Light-emitting module

A light-emitting module and light-emitting shaft technology, applied in optics, light guides, electric light sources, etc., can solve the problems of the dark light field of the light guide plate, the inability to effectively improve the light utilization rate, and the insufficient brightness uniformity of the light guide plate. The effect of reducing product cost and energy waste and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

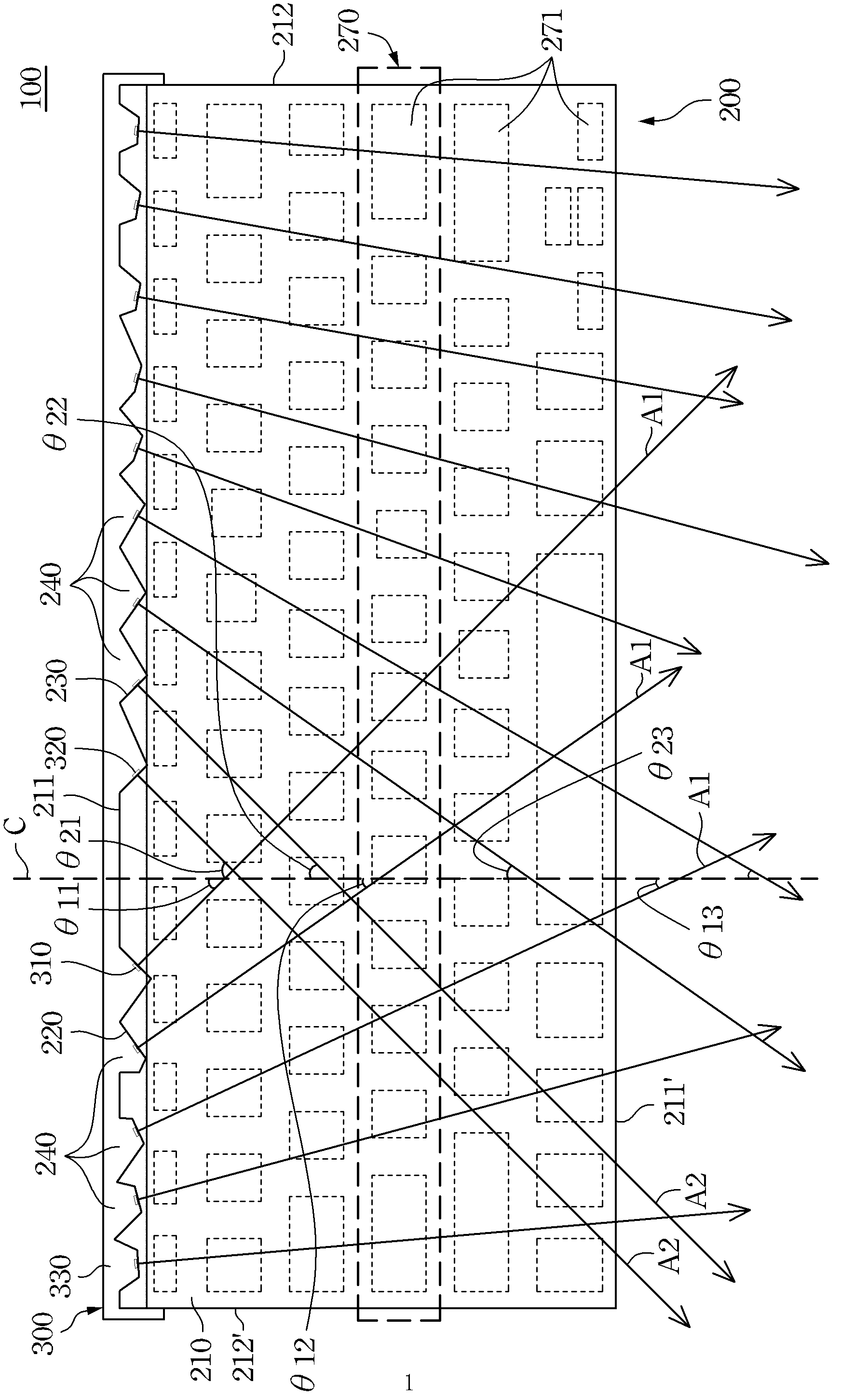

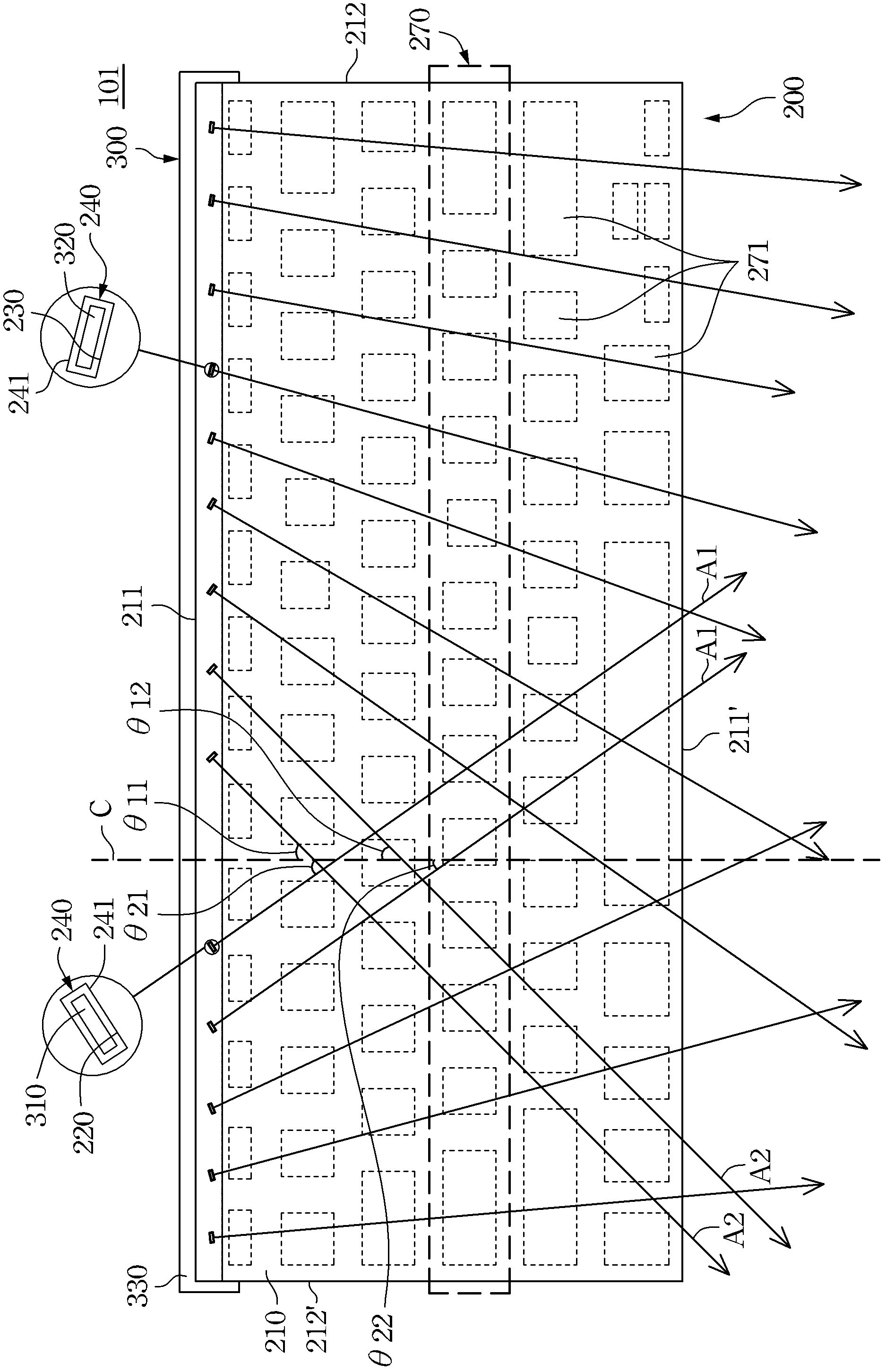

[0040] see again Figure 1Ashown. In the first embodiment of the present invention, the first light incident surface 220 and the second light incident surface 230 are arranged together on the outer side 211 of one of the long sides of the light exit surface 210 . For example, the outer side 211 of the long side of the light-emitting surface 210 includes a plurality of open first notches 240, and these first notches 240 are arranged at intervals along the extending direction of the outer side 211 of the long side, that is, on the outer side of the long side 211 presents an irregular jagged shape. The first light-incident surfaces 220 and the second light-incident surfaces 230 are respectively located in the first notches 240 one by one, and are arranged at intervals along the extending direction of the outer side 211 of the long side. However, in this first embodiment, the first notches 240 can also be a closed slot respectively, and are arranged at intervals on the outer side...

no. 2 example

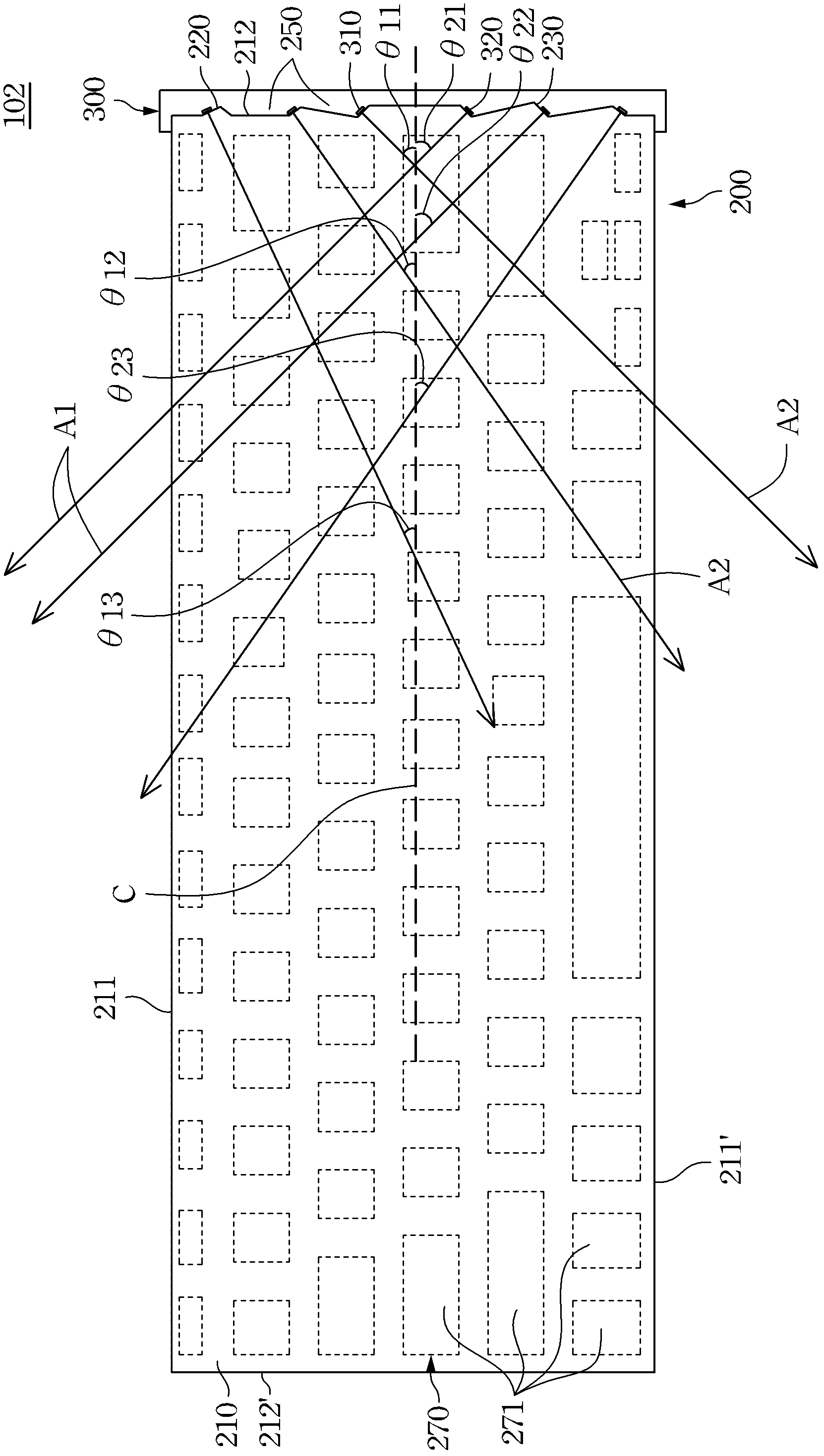

[0052] In the second embodiment of the present invention, the first light incident surface 220 and the second light incident surface 230 are arranged together on the outer side 212 of one of the short sides of the light exit surface 210 . For example, the outer side 212 of the short side of the light-emitting surface 210 includes a plurality of open second notches 250, and these second notches 250 are arranged at intervals along the extension direction of the outer side 212 of the short side, that is, on the outer side of the short side 212 presents an irregular jagged shape. The first light-incident surfaces 220 and the second light-incident surfaces 230 are respectively located in the second notches 250 one by one, and are arranged at intervals along the extension direction of the outer side 212 of the short side. However, in the second embodiment, the second notches 250 can also be a closed slot respectively, and are arranged at intervals on the outer side 212 of the short ...

no. 4 example

[0077] In the fourth embodiment of the present invention, the first light incident surface 220 and the second light incident surface 230 are co-arranged at an inner position 214 of the light exit surface 210 . The inner position 214 may be located on the light emitting surface 210 approximately across the midpoint of the outer short sides 212, 212'.

[0078] For example, the inner position 214 of the light-emitting surface 210 includes a plurality of closed fourth notches 280, such as the slots described in the first embodiment and the second embodiment, and these fourth notches 280 are along one of them. The extending directions of the outer sides 211' of the long sides are arranged at intervals. The first light-incident surfaces 220 and the second light-incident surfaces 230 are respectively located in the fourth notches 280 one by one, and are arranged in the interior of the light-emitting surface 210 at intervals along the extending direction of the outer side 211 of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com