Method for monitoring wind turbines

A technology of wind turbines and control units, applied in the direction of wind engines, wind motor combinations, wind turbine components, etc., which can solve problems such as expensive, vulnerable to failures, computers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

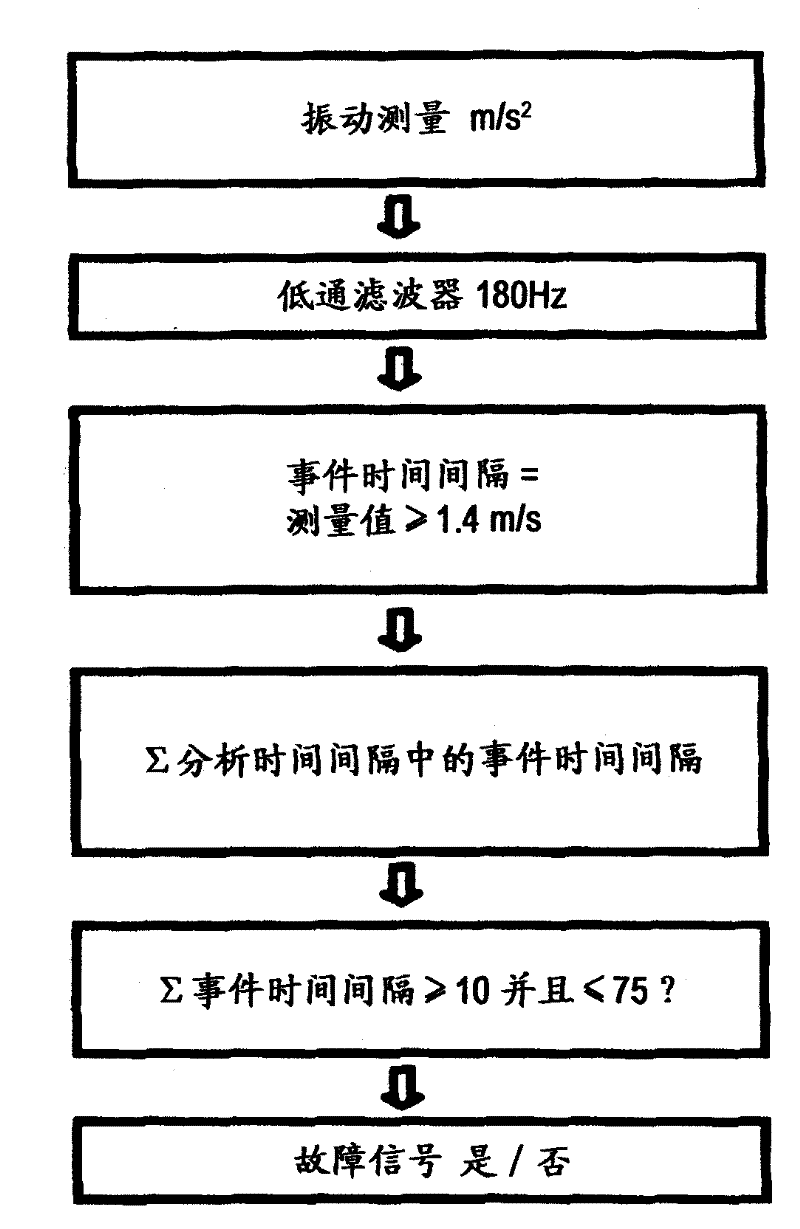

[0058] exist figure 1 In , the necessary steps of the method according to the invention for monitoring a wind turbine 3 are described. In order to be able to check each individual rotor blade of the wind turbine 3 for possible rotor blade damage, the wind turbine 3 is equipped with at least one acceleration sensor 10 which measures the vibrations of the individual rotor blades with a sampling frequency of at least 10 kHz. Next, the measurement results are introduced through a 180Hz low-pass filter.

[0059] Acquisition in which the measured value is always over 1.4m / s 2 The time interval of is used as the event time interval. During the 5 min analysis time interval, count event time intervals. If the number of event time intervals in the evaluation time interval corresponds to a value between 10 and 75, a fault signal is output.

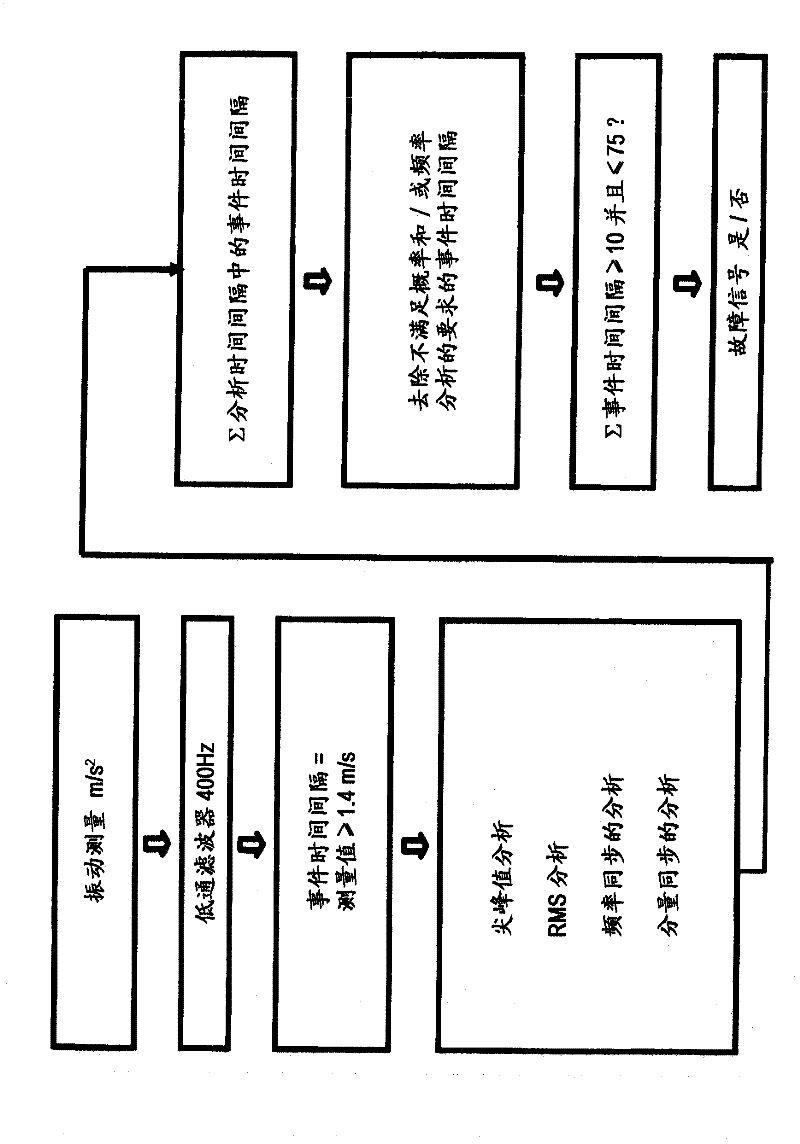

[0060] figure 2 An expanded embodiment of the method according to the invention is shown which, in addition to the analysis step in the time d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com