Two-layer manual liner anti-seepage structure for storage tank foundation and construction method for two-layer manual liner anti-seepage structure

A storage tank foundation and artificial technology, applied in infrastructure engineering, protective devices, buildings, etc., can solve the problems of limited discharge capacity of oil-water mixture, economic loss, easy fire, etc., to avoid environmental pollution and economic loss, increase The effect of a large safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

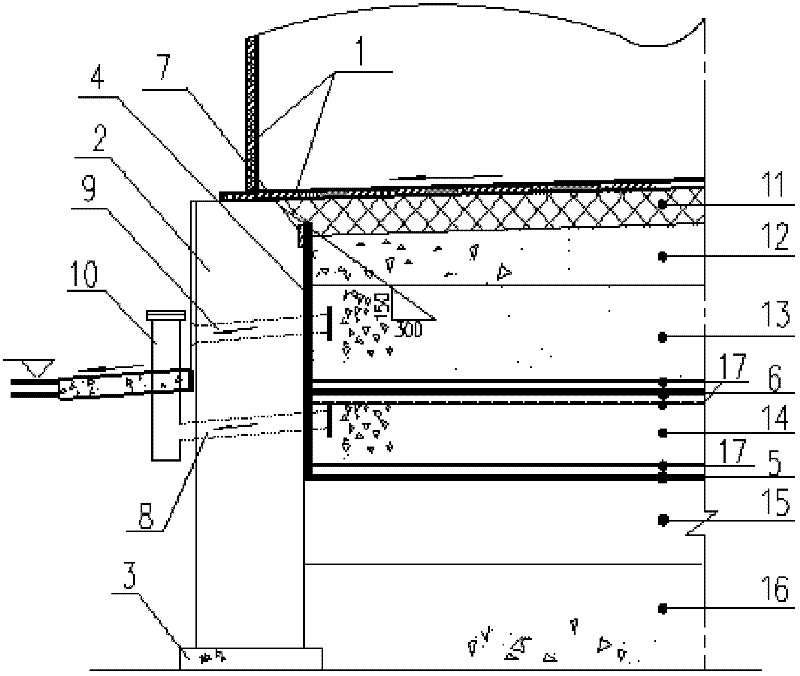

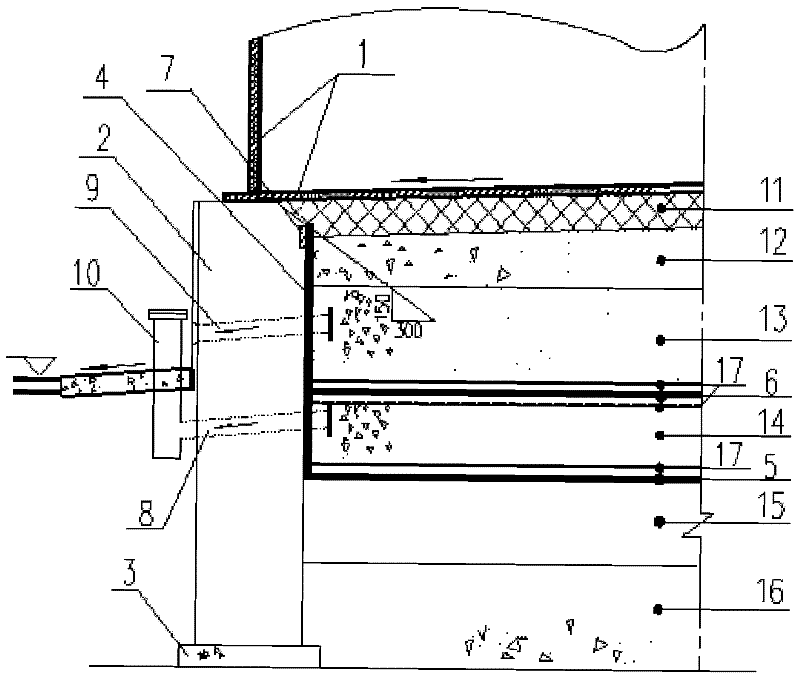

[0024] Embodiment 1: Taking the construction method of a double-layer artificial lining anti-seepage structure of a storage tank foundation as an example, the present invention is further described in detail.

[0025] refer to figure 1 . A double-layer artificial lining anti-seepage structure for a storage tank foundation, including a circular ring beam, a ring beam foundation cushion, and an inner cushion of the ring beam; and an anti-seepage membrane embedded in the storage tank ring beam 2 In the internal pad, the anti-seepage membrane includes a vertical anti-seepage membrane 4, a first layer of horizontal anti-seepage membrane 5 and a second layer of horizontal anti-seepage membrane 6, the vertical anti-seepage membrane 4, the first layer of horizontal anti-seepage Membrane 5 and the second layer of horizontal anti-seepage membrane 6 are connected as a whole, vertical anti-seepage membrane 4 runs along the inner surface of the upper part of ring beam 2 to the top of ring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com