Vacuum moving device and method

A technology of vacuum movement and vacuum chamber, which is applied in the field of vacuum movement and vacuum movement devices, can solve the problems of high cost, limited movement mode, complex design, etc., and achieve the effect of low driving cost, reduced implementation cost and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

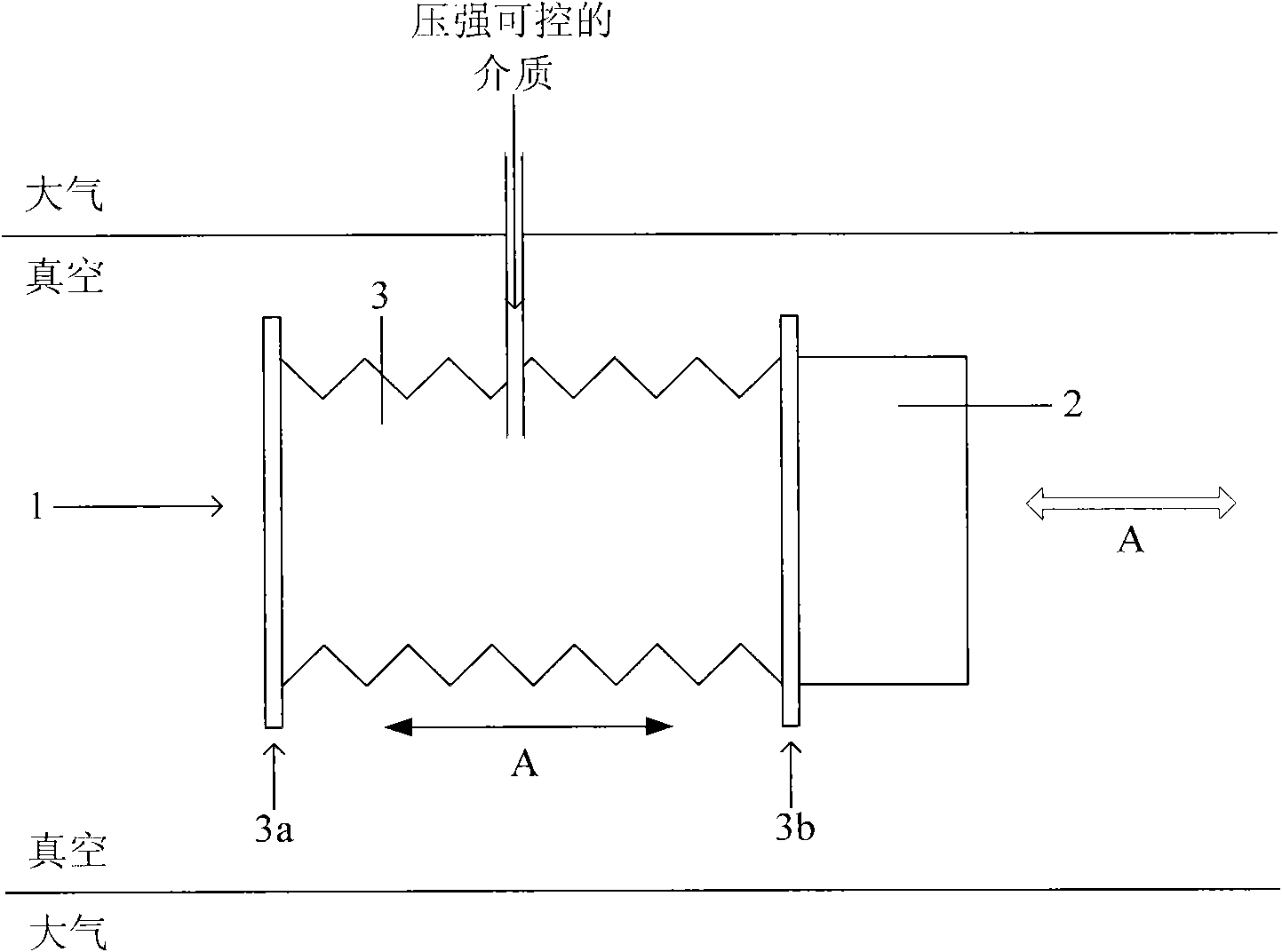

[0027] Such as figure 2 As shown, in this embodiment, a bellows 3 is used to realize the translation of the moving object 2 . By adjusting the pressure of the medium in the bellows 3, the bellows 3 reciprocates and expands in the direction shown by the arrow A, and the fixed end 3a of the bellows 3 is fixed, so the bellows 3 The moving end 3b of the moving object 2 will drive the moving object 2 to move back and forth along the direction indicated by the arrow A.

Embodiment 2

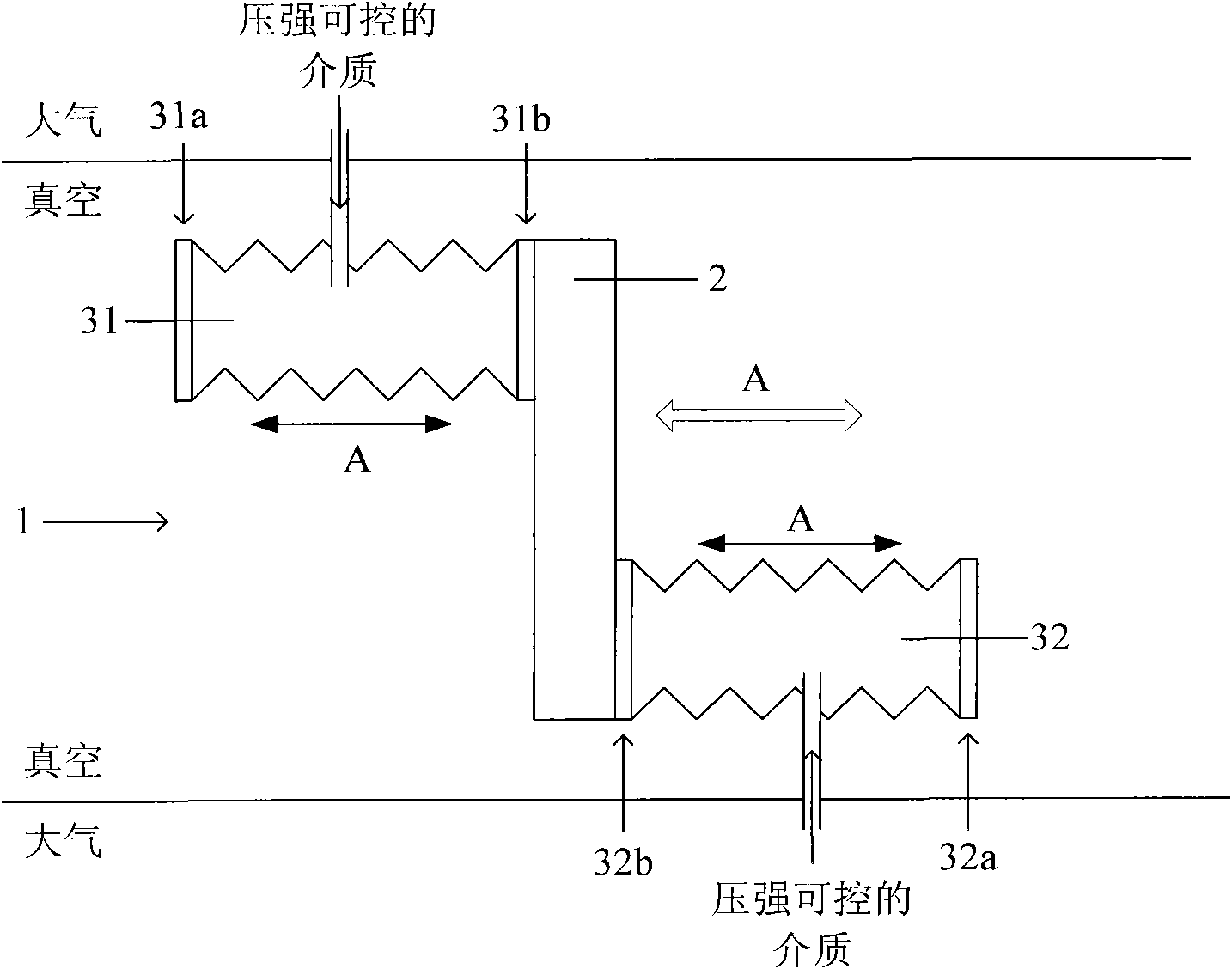

[0029] Such as image 3 As shown, in this embodiment, two bellows 31 , 32 are used to realize the translation of the moving object 2 . By adjusting the pressure of the medium inside the two bellows 31, 32, the bellows 31 shrinks along the direction shown by the arrow A, while the bellows 32 elongates along the direction shown by the arrow A, or The corrugated tube 31 is elongated along the direction shown by arrow A, while the corrugated tube 32 is shrunk along the direction shown by arrow A, and the fixed ends 31a, 32a of the corrugated tubes 31, 32 are fixed. , so the moving ends 31b, 32b of the two bellows 31, 32 will drive the moving object 2 to reciprocate along the direction indicated by the arrow A.

[0030] The method of realizing the translation of the moving object 2 by using multiple bellows is completely the same as the realization principle of this embodiment, so it will not be repeated here.

Embodiment 3

[0032] Such as Figure 4 As shown, in this embodiment, a bellows 3 is used to realize the rotation of the moving object 2, wherein the rotation axis O of the moving object 2 is perpendicular to the paper surface, and the expansion and contraction direction of the bellows 3 does not pass through the rotation Axis O. By adjusting the pressure of the medium in the bellows 3, the bellows 3 reciprocates and expands in the direction shown by the arrow A, and the fixed end 3a of the bellows 3 is fixed, so the bellows 3 The moving end 3b of the moving object 2 will drive the moving object 2 to reciprocate and rotate around the rotation axis O along the direction indicated by the arrow B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com