Engine camshaft for gerontic motor tricycle

A technology for three-wheeled motorcycles and engines, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of low medium and low speed torque, poor reliability and durability, and high engine temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

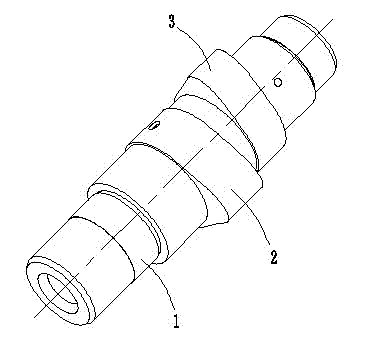

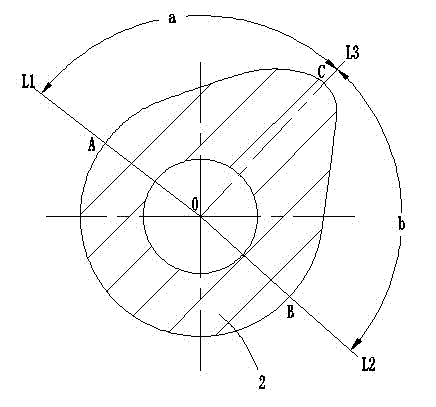

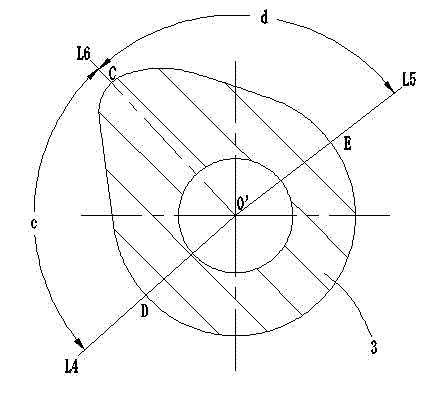

[0019] Such as figure 1 , figure 2 As shown, the camshaft of an old three-wheeled motorcycle engine has a shaft body 1 on which an intake cam 2 and an exhaust cam 3 are integrally formed. The center of the intake cam 2 is 0, the line connecting the center 0 of the intake cam 2 and the starting point A of the intake cam profile is on the first straight line L1, and the center 0 of the intake cam and the end point of the intake cam profile The line connecting B is on the second straight line L2, the line connecting the intake cam center 0 and the outermost edge point C of the intake cam flange is on the third straight line L3, and the line between the first straight line L1 and the third straight line L3 The angle between them is a, and 92°≤a≤98°. In this embodiment, a is preferably 95°; the angle between the second straight line L2 and the third straight l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com