Anti-swirling method

A technology of anti-rotation and production methods, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

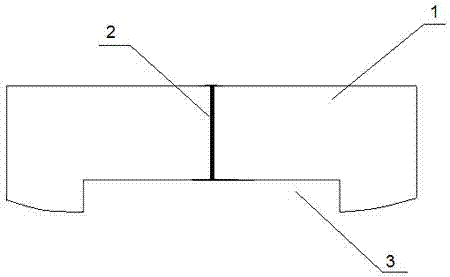

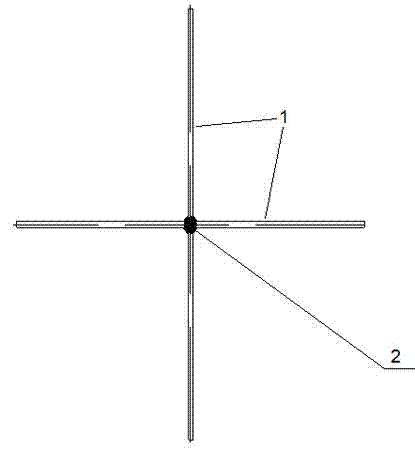

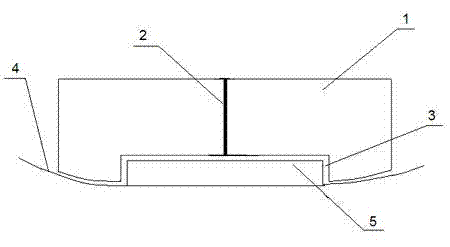

[0019] refer to figure 1 ,and figure 2 , in the anti-swirl method of the present invention, the preparation method of the anti-swirl plate is as follows:

[0020] Connect one end of each baffle plate 1 to different directions of the same vertical shaft 2, and make it radially arranged vertically; one end of the baffle plate 1 connected to the vertical shaft 2 forms a fixed end, and the other end forms a near kettle end.

[0021] Make the end near the reactor of multiple baffles into an arc shape that matches the inner wall 4 of the reactor, and make the lower side of the baffle 1 higher than the bottom end of the arc near the end of the reactor to form a gap between the bottom side of the baffle 1 and the outlet of the reactor. 5 to match the notch 3.

[0022] The number and height of the baffles 1 can be adjusted according to the volume of the reactor, wherein the number of baffles is preferably 3-16, and the height of the baffles is preferably 5-200 cm.

[0023] refer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com