Color filter and color filter manufacturing method

一种彩色滤光片、制造方法的技术,应用在彩色滤光片领域,能够解决不能基板与相对基板间隔保持均匀等问题,达到显示质量高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

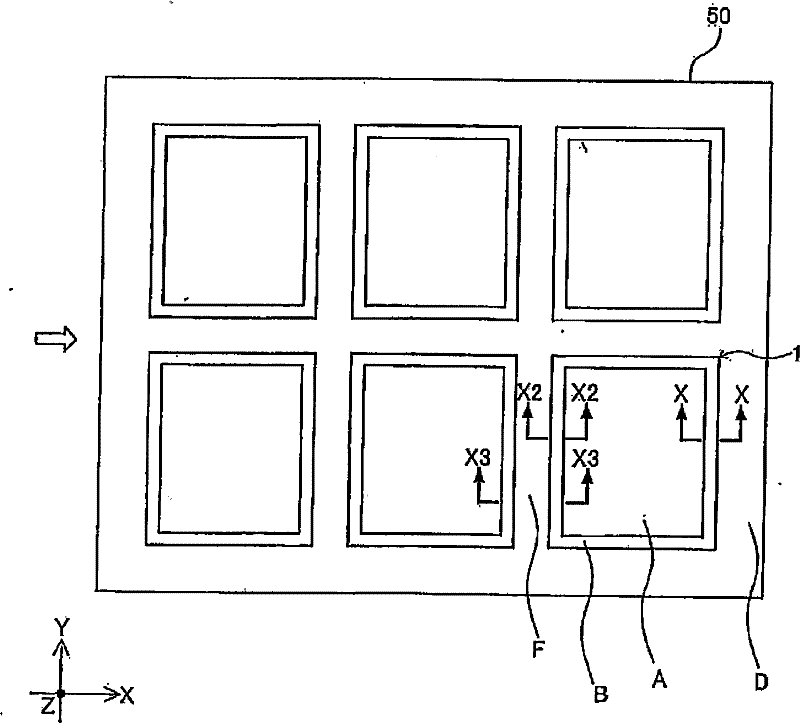

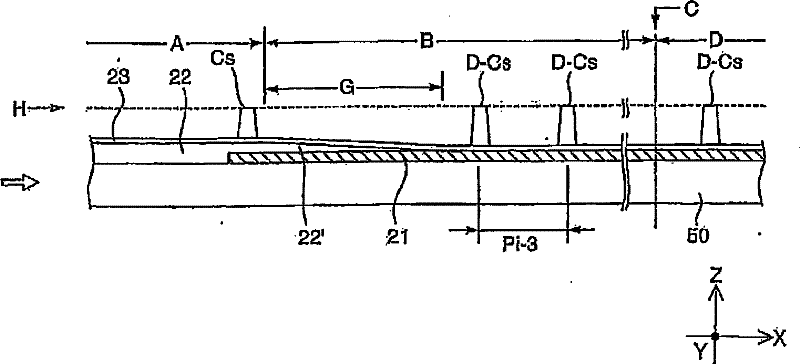

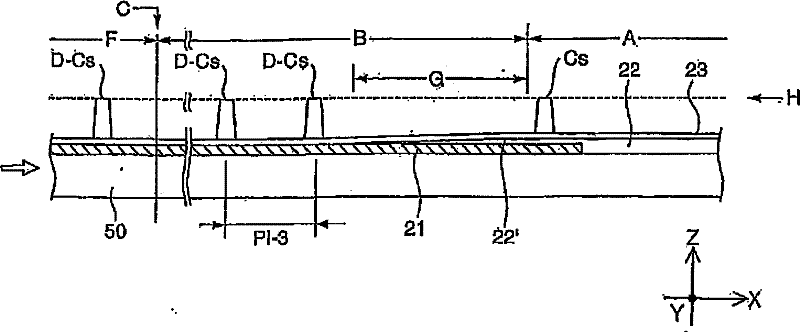

[0079] figure 1 It is a plan view showing an example of a color filter according to the first embodiment of the present invention formed on a substrate, figure 2 yes figure 1 The cross-sectional view along the X-X line of the substrate shown, image 3 yes figure 1 A cross-sectional view of the substrate along line X2-X2 is shown. In addition, in the following description, the direction in which a board|substrate is conveyed at the time of manufacture is made into the X-axis direction.

[0080] figure 1 Six (2 rows×3 rows) of color filters 1 are formed on the substrate 50 shown. In the color filter 1, a plurality of pixels arranged in the X-axis direction and the Y-axis direction are formed. The color filter 1 includes a substrate 50 , a black matrix 21 , a stripe pattern 22 , a plurality of columnar spacers Cs, and a plurality of dummy columnar spacers D-Cs.

[0081] The black matrix 21 is a light-shielding layer that divides a rectangular display portion A (corres...

no. 2 approach

[0098] Figure 5 It is a partial cross-sectional view of the color filter of the second embodiment. also, Figure 5 shows the equivalent of figure 1 Shown is a portion of the cross-section of the substrate along line X-X. Since the manufacturing method of the color filter of this embodiment is the same as that of the first embodiment, repeated description is omitted.

[0099] As described above, the length (X-axis direction) of the stripe pattern 22 formed on the frame portion B varies. The greater the length of the stripe pattern 22 formed on the frame portion B, the greater the external force applied to the dummy columnar spacers D-Cs when the substrate 50 is bonded to the counter substrate. Therefore, it is preferable to change the arrangement density of the pseudo columnar spacers (the number of pseudo columnar spacers formed per unit area) according to the length of the stripe pattern 22 formed on the frame portion B.

[0100] formed in Figure 5 The length G2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com