Hydrodynamic foil bearing assembly

A technology for foil bearings, bearing assemblies, applied in the direction of bearing elements, bearings, shafts and bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Various embodiments are described with reference to the drawings, wherein like reference numerals are used to refer to like elements throughout. In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It is apparent that the embodiments may be practiced without these specific details.

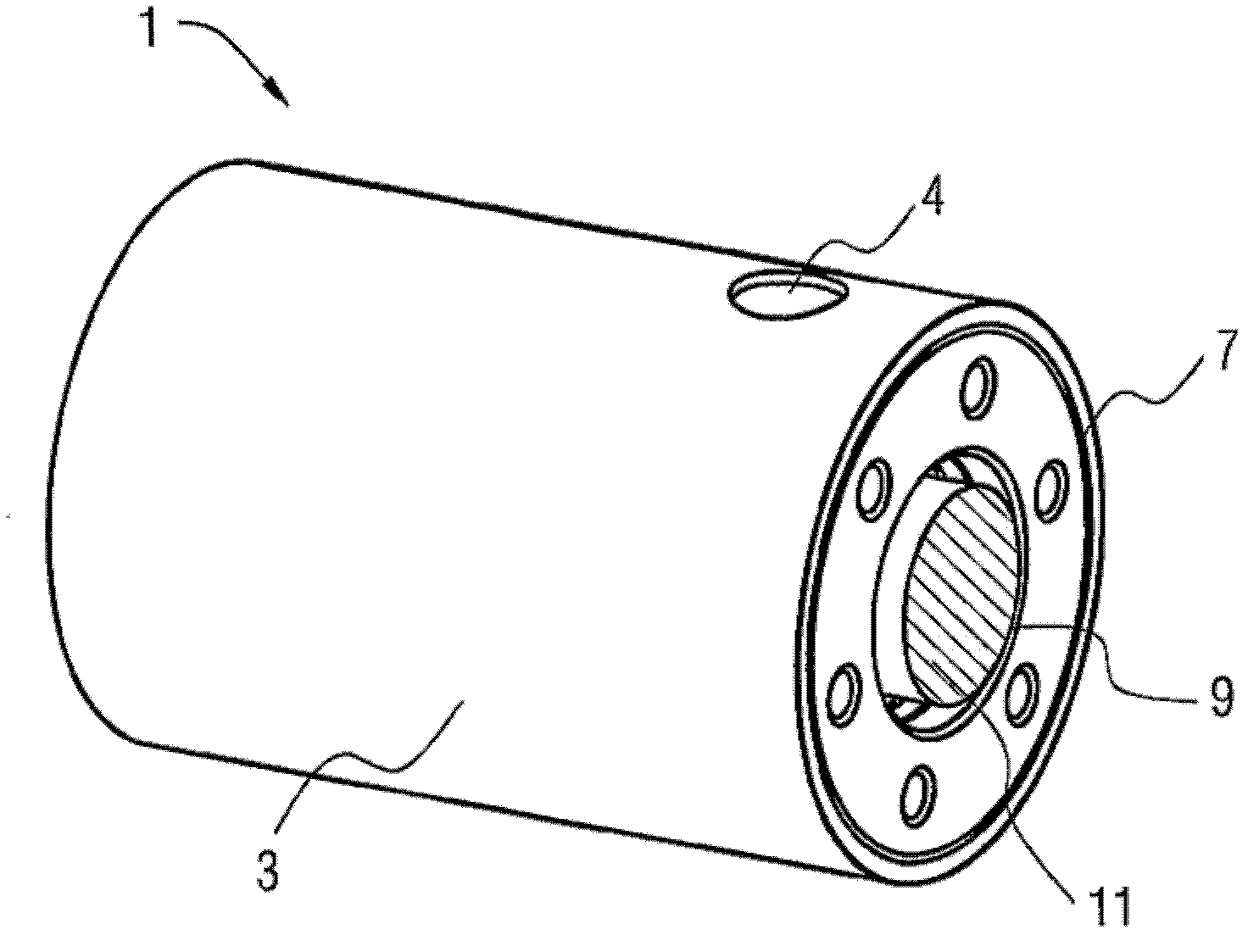

[0043] figure 1 A perspective view of a hydrodynamic foil bearing assembly according to embodiments herein is shown. The hydrodynamic foil bearing assembly 1 comprises a bearing housing 3 and an opening 4 . The bearing housing 3 typically comprises a cylindrical hollow section and at least one foil (not shown) delimiting the cylindrical hollow space for receiving the rotating shaft 11 arranged inside the bearing housing 1 . A gap is defined between the inner wall surface of at least one foil and the outer circumference of the rotating shaft 11 .

[0044] In one embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com