Floating matrix trimming piercing die

A technology of trimming punching dies and dies, which is applied in the direction of piercing tools, metal processing equipment, manufacturing tools, etc., can solve the problems of weak strength and high production efficiency of end punching dies, and achieve good product quality and high production efficiency. The effect of improving efficiency and being easy to promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

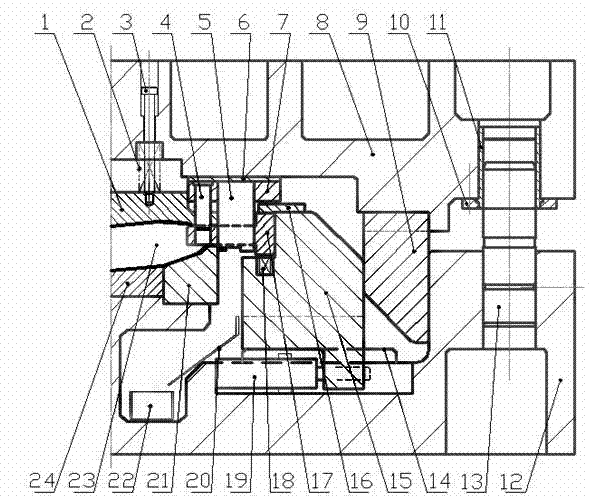

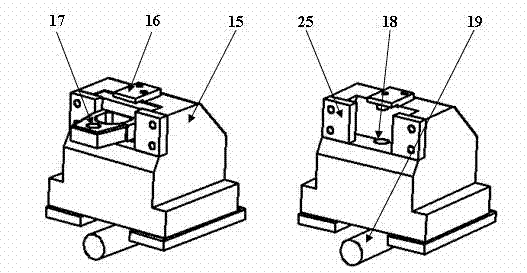

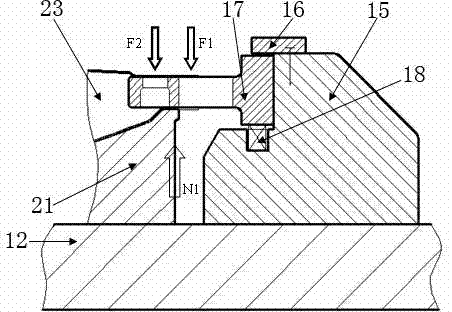

[0012] like figure 1 As shown, the working process is as follows:

[0013] First, the workpiece is put into the lower mold positioning block 24, and positioned by the shape. The upper mold moves downward together with the press slide block, and the clamping plate 1 pushes down the tubular part 23 . Under the action of the wedge 9, the slider 15 moves into the cavity of the tubular part, pushes the floating die 17 into the cavity of the part 23, and moves until the trimming edge on the upper side of the floating die 17 and the fixed die After the 21 lower side trimming edges are aligned, the slide block stops.

[0014] The slider of the press continues to move downward, the edge trimming punch 5 starts trimming, the floating die moves downward at the same time to contact the workpiece, and the upper side is trimmed, and the upper side trimming waste moves down together with the punch 5 , pass through the floating die 17, and the lower side is repaired; at the same time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com