Process early warning method and system for analysis and estimation of full-measurement-point coupling structure

A technology of coupled structure and measurement points, applied in manufacturing computing systems, neural learning methods, prediction, etc., can solve problems such as lack of effective error correction mechanism, abnormal model estimation, and missing alarms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

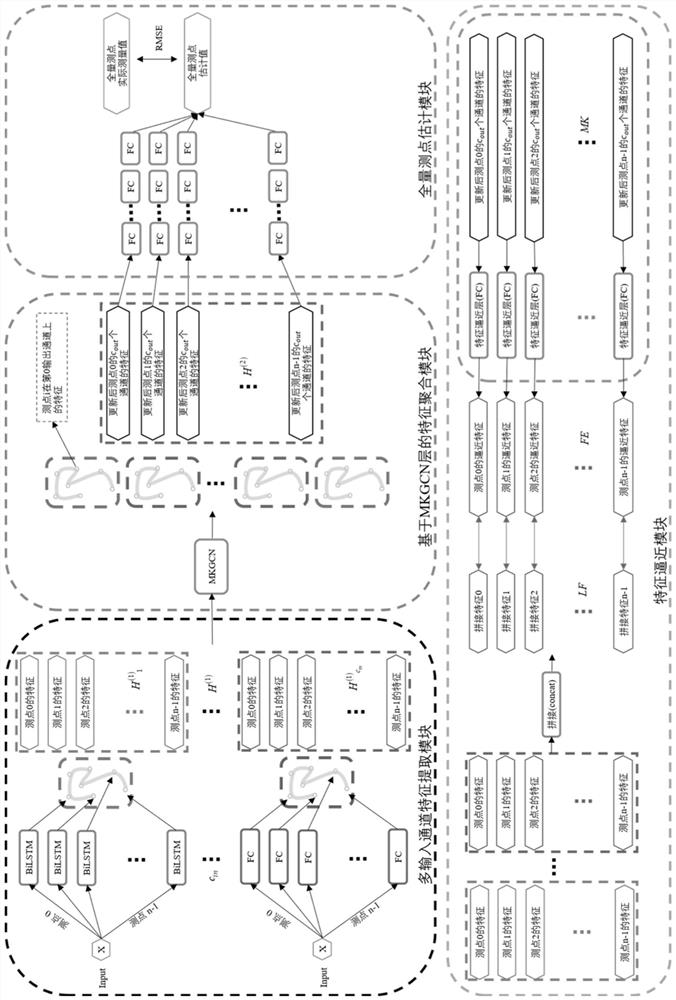

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

[0051] The data used in the present invention come from the normal data and abnormal data of the power generation process provided by a power plant in Zhejiang Province. The present invention realizes the estimation and monitoring of the measurement points of the full amount of working conditions in the industrial production process, can provide the estimated value of the full amount of measurement points, and provides abnormal information for the abnormal measurement points when an abnormal situation occurs in the system, which can effectively improve the industrial production. Troubleshooting efficiency of the process.

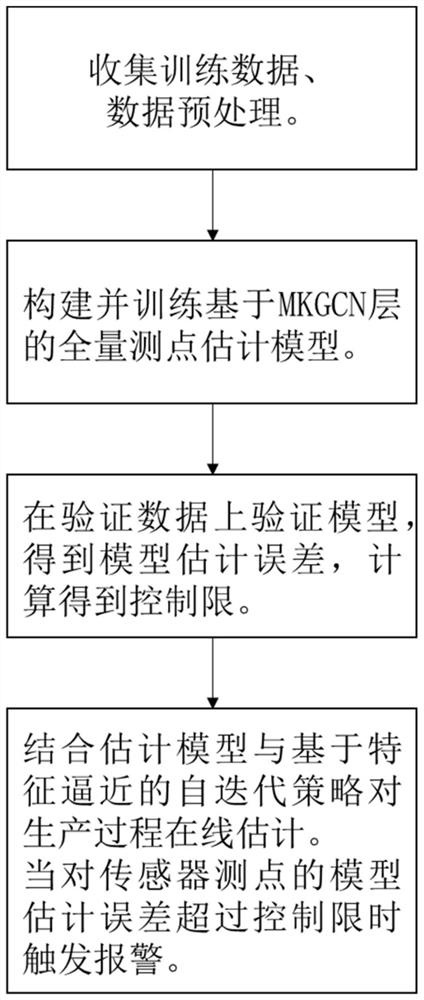

[0052] The process early warning method for coupling structure analysis and error estimation for full measurement points of the present invention includes the following steps:

[0053] Step 1) Collect data from the DC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com