Liquid crystal display panel and manufacturing method thereof

A technology for liquid crystal display panels and manufacturing methods, applied in nonlinear optics, instruments, optics, etc., can solve the problems of uneven thickness of liquid crystal display panels, poor conduction effect, mula, etc., and achieve the effect of improving the quality of picture display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced.

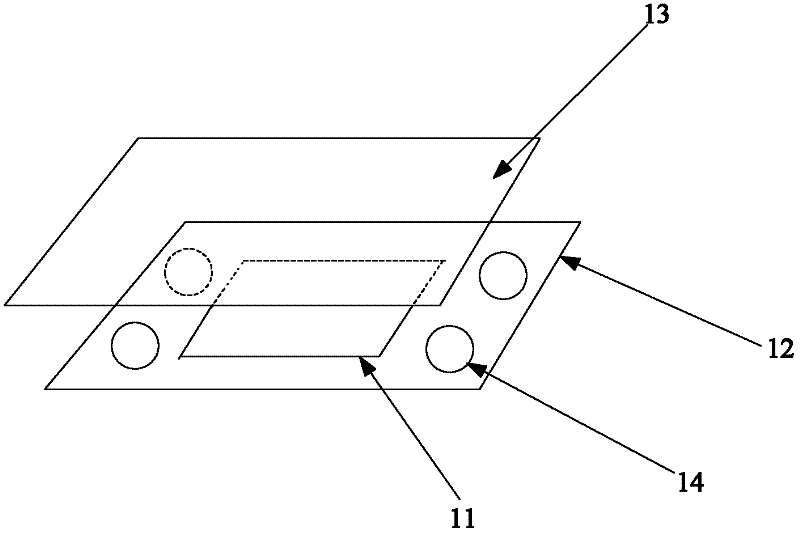

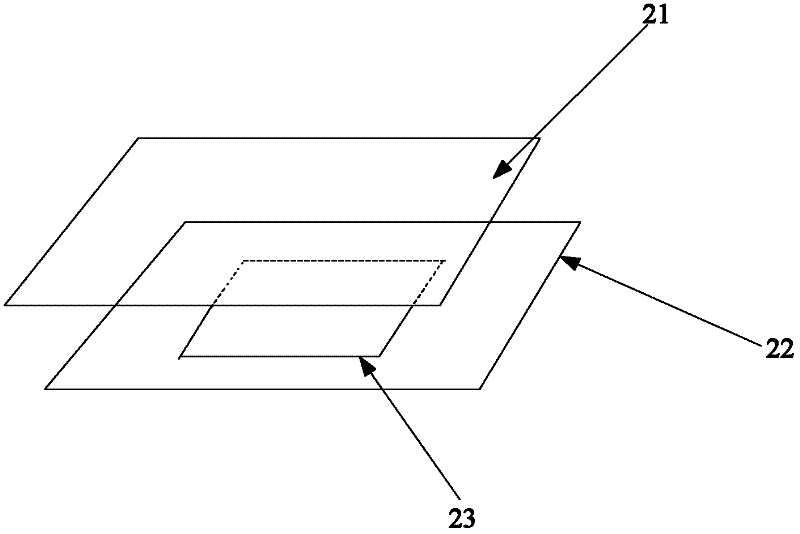

[0034] see figure 2 , figure 2 It is a structural diagram of a preferred embodiment of a liquid crystal display panel in the present invention.

[0035] The liquid crystal display panel includes a color filter substrate 21 and an array substrate 22 , and also includes a conductive sealant 23 , wherein the color filter substrate 21 and the array substrate 22 are bonded by the conductive sealant 23 .

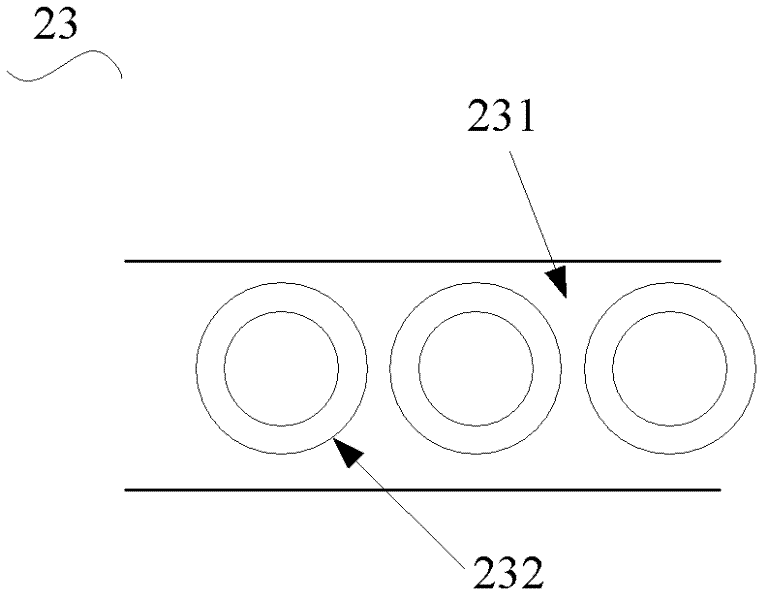

[0036] see image 3 , image 3 for figure 2 A structural diagram of a preferred embodiment of the conductive sealant 23 described in .

[0037] The conductive sealant 23 includes a sealant 231 and conductive particles 232 , wherein the conductive particles 232 are uniformly dispersed in the sealant 231 .

[0038] see Figure 4 , Figure 4 for image 3 A structural diagram of a preferred emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com