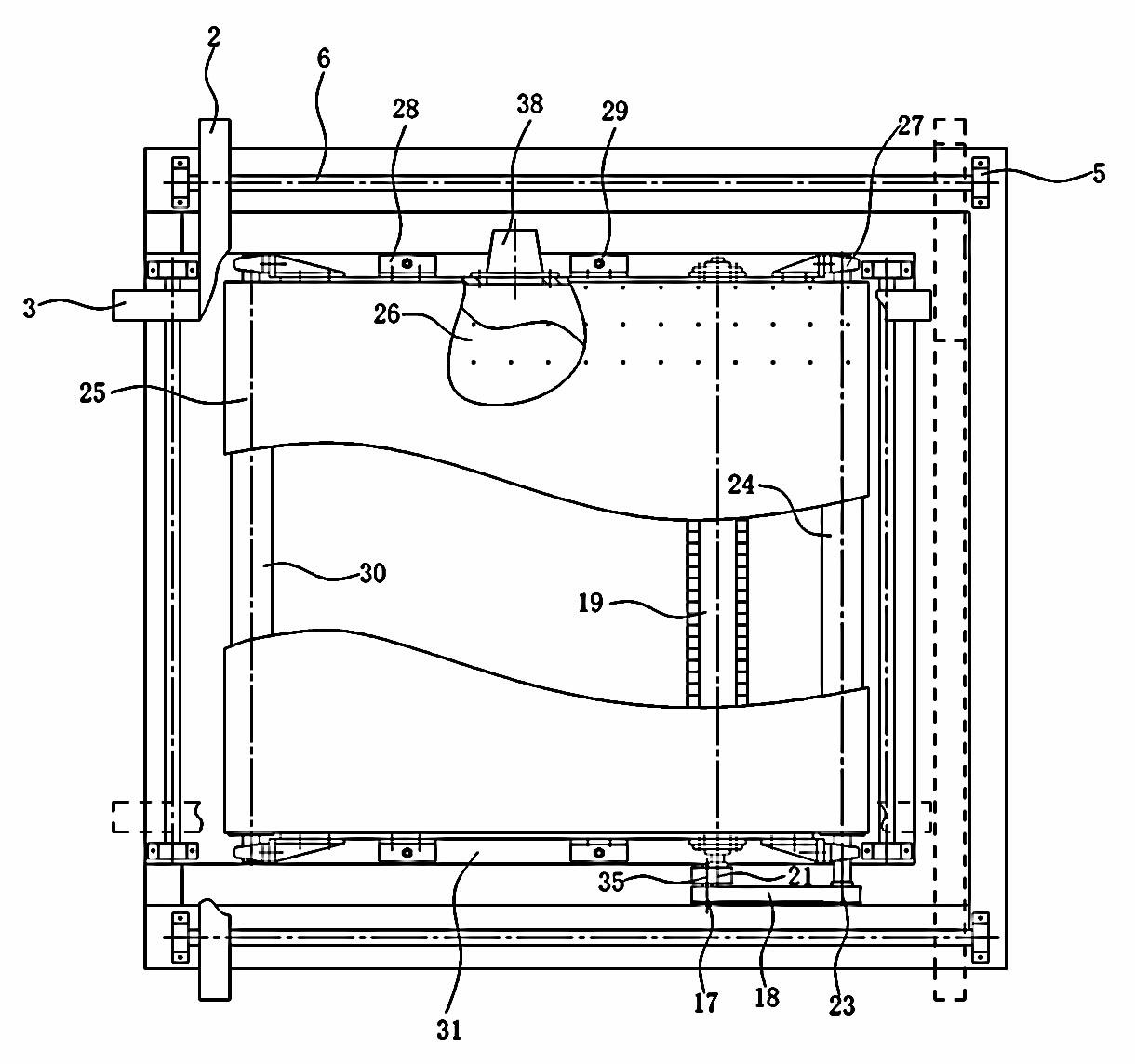

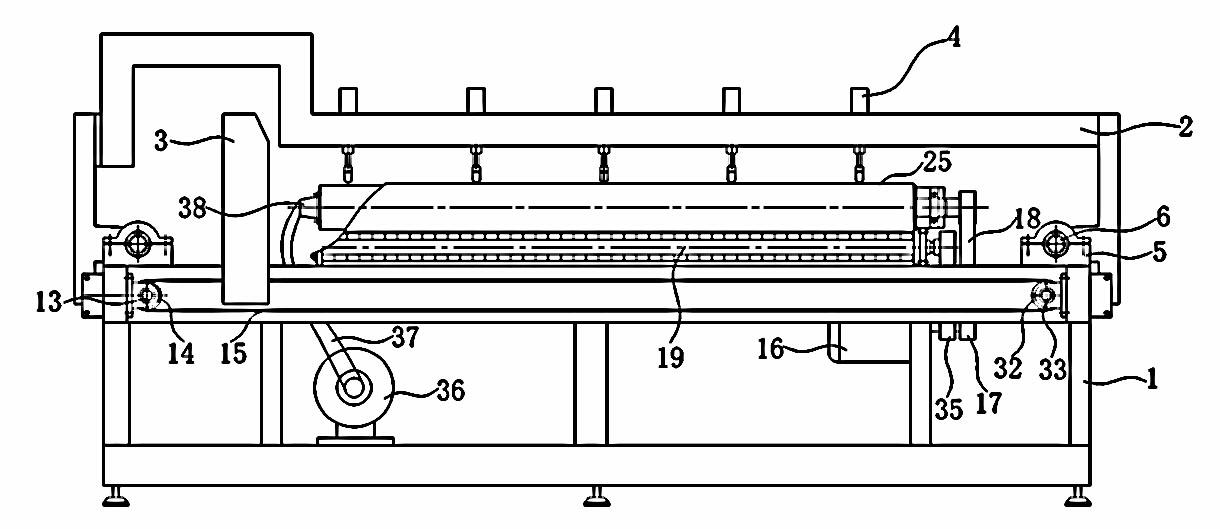

[0015] Such as figure 1 , figure 2 As shown, a conveying cleaning type double-bridge automatic glass cutting machine is provided with a frame 1, a motor 16 and a fan 36 are connected to the bottom of the frame, and a front driving pulley 17 and a front driving pulley 17 are connected to the output end of the motor. A rear driving pulley 35, the air outlet of the blower fan is connected with the ventilation pipe 37; the frame 1 is a frame similar to a back-shaped structure, and the internal frame is provided with a support workbench 31, and the top of the support workbench is provided with A rectangular support box 26; set an X beam 2 and a Y beam 3, the two ends of the two beams are connected with the frame 1 through attachments, and move back and forth in the X direction and Y direction, and the following will be described in detail in combination with specific examples illustrate.

[0016] 1. Rack beam

[0017] Such as figure 1 , figure 2 , image 3 As shown, a motor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap