Tobacco harvesting machine with turntable slider mechanism

A harvester and turntable technology, applied in the field of tobacco harvesters, can solve the problems of complex structure, large labor and time consumption, high production cost, and achieve the effects of high harvesting efficiency, high picking rate and uniform beating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

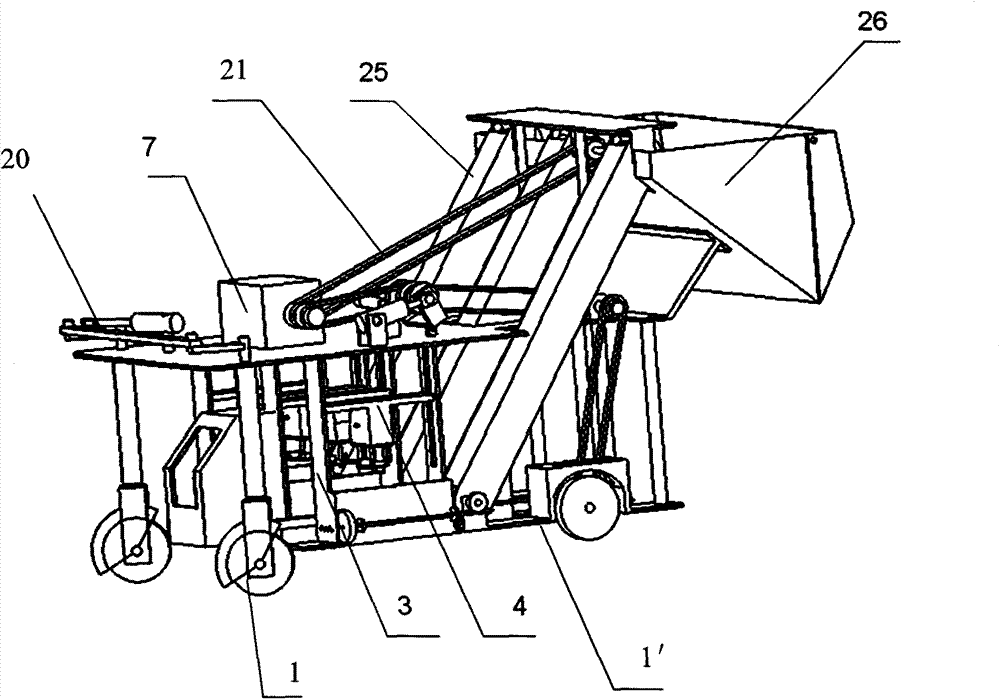

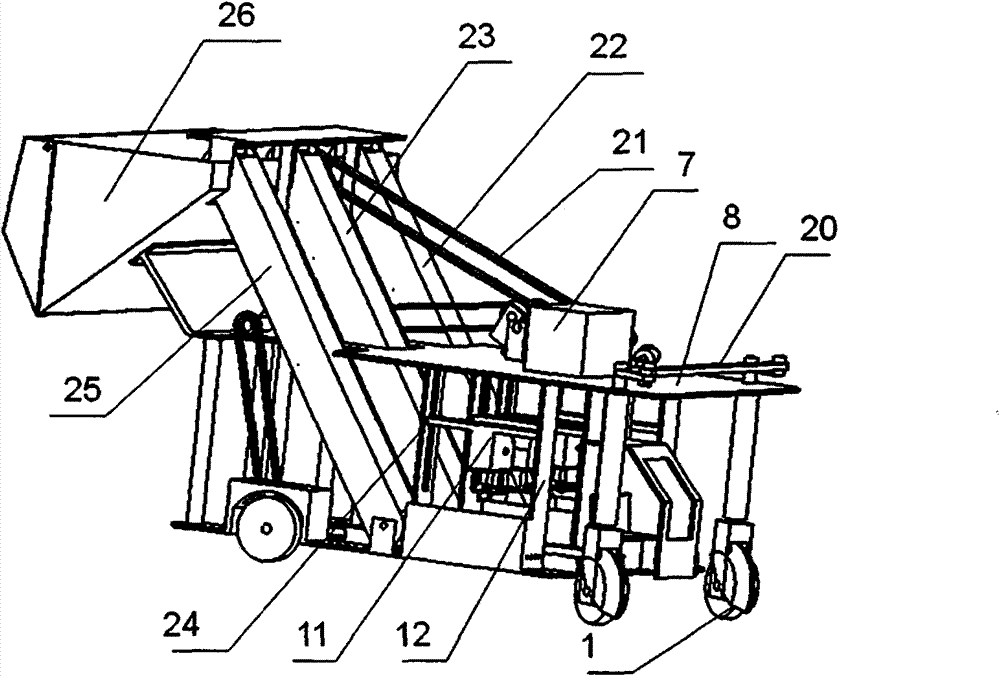

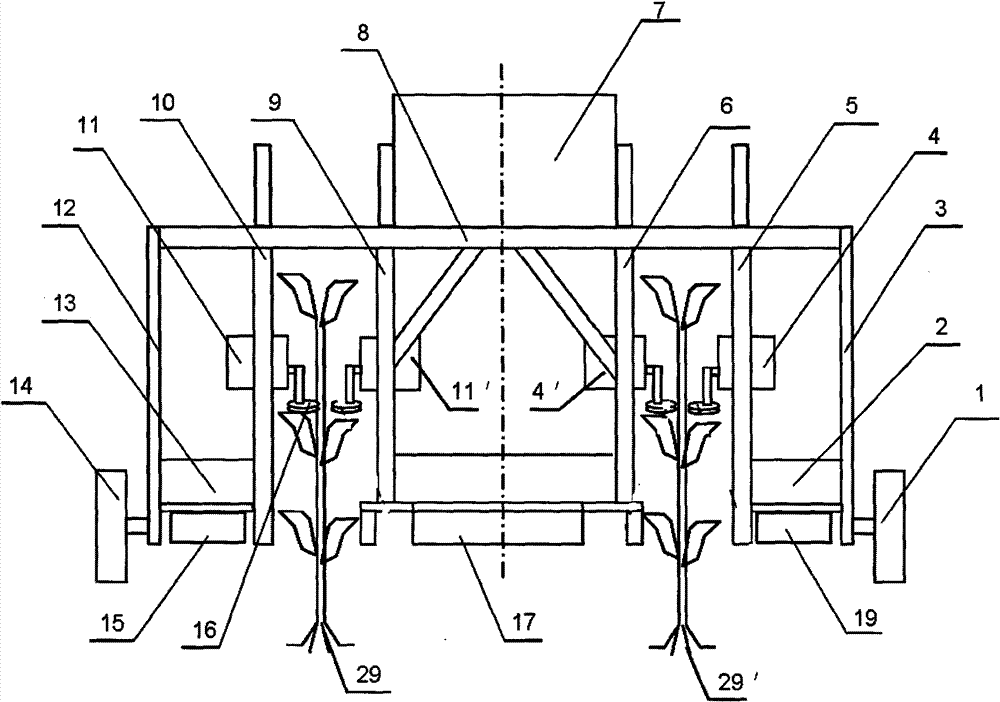

[0017] Such as Figure 1~3 The shown tobacco harvester includes a vehicle frame and a driving part. The vehicle frame includes a main frame top plate 8, a left bottom leaf box baffle 13 and a right bottom leaf box baffle 2, and the main frame top plate 8 and the left side The bottom leaf box baffle plate 13 and the right bottom leaf box baffle plate 2 are connected by several vehicle frame frames. Engine 7 and tobacco leaf collection box 26 are housed on the main frame top plate 8, left main conveyer belt 25 is housed between left side bottom leaf box baffle plate 13 and tobacco leaf collection box 26, right bottom leaf box baffle plate 2 and tobacco leaf collection The right side main conveyor belt 22 is housed between the boxes 26 . The main conveyor belt 25 on the left side, the main conveyor belt 22 on the right side, and the main conveyor belt 23 in the middle are connected to the engine 7 through the conveyor belt input system 21 . The vehicle frame is divided into thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com