Method and device for preventing plunger pump from sucking air

A plunger pump and anti-suction technology, which is applied in the field of anti-cavitation, can solve the problems of reducing the service life of hydraulic plunger pumps, the inability to pressurize the fuel tank, cavitation of hydraulic plunger pumps, etc., so as to avoid cavitation and reduce Maintenance cost, effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

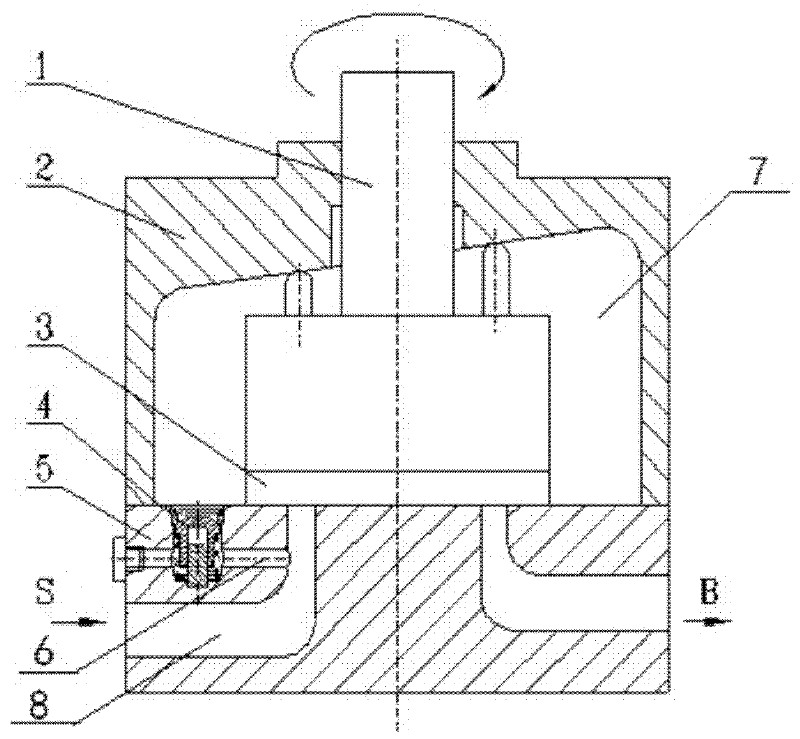

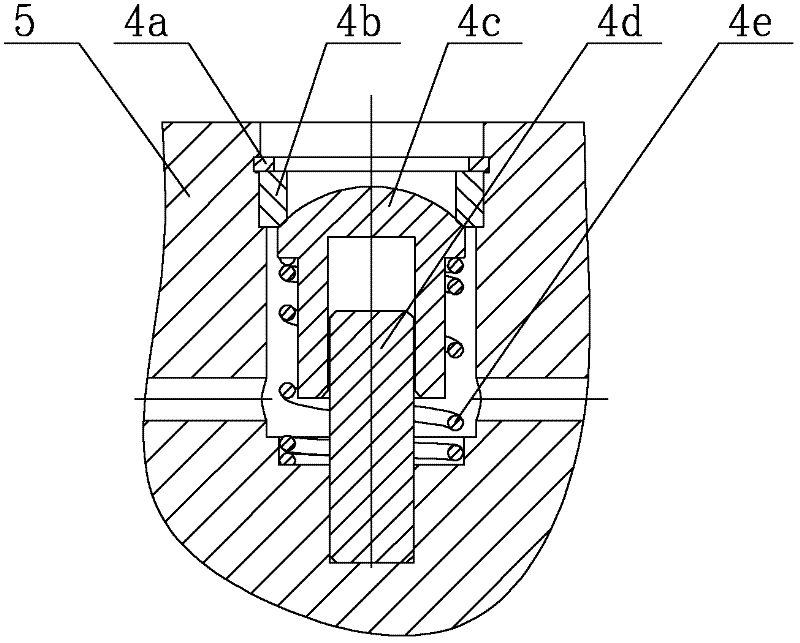

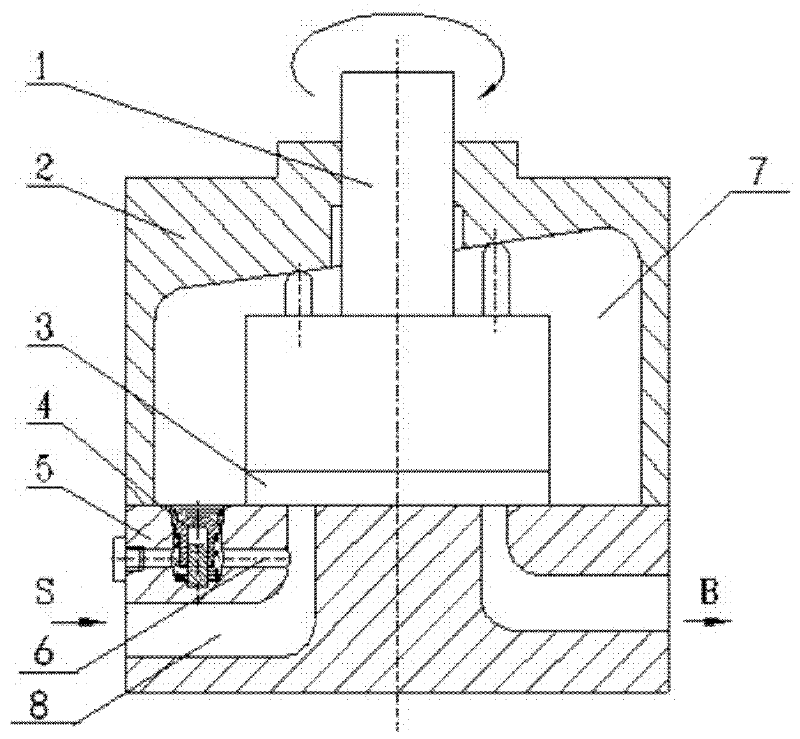

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0016] Example. A plunger pump anti-cavitation method, in which a one-way connection is made between the casing cavity of the plunger pump and the oil suction channel of the rear cover, so that the hydraulic oil in the casing cavity enters the oil suction channel for oil replenishment after negative pressure occurs in the oil suction channel, Prevent the oil suction channel of the plunger pump from being sucked empty.

[0017] After negative pressure appears in the oil suction channel, the hydraulic oil in the housing cavity enters the oil suction channel for oil replenishment. When the hydraulic oil required by the oil suction channel is greater than the oil supply from the oil suction port, the hydraulic oil in the housing cavity enters the oil suction channel for oil replenishment. .

[0018] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com