Pipeline transportation system

A conveying system and bobbin technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material handling, etc., can solve the problems of the rising cost of the bobbin conveying system and the complicated structure of the bobbin conveying system, so as to improve the conveying process. Ability, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] First, the automatic winder 100 will be briefly described.

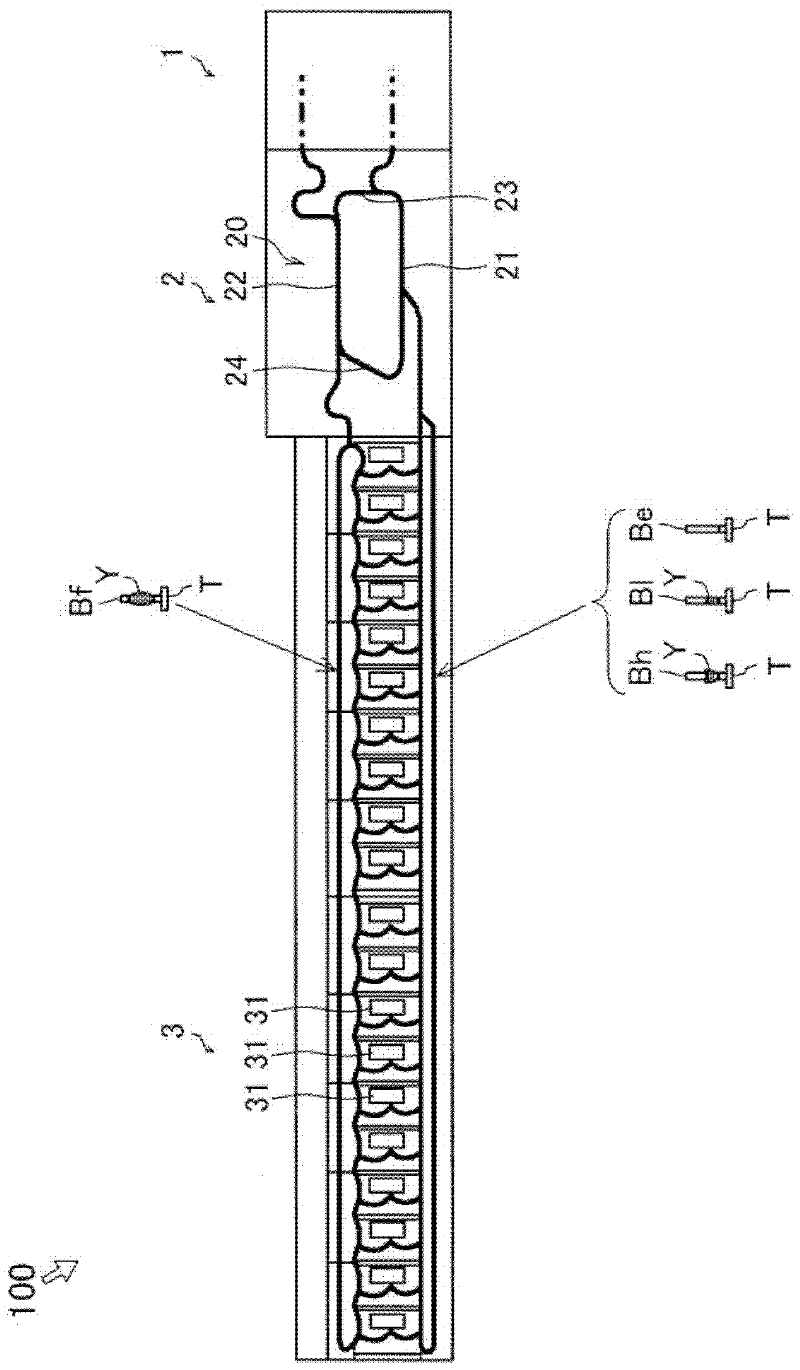

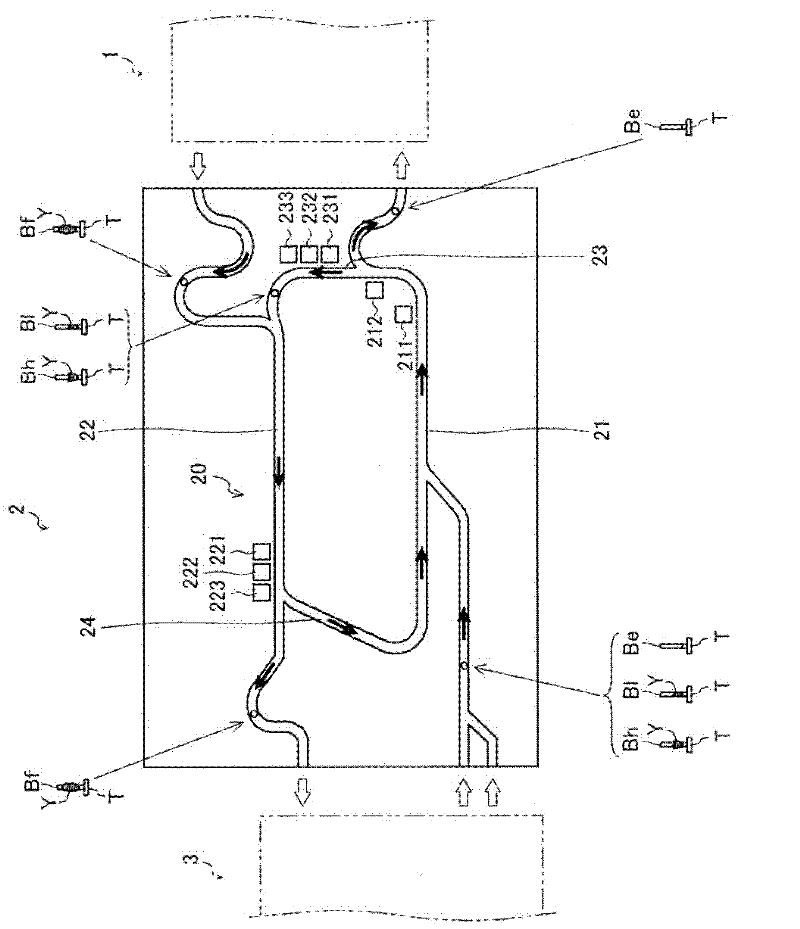

[0041] figure 1 It is a figure which shows the whole structure of the automatic winder 100. The automatic winder 100 is mainly composed of a spinning frame 1 , a bobbin conveying system 2 and an automatic winder 3 .

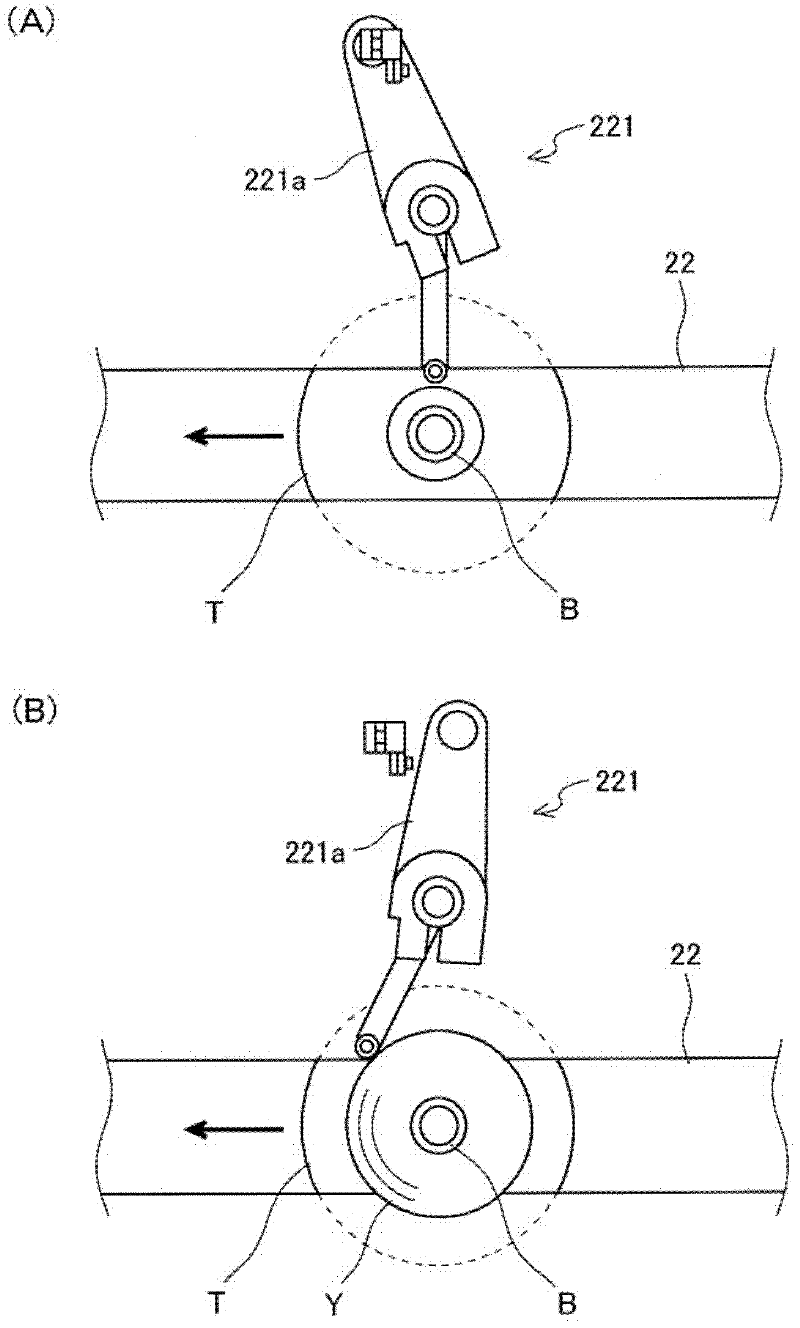

[0042] The spinning frame 1 is a ring spinning frame that draws a roving and applies twist, and winds a yarn Y having desired yarn characteristics onto a bobbin B by doing so. Then, the spinning frame 1 mounts the bobbin B wound with the yarn Y on the tray T, and supplies the tray T to the bobbin transport system 2 continuously.

[0043] The bobbin conveying system 2 conveys the tray T on which the bobbin B wound with the yarn Y is mounted to the automatic winder 3, and conveys the tray T on which the bobbin B not wound with the yarn Y is mounted to the spinning frame 1 system. Specifically, the bobbin transport system 2 transports the tray T on which the bobbin B around which the yarn Y is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com