Connection structure of low-emission double-stroke gasoline engine silencer

A muffler and two-stroke technology, applied in the direction of mufflers, machines/engines, exhaust devices, etc., can solve the problems of reduced tensile strength, difficult discharge, loose mufflers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

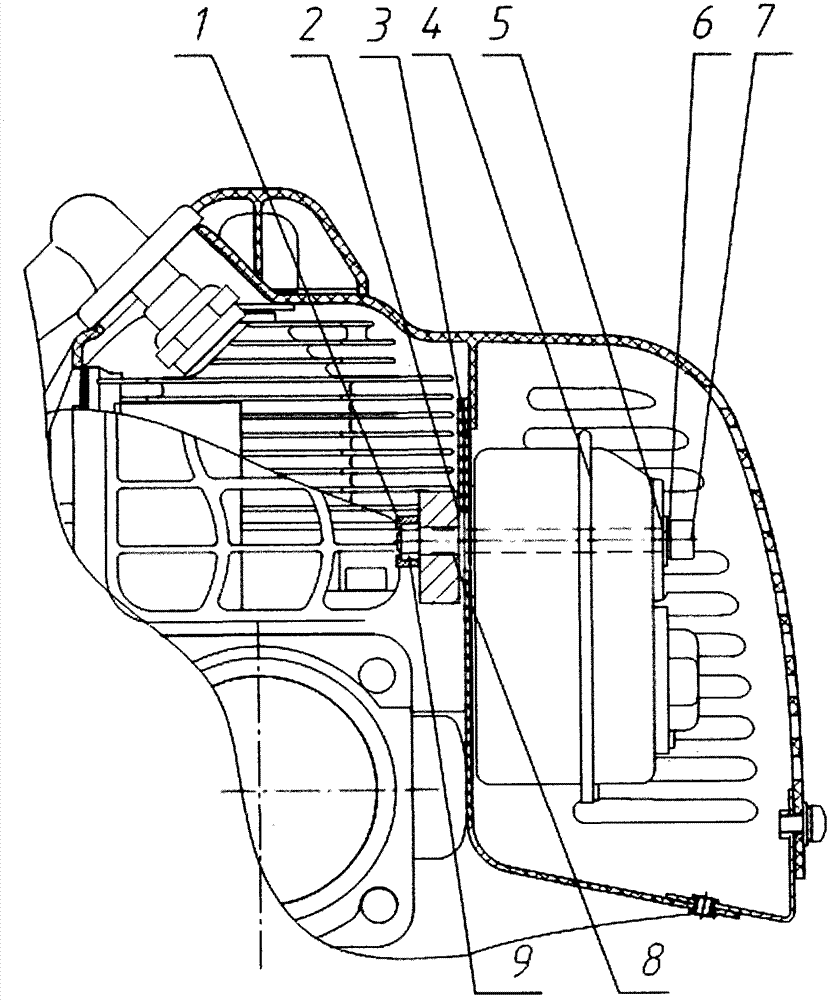

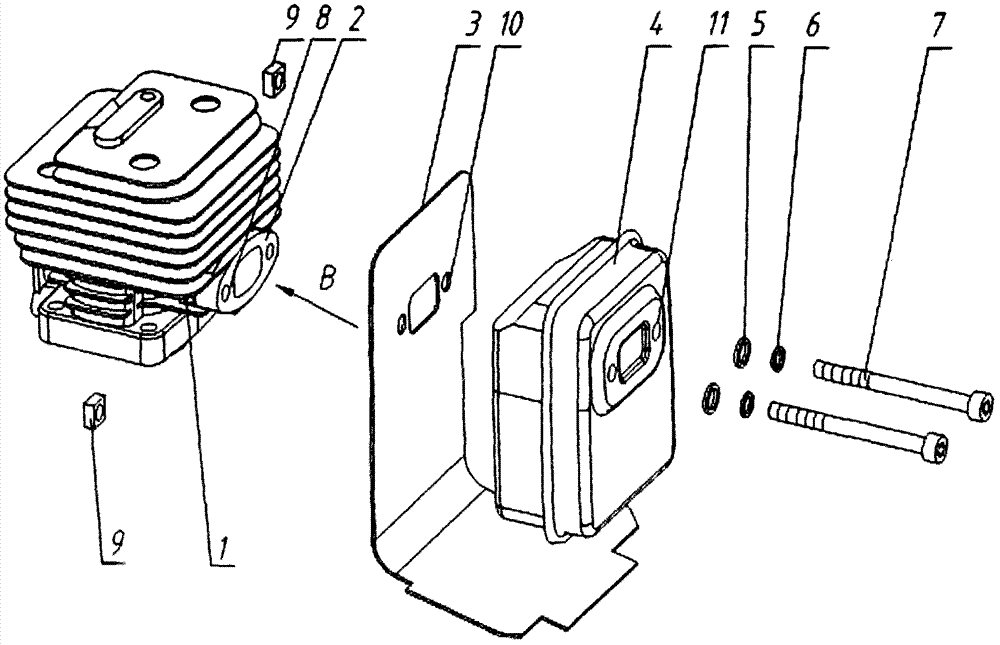

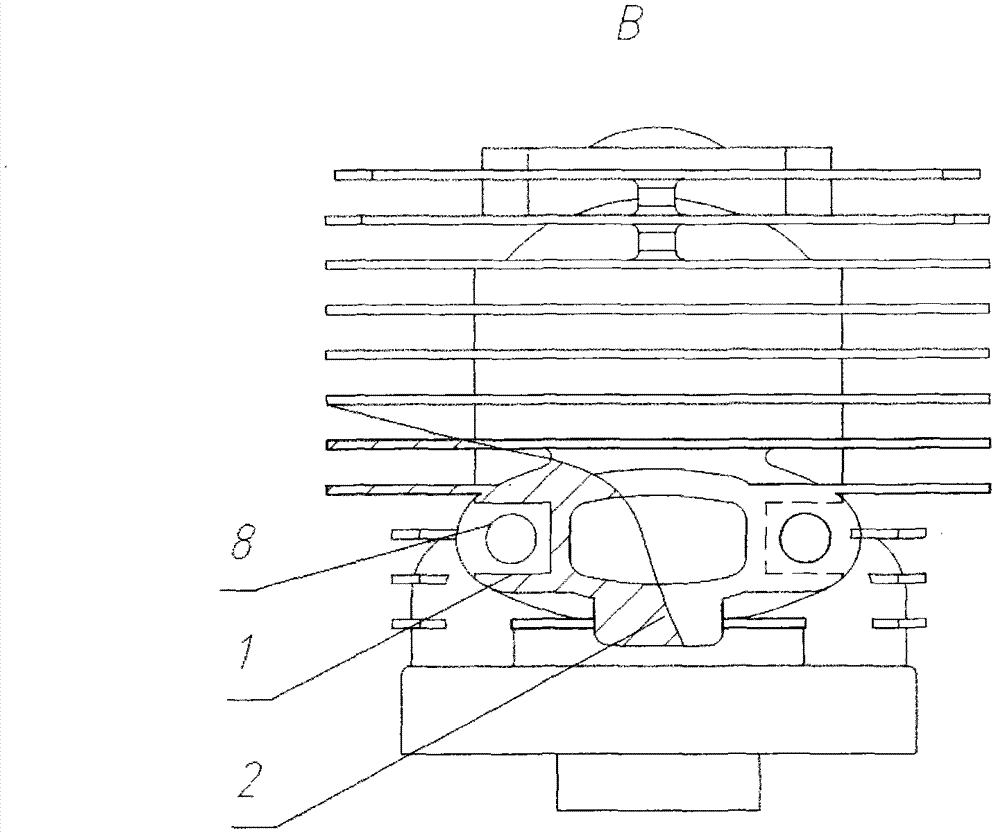

[0013] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the muffler connection structure of the present invention is composed of exhaust flange 2 (nut placement chamber 1, bolt hole 8), muffler pad 3 (muffler pad hole 10), muffler 4 (muffler hole 11), flat Washer 5, spring washer 6, bolt 7 (bolt head 12), nut 9 are formed.

[0014] The nut placement chamber 1 is on the side of the exhaust flange 2 facing the cylinder body, the bolt holes 8 are arranged symmetrically in the exhaust flange 2, and the two nut placement chambers 1 coincide with the centerlines of the two bolt holes 8 respectively; the exhaust flange 2 The side facing away from the cylinder body is the muffler pad 3, the muffler 4, the flat washer 5, and the spring washer 6; When the bolt head 12 is placed in the nut placement chamber 1, the threaded end penetrates from the bolt hole 8 and connects with the nut 9 in turn.

[0015] The specific working process is as follows:

[0016] Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com