Automatic dropwise adding controller for polishing liquid

A polishing liquid and controller technology is applied in the field of polishing drop addition controller, which can solve the problems of polishing liquid waste and uneven polishing liquid, and achieve the effect of good polishing effect, uniform liquid drop, and saving polishing liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

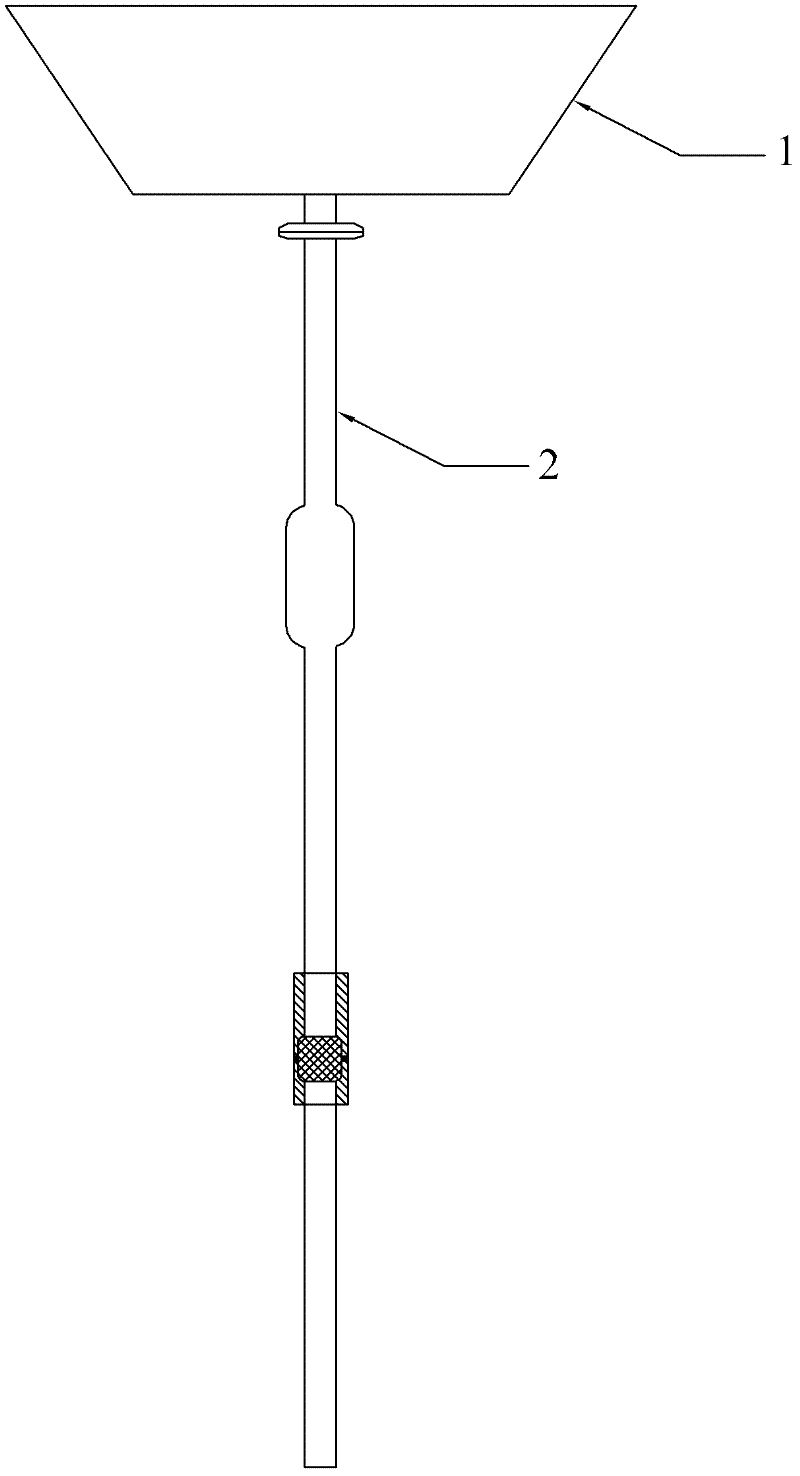

[0010] Specific implementation mode 1. Combination figure 1 Illustrate this specific embodiment, the automatic dripping controller of polishing liquid, it comprises liquid storage container 1 and infusion tube 2, and liquid storage container 1 is positioned at the top of infusion tube 2, and the liquid inlet of described infusion tube 2 is connected with liquid storage container 1 The bottom is connected.

[0011] In this specific embodiment, the infusion tube 2 can be a medical infusion tube, or the filter of the medical infusion tube and below can be cut off, and the large-diameter catheter can be directly used for dripping, and the controller of the infusion tube 2 can control the infusion tube 2 every time. The flow rate and flow rate of the secondary liquid can be controlled, so as to realize the automatic dripping of the polishing liquid.

specific Embodiment approach 2

[0012] Embodiment 2. The difference between this embodiment and the polishing liquid automatic dropping controller described in Embodiment 1 is that the inner diameter of the infusion tube 2 is between 4mm and 8mm.

specific Embodiment approach 3

[0013] Embodiment 3. The difference between this embodiment and the controller for automatic dripping of polishing liquid described in Embodiment 1 is that the inner diameter of the infusion tube 2 is 6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com