On-line diameter measurement device for large-diameter solid of revolution

A technology of measuring devices and rotators, applied to measuring devices, optical devices, instruments, etc., can solve the problems of high manufacturing cost and low measurement accuracy, and achieve the effects of low manufacturing cost, high measurement accuracy and avoiding manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] With reference to accompanying drawing, further illustrate the present invention:

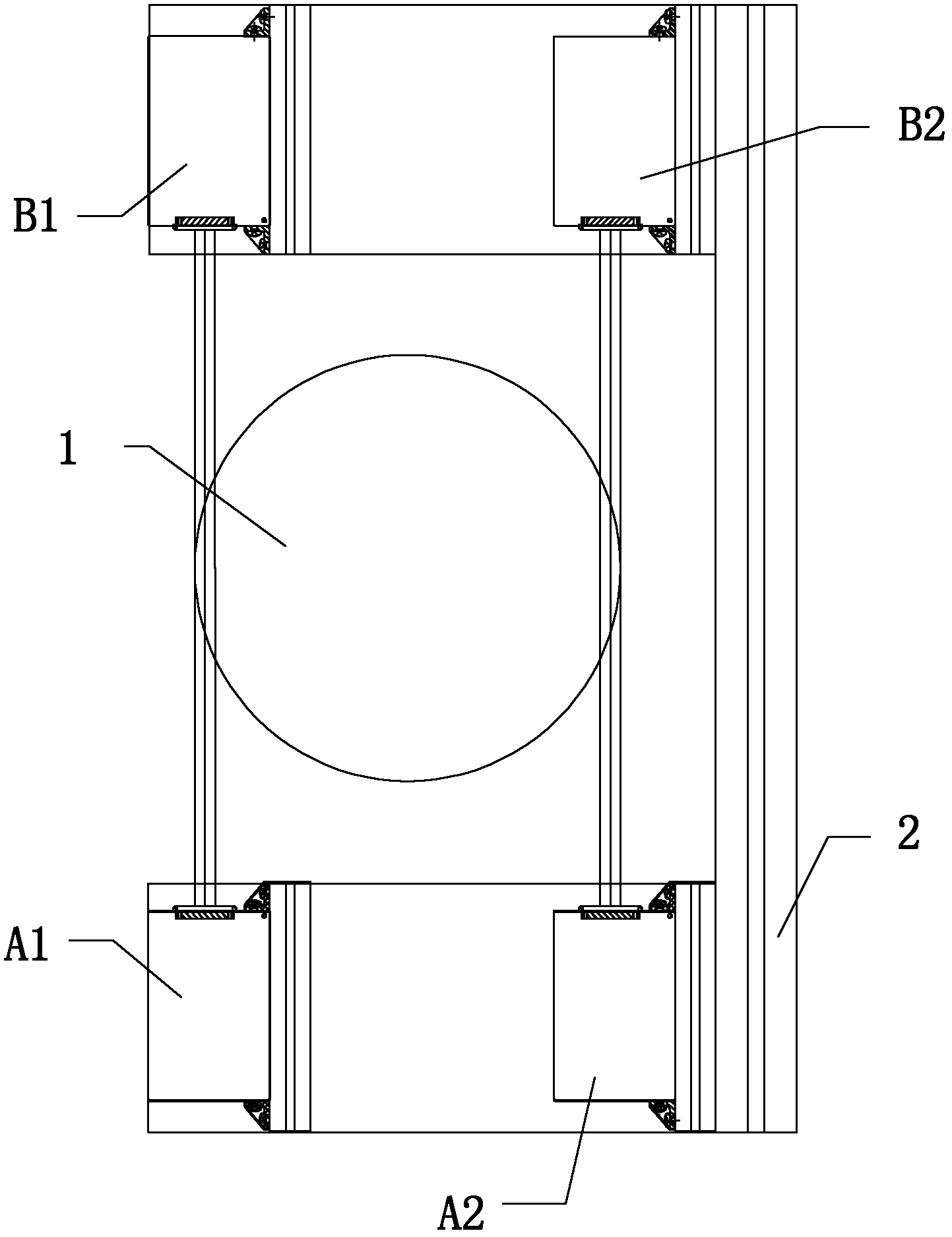

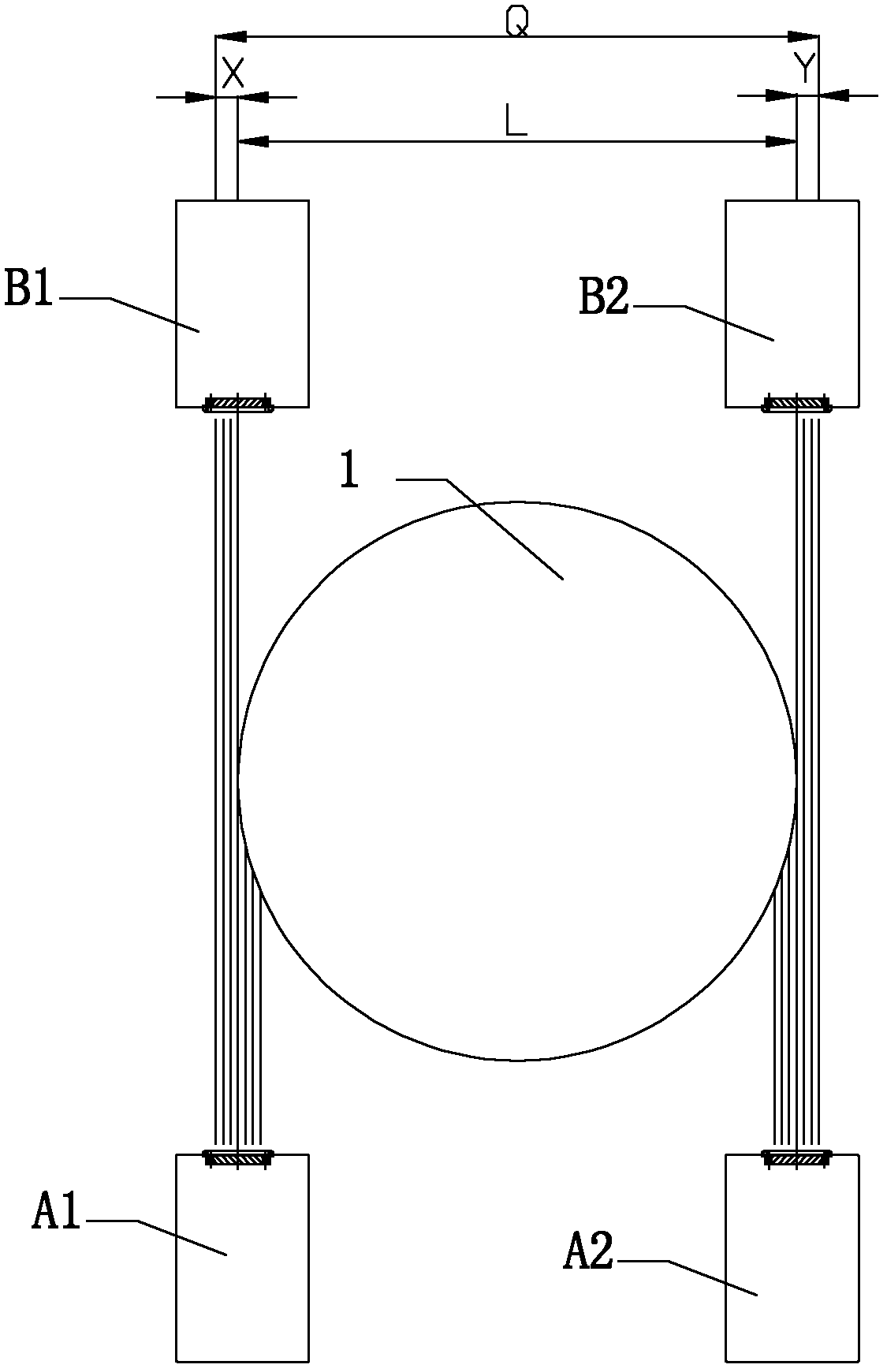

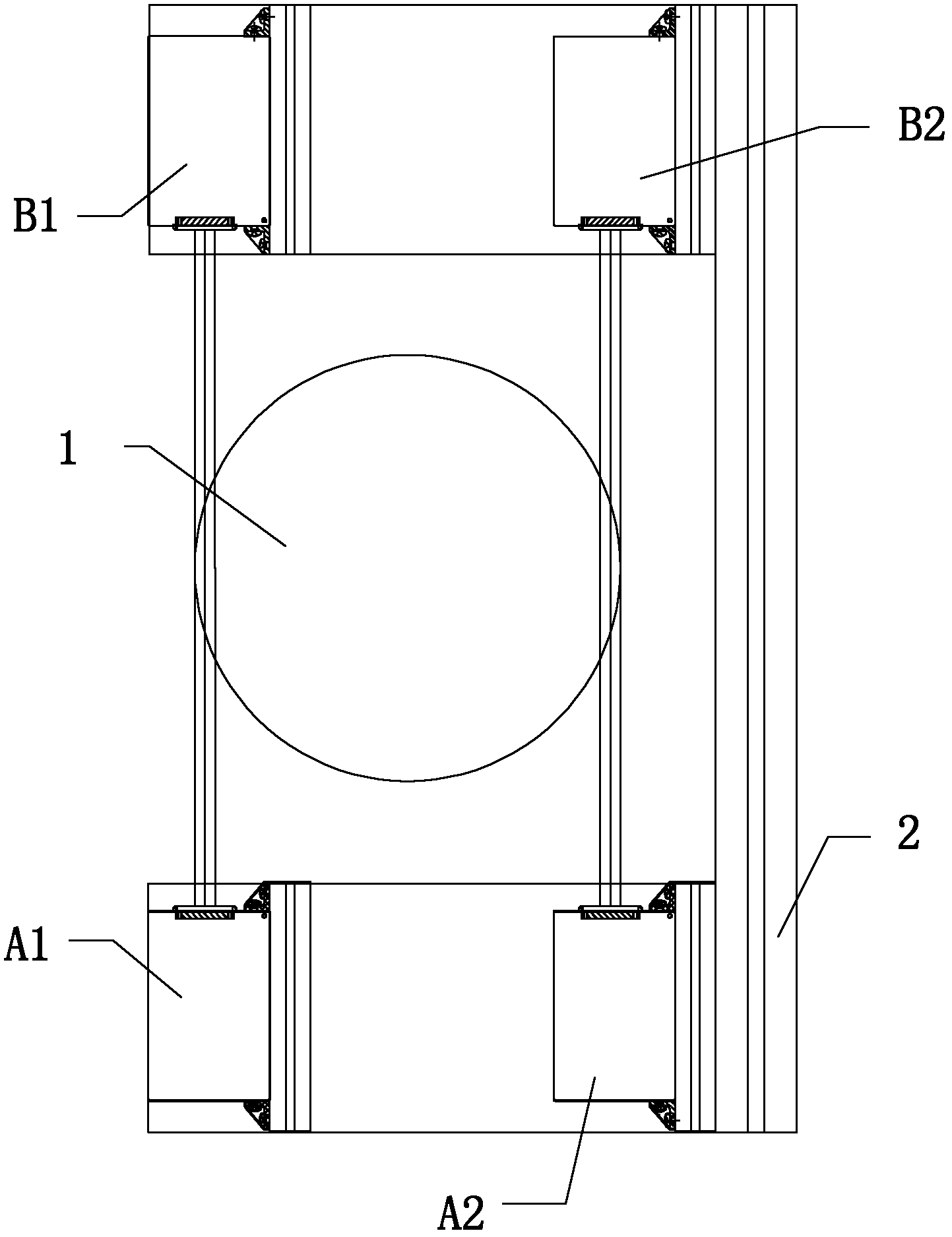

[0024] An online diameter measuring device for a large-diameter revolving body, including the first measuring group A1, B1 and the second measuring group A2, B2 symmetrically arranged on both sides of the revolving body to be measured, the first measuring group A1, B1 and the second measuring group A2 and B2 are arranged symmetrically with respect to the axis of the tested rotating body 1, and the two measurement groups are respectively aligned with the two ends of the tested rotating body 1;

[0025] Each measurement group includes transmitting ends A1, A2 for emitting measurement light, receiving ends B1, B2 aligned to the transmitting ends, and a connecting piece 2 connecting the transmitting ends A1, A2 and receiving ends B1, B2, the described The tested rotary body 1 is located between the transmitting ends A1, A2 and the receiving ends B1, B2, and the measuring light encounters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com