Automatic liquid dropping device applied to fungus organism cultivation

A biological and automatic technology, applied in plant cultivation, cultivation, application, etc., can solve the problems of increased production cost, large amount of operation, uneven artificial dripping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

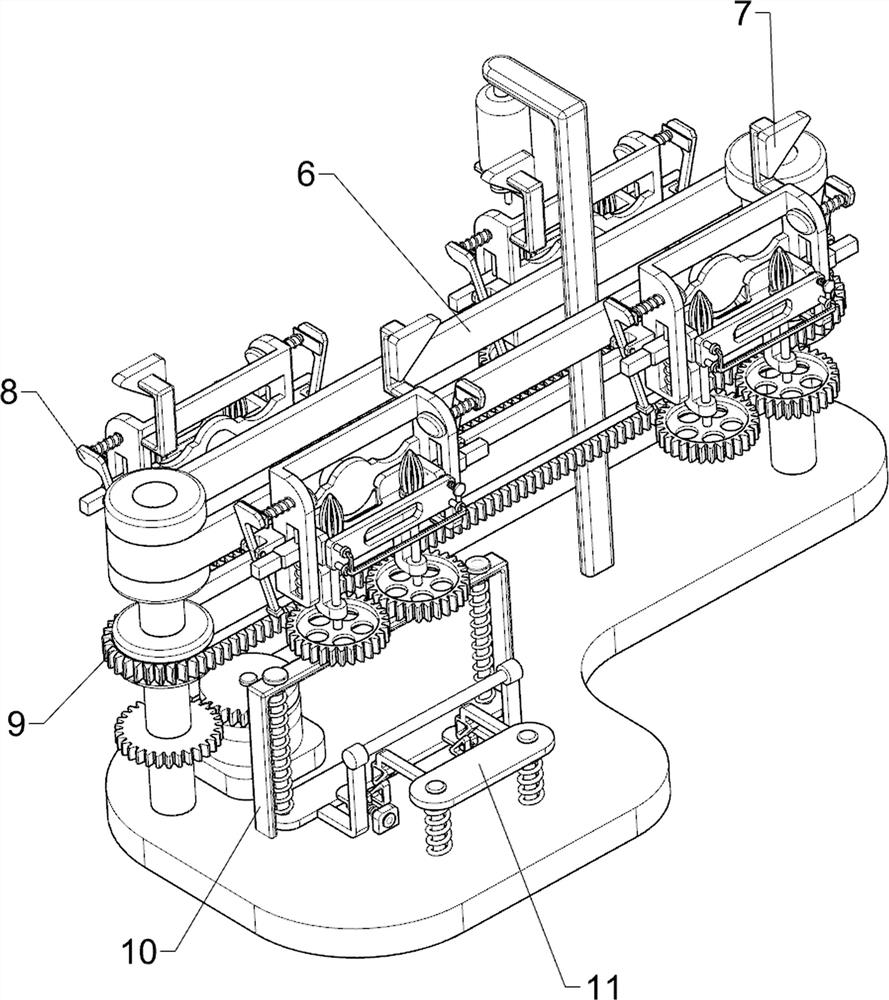

[0045] A kind of automatic liquid dripping device that is applied to bacteria biological cultivation, such as figure 1 and figure 2 As shown, it includes a base plate 1, a support rod 2, a material barrel 3, a pressing block 4, a first spring 5, a rotating mechanism 6 and a fixing mechanism 7. A material barrel 3 is provided, and the bottom of the material barrel 3 is slidingly provided with a briquetting block 4, a first spring 5 is connected between the briquetting block 4 and the bottom of the material barrel 3, and a turning mechanism 6 is arranged on the rear side of the bottom plate 1 top. There is a fixing mechanism 7 .

[0046] The staff can place the nutrient solution in the material barrel 3, the nutrient solution in the material barrel 3 will not flow out in the initial state, then place the petri dish with bacteria in the fixing mechanism 7, start the rotating mechanism 6 to drive the fixing mechanism 7 Clamp it while the petri dish rotates, when the fixing mech...

Embodiment 2

[0048] On the basis of Example 1, such as image 3 and Figure 4 As shown, the rotating mechanism 6 includes a motor 61, a missing gear 62, a rotating shaft 63, a first gear 64, a first runner 65 and a belt 66, the left side of the bottom plate 1 is provided with a motor 61, and the output shaft of the motor 61 is provided with Missing gear 62, bottom plate 1 top rear side is symmetrically rotated and is provided with rotating shaft 63, and the bottom of left rotating shaft 63 is provided with first gear 64, and first gear 64 cooperates with missing gear 62, and rotating shaft 63 top is provided with first runner 65, a belt 66 is connected between the first runners 65.

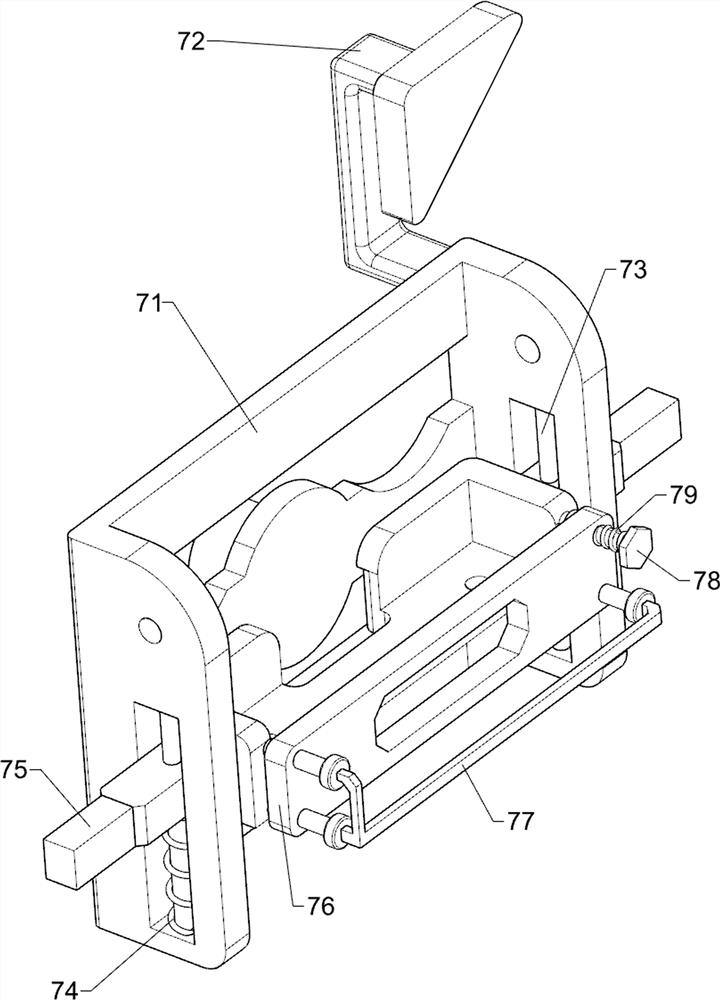

[0049] Fixed mechanism 7 comprises fixed frame 71, inclined bar 72, first guide rod 73, second spring 74, storage groove 75, clip block 76, first handle 77, fixing nail 78 and the 3rd spring 79, belt 66 outsides are uniformly arranged There are 4 fixed mounts 71, the top of the fixed mount 71 is provided wit...

Embodiment 3

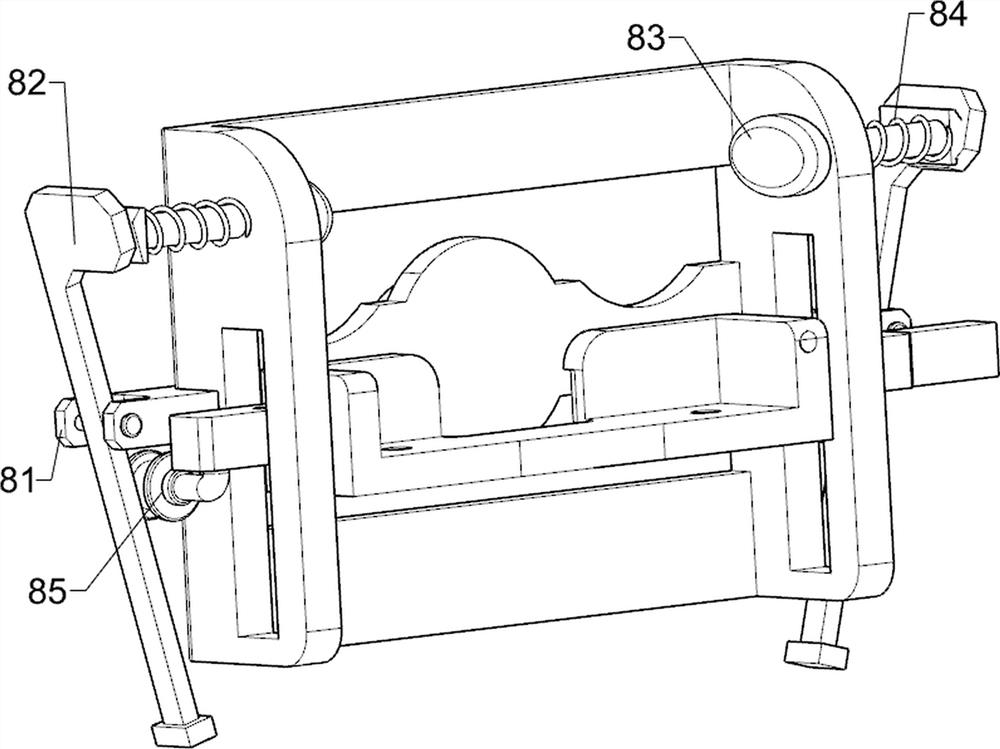

[0052] On the basis of Example 2, such as Figure 5 to Figure 8 As shown, loosening mechanism 9 is also included, and loosening mechanism 9 includes second runner 91, toothed belt 92, second fixed block 93, second gear 94 and rotating rod 95, and fixed mount 71 bottom outer sides are all provided with 2 A second fixed block 93, between the second fixed block 93 and the fixed frame 71 is connected with a rotating rod 95 in a rotational manner, the bottom of the rotating rod 95 is provided with a second gear 94, the second gears 94 mesh with each other, and the middle part of the rotating shaft 63 is provided with a second gear 94. The second rotating wheel 91 is connected with a toothed belt 92 between the second rotating wheel 91 , and the toothed belt 92 cooperates with the second gear 94 .

[0053] The staff can align the culture dish with the rotating rod 95 for placement, the rotating shaft 63 rotates through the second rotating wheel 91 to drive the toothed belt 92 to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com