Magnetic memory based tightness detection method for flange and detection device and detection system thereof

A flange sealing and detection method technology, applied in detection devices and detection systems, in the field of flange sealing detection based on magnetic memory, can solve the problems of large influence on detection accuracy, low efficiency of flange sealing, and large influence of ambient temperature and other problems, to achieve the effect of avoiding economic loss, stable operation and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

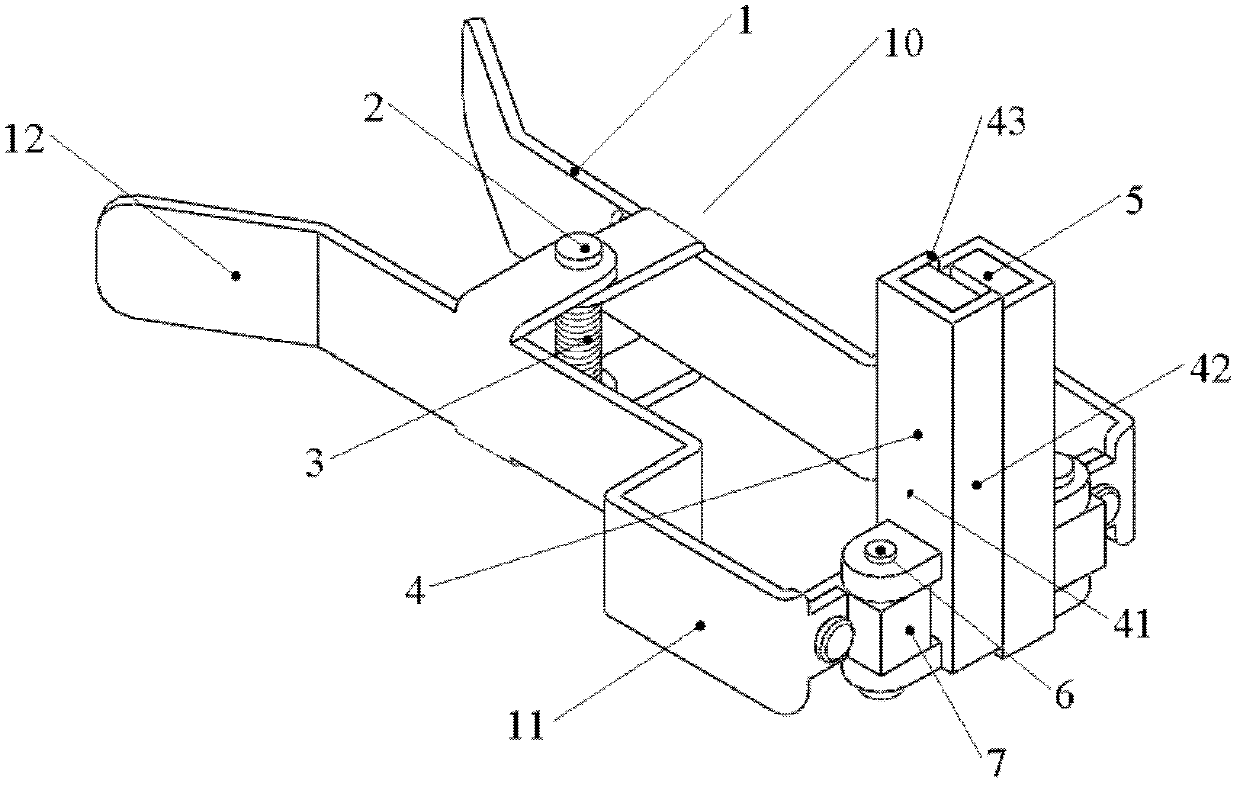

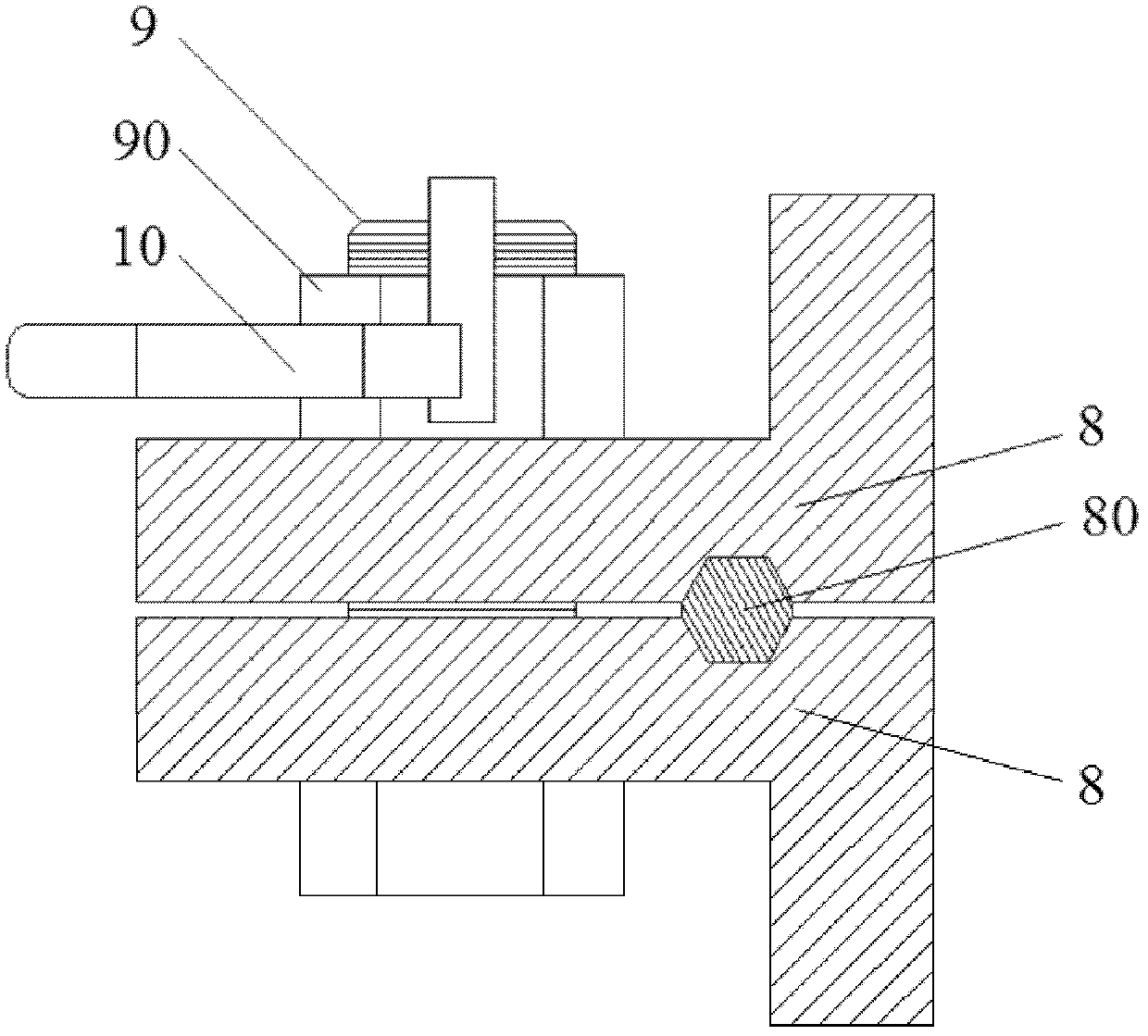

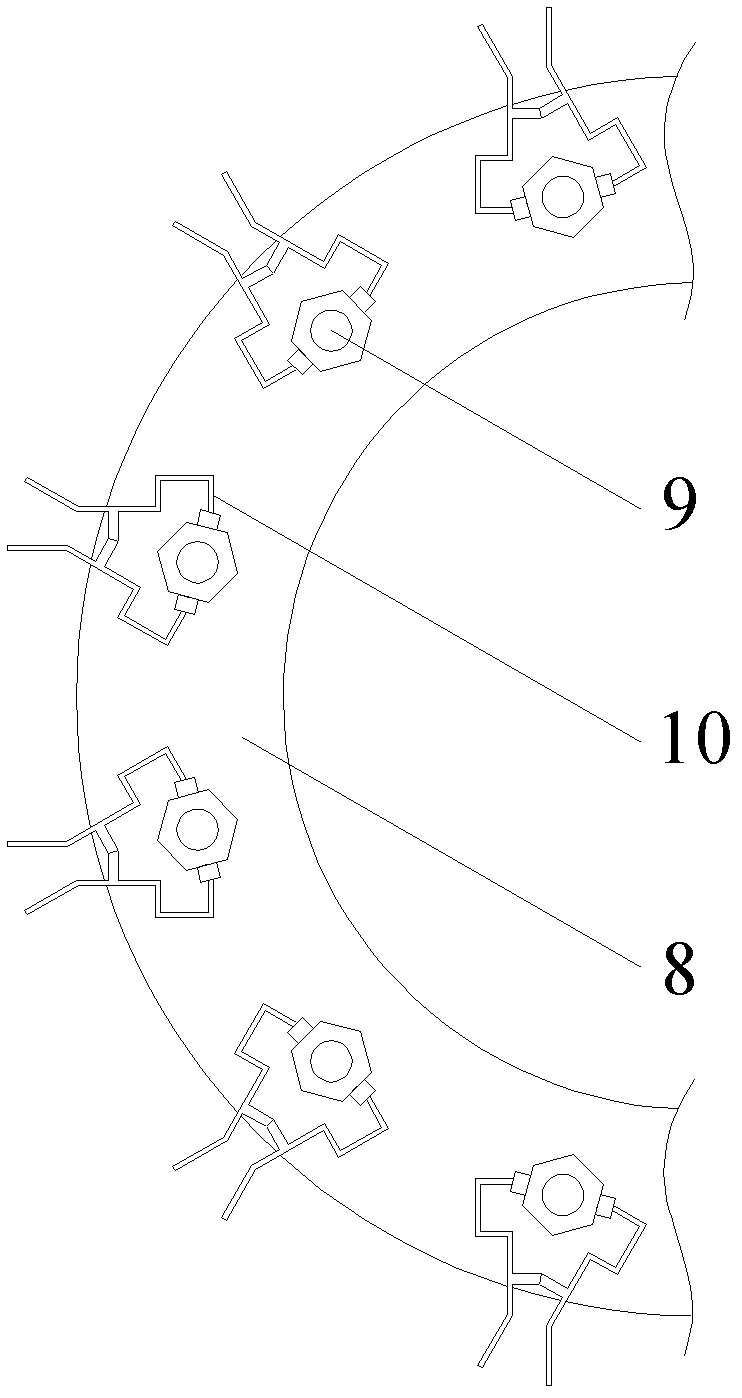

[0050] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation methods, detection devices and detection systems of the magnetic memory-based flange tightness detection method, detection device and detection system of the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. The structure, characteristics and functions are described in detail below. In addition, through the description of the specific implementation, the technical means and effects of the present invention to achieve the intended purpose can be understood more deeply and specifically. However, the attached drawings are only for reference and illustration, and are not used to limit the present invention. .

[0051] A kind of flange tightness detection method based on magnetic memory that the present invention proposes comprises:

[0052] A. Calibrate the magnetic me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com