Five-shaft numerically-controlled drilling and propelling machine

A technology of drilling, tapping and fuselage, applied in the field of five-axis CNC drilling and tapping machines, can solve the problems of inconvenient processing, low processing accuracy, short equipment stroke, etc., and achieve the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The five-axis CNC drilling and tapping machine provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

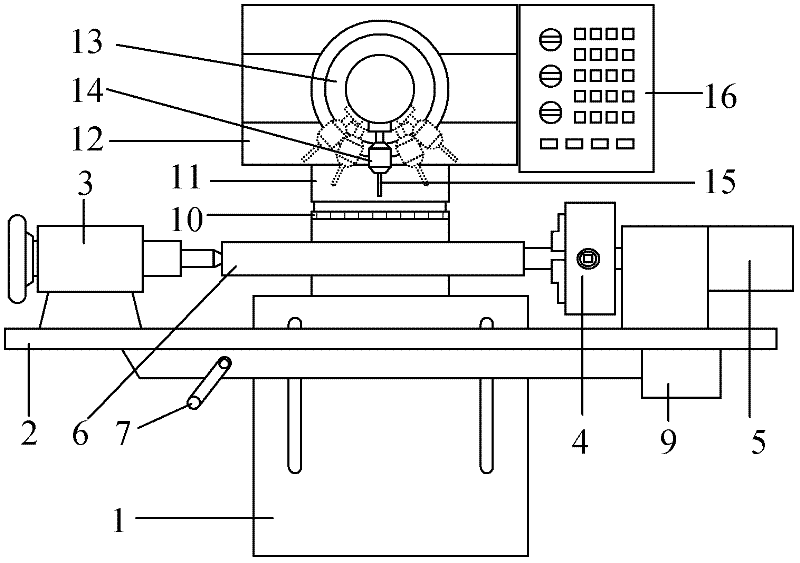

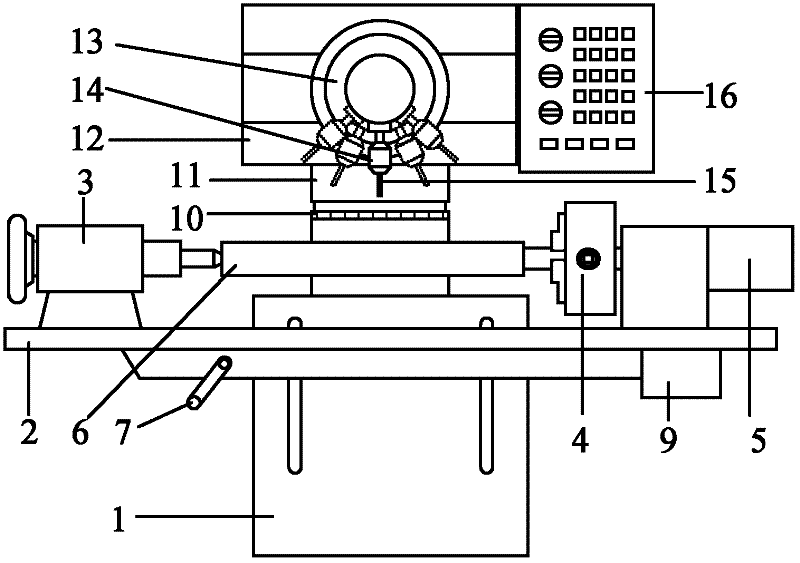

[0010] Such as figure 1 As shown, the five-axis numerical control drilling and tapping machine provided by the present invention includes: a body 1, a mobile worktable 2, a clamping head 3, a rotating head 4, a rotating motor 5, a lifting handle 7, a moving motor 9, and a rotating scale 10. Rotating disk 11, rotating head 12, indexing head 13, indexing milling head 14, milling cutter 15 and control panel 16; wherein the body 1 is set on the ground, and its upper part is provided with a fixed disk for connecting the rotating disk 11 , the top outer peripheral surface of the fixed disk is provided with a rotating scale 10 for indicating the rotation angle of the rotating disk 11; The lifting handle 7 that moves up and down is equipped with a mobile motor 9 at the right end, and the mob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com