Local cabin section model for ship impact resistance test

An anti-shock and ship technology, applied in the field of ship partial cabin model, can solve problems such as inability to obtain results, difficulty in model manufacturing, and huge cost, and achieve the effects of avoiding impact loads, improving operability, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in more detail below in conjunction with accompanying drawing example:

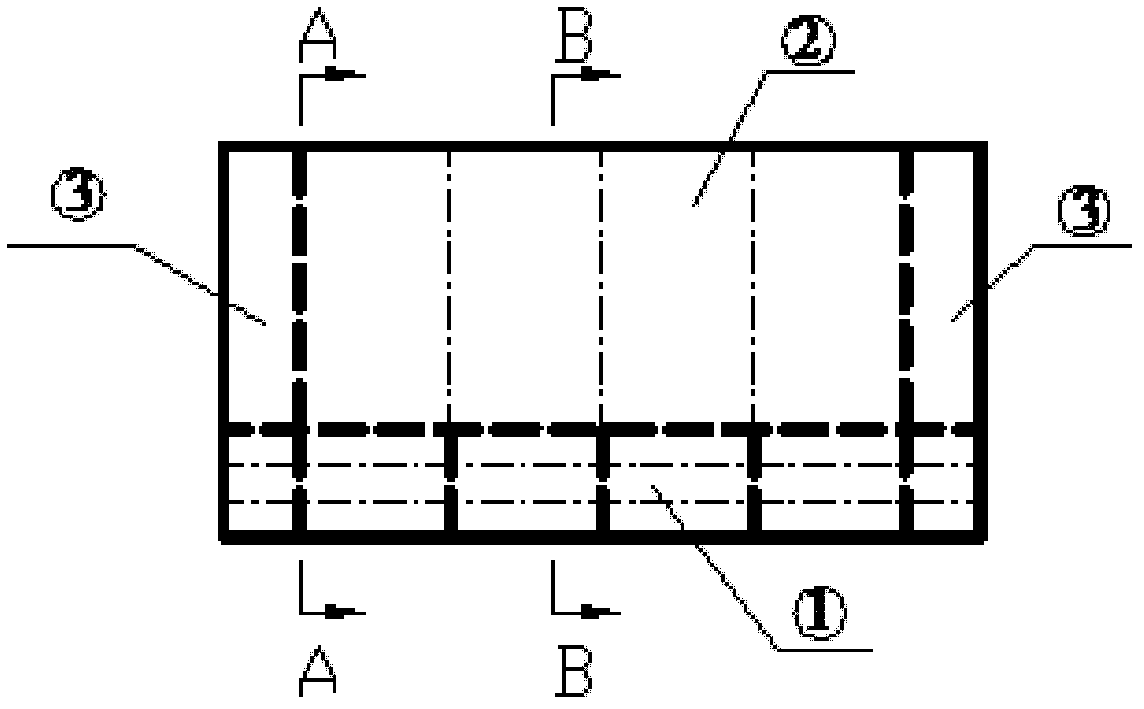

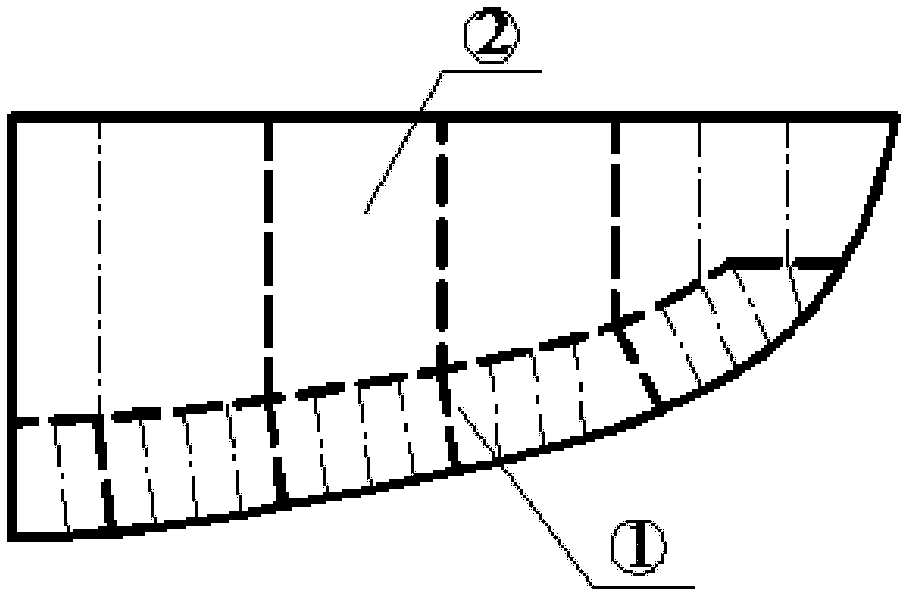

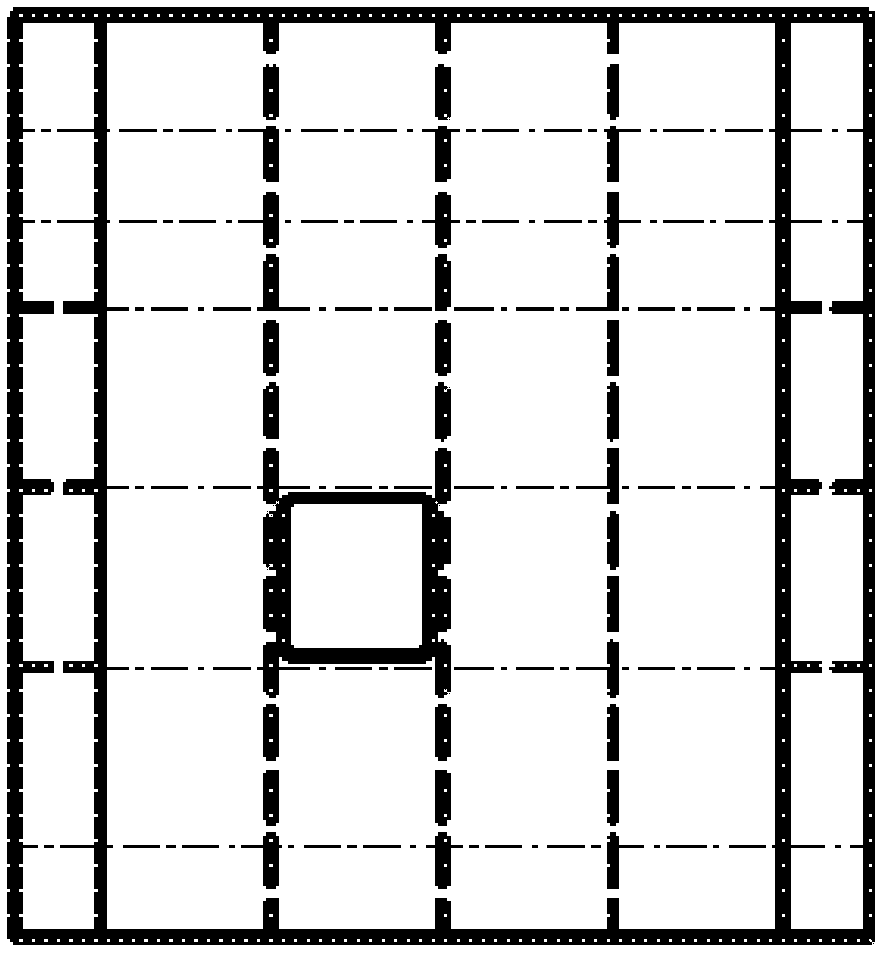

[0037] combine Figure 1-3 , the ship anti-shock test partial compartment model of the present invention is the box body that is made of double bottom tank 1, ballast tank 3 and buoyancy reserve cabin 2; Rib spacing, take half of the ship's width along the ship's width direction, and the shape of the area where it is taken vertically from the bottom of the ship to the height of 3-5 meters above the inner bottom is the same; the double bottom tank is located at the bottom, and its length is 4 -6 times the rib spacing; the length and width of the buoyancy reserve tank are the same as that of the double bottom tank, and it is located directly above the double bottom tank; the ballast tank is composed of two independent watertight tanks, which are respectively located in the double bottom tank At the front and rear positions of the buoyancy reserve cabin, the dimensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com