Lower cover structure of closed type compressor

A compressor, airtight technology, applied in the field of compressors, can solve problems such as waste of raw materials and increase in product cost, and achieve the effects of extending the reflection path, improving stiffness and strength, and increasing the reflection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, the structure of the lower cover of the hermetic compressor of the present invention will be described in detail with reference to the accompanying drawings and embodiments:

[0034] Parts and accessories of the present invention are identical with those of the prior art and adopt the same reference numerals.

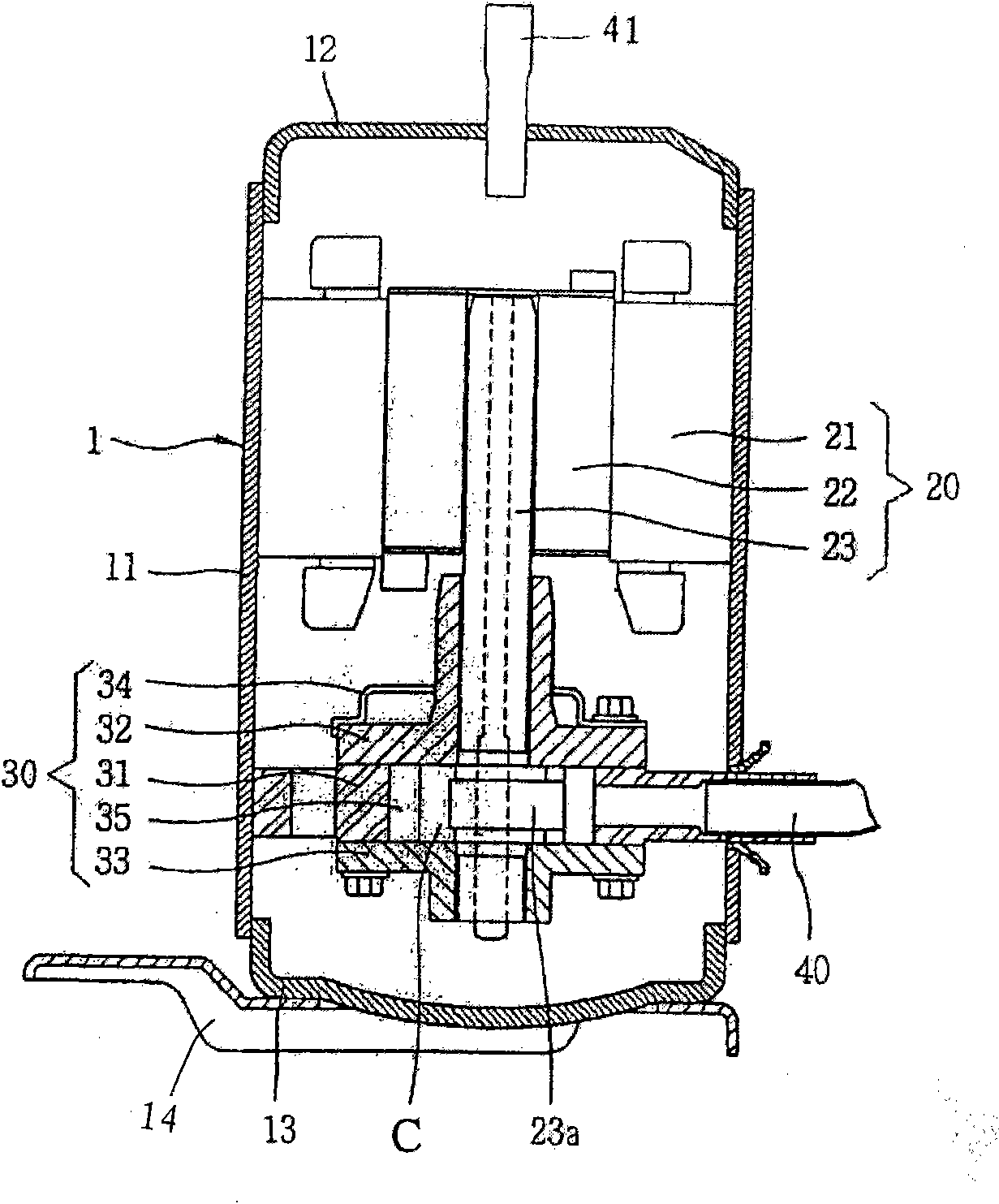

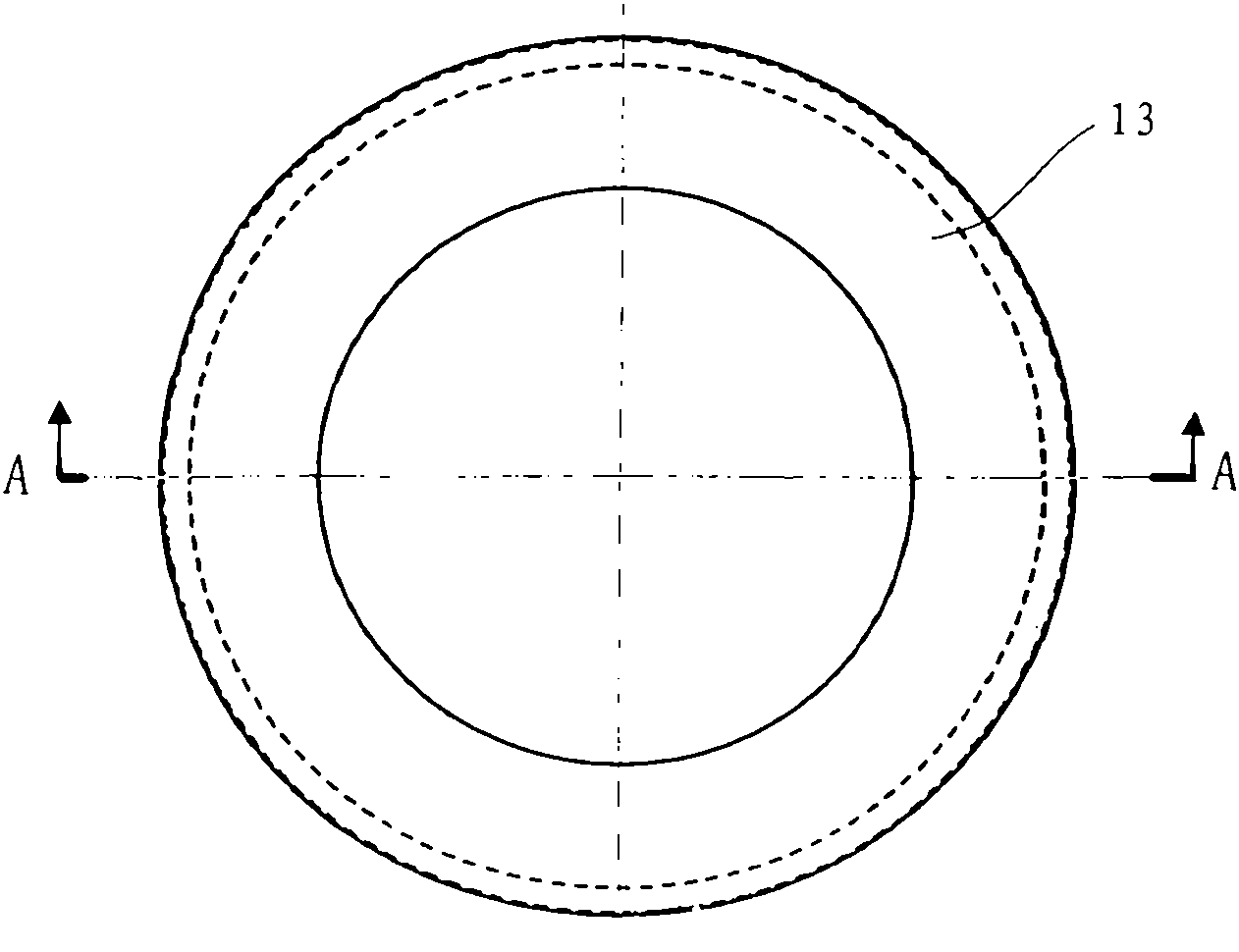

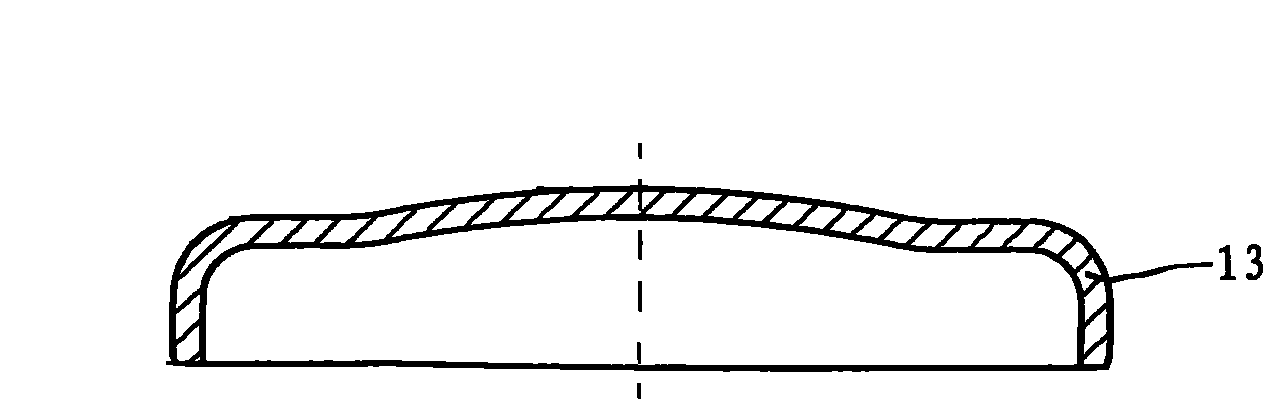

[0035] Such as Figure 4~6 As shown, a hermetic compressor lower cover structure includes a housing 1, a motor assembly 20 is installed on the inner upper side of the housing 1, and a compressor assembly 30 is installed on the lower side of the motor assembly 20 at a certain distance. The casing 1 is composed of a hollow cylindrical body 11 , an upper cover 12 and a lower cover 15 , and the lower cover 15 is installed on a base 14 .

[0036] A plurality of continuous protruding rings 16 and concave rings 17 are formed on the lower cover 15 . In the present invention, there are two protruding rings and one concave ring. A sound-absorbing cavity 18 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com