Heavy-caliber O-shaped pipeline locking device

A locking device, large-diameter technology, applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, through components, etc., can solve the problems of strong power dependence, long construction period, unfavorable safety, etc., to maintain the pipeline. The effect of convenient and quick, short construction period and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with accompanying drawing:

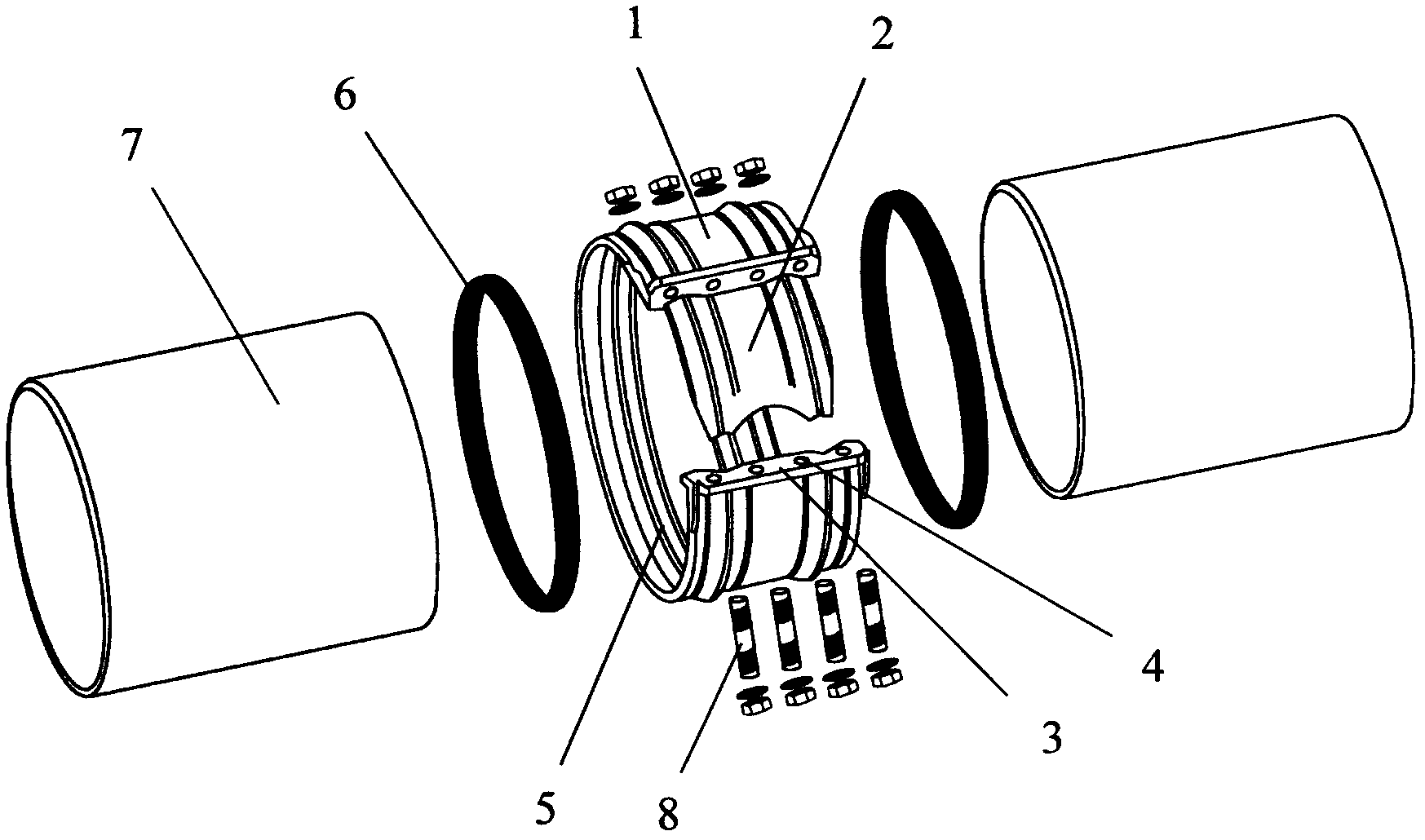

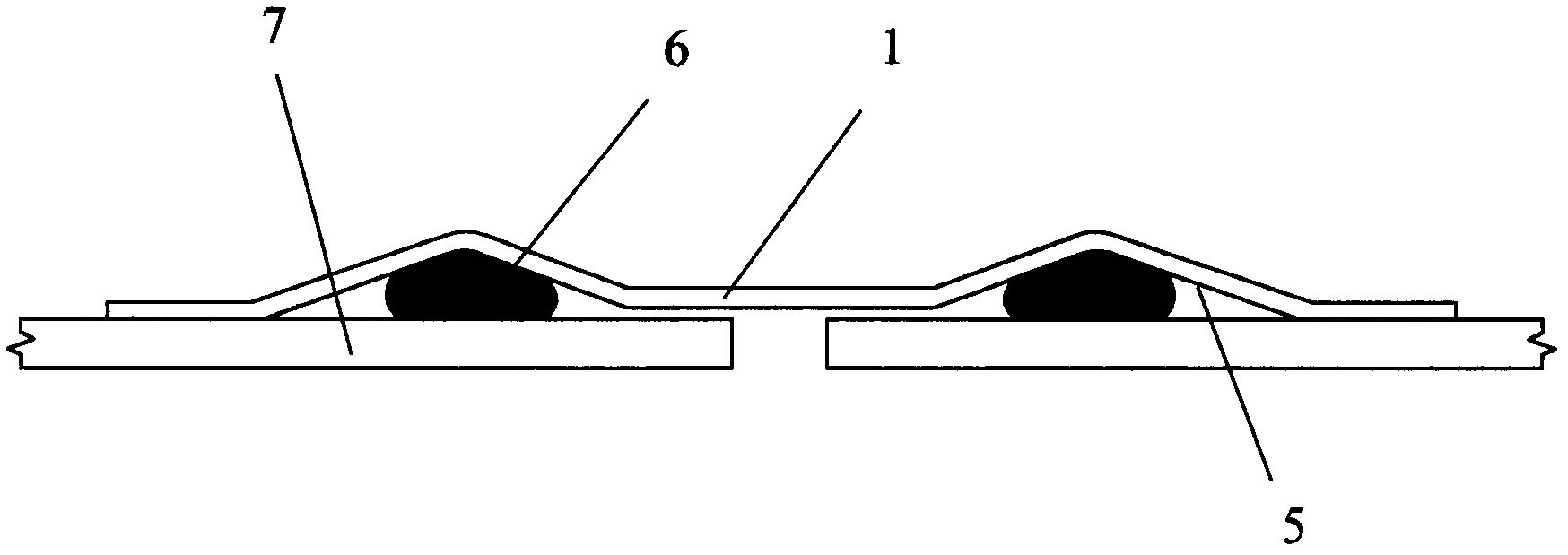

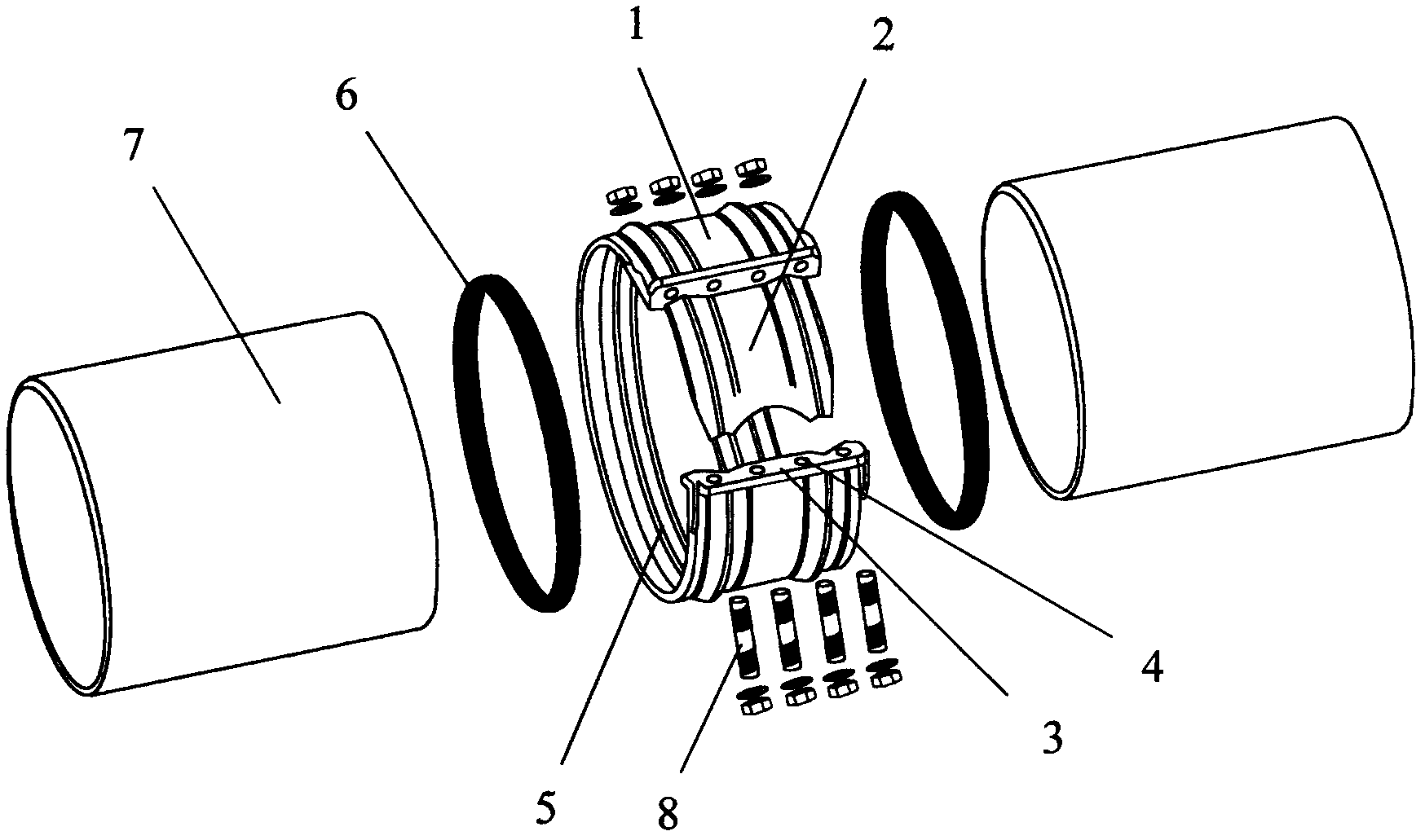

[0015] Such as figure 1 and figure 2 As shown, a large-diameter O-shaped pipeline locking device is characterized in that: the locking device includes a fastening ring 1 and a sealing platform 2, and the fastening ring 1 is provided with a fastening interface 3, and the fastening interface 3 is provided with a bolt hole 4, and the inner surface of the fastening ring 1 is provided with a pair of strip-shaped grooves 5 of the fastening ring, and the fastening interface of the fastening ring 1 at one end of the strip-shaped groove 5 3 extend out to form a sealing platform 2, the strip groove 5 is connected to and communicated with the other end through the sealing platform 2, and a sealing ring 6 is installed on the strip groove 5, and the sealing ring 6 surrounds the And lock and fix on one end of two metal pipes 7, prevent the fluid in the pipeline 7 from leaking.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com