Mould structure of plastic injection product

A technology of injection molding products and molds, which is applied in the field of mold structure of injection molding products, can solve the problems of unable to meet the normal strength requirements of products, poor strength, etc., and achieve the effect of meeting normal strength requirements and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

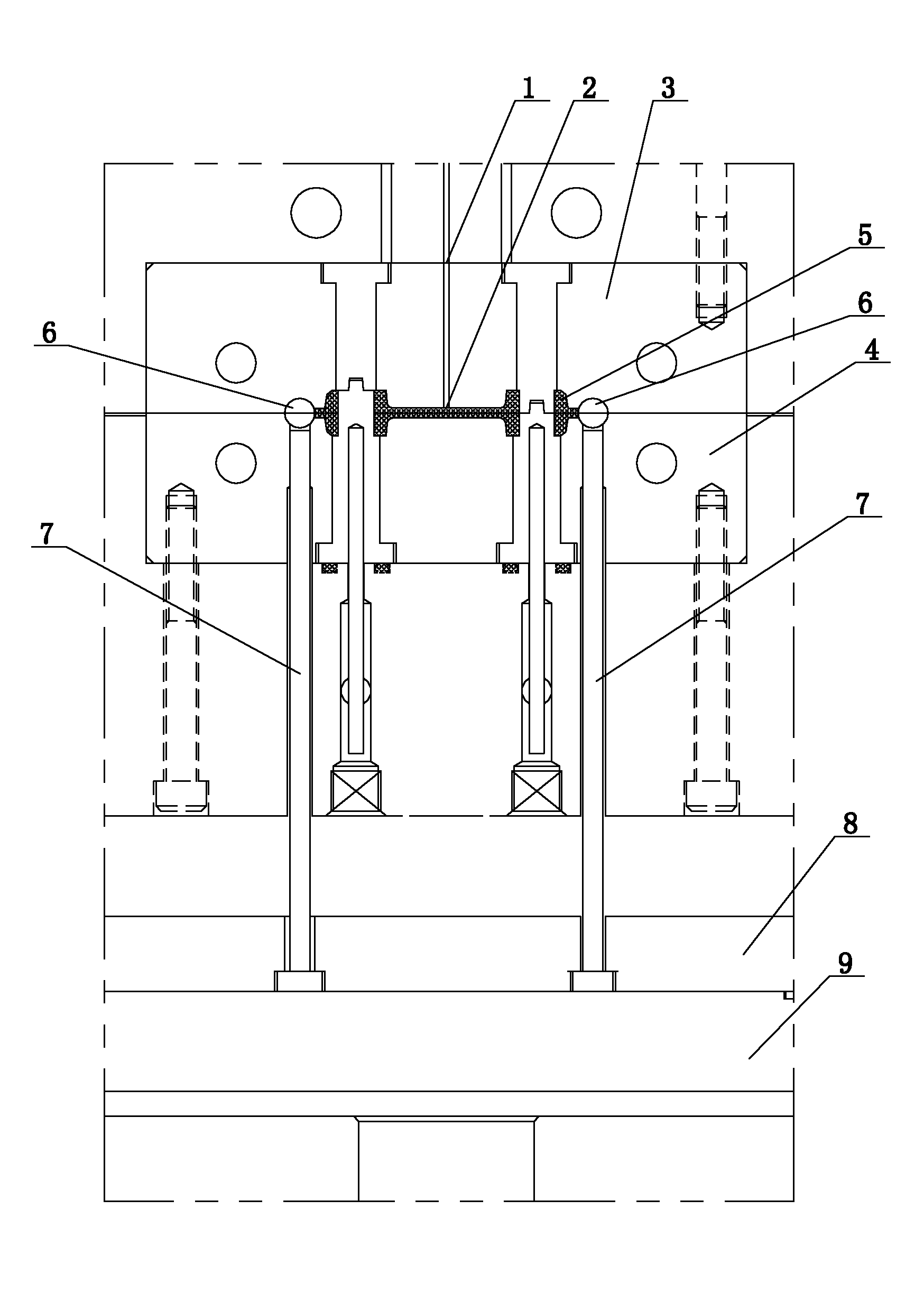

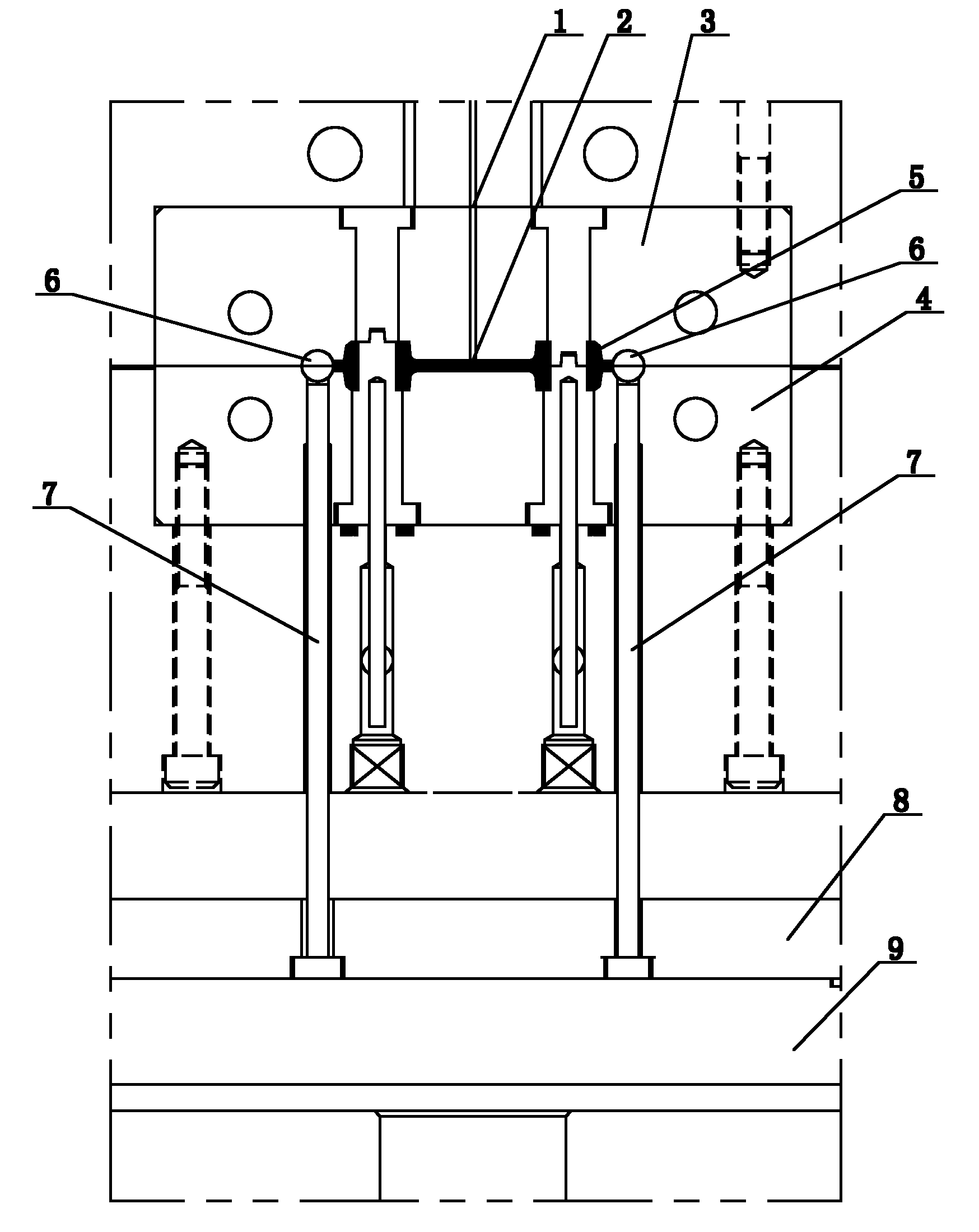

[0008] see figure 1 , Which includes runner 1, gate 2, front mold core 3, rear mold core 4, front mold core 3 and rear mold core 4 cooperate with each other to form cavity 5, runner 1 penetrates through front mold core 3 and connects to the gate 2. The cavity 5 at the farthest end of the gate 2 is provided with a cold chute 6. The cold chute 6 is specifically an overflow cavity that is formed by the cooperation of the front mold core 3 and the rear mold core 4, The lower part of the cold chute 6 is provided with a cold chute thimble 7, and the bottom end of the cold chute thimble 7 is fastened to the entirety of the needle plate 8 and the bottom needle plate 9.

[0009] The working principle is as follows: inject materials through the runner 1 until the injection is completed, and then the front mold core 3 rises, and then the cold chute thimble 7 moves to eject the rough product. Because of the cold chute thimble 7, it is no longer needed The product thimble, so that there will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com