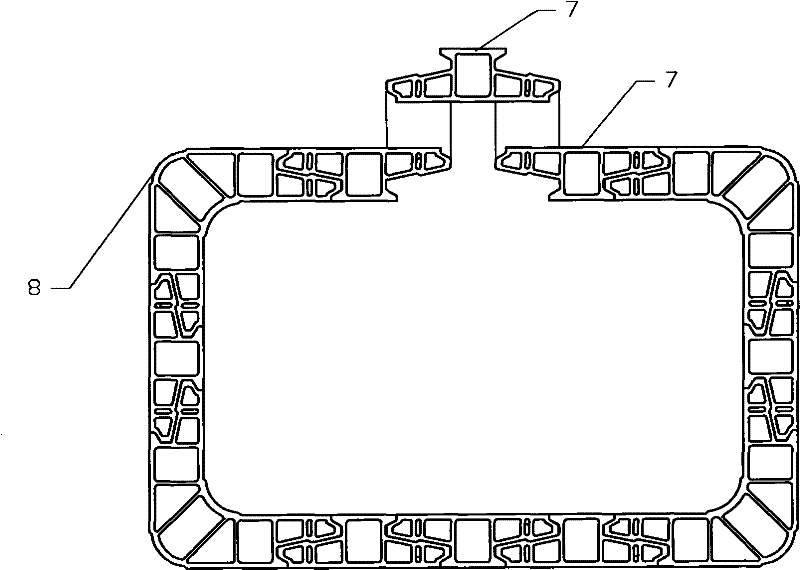

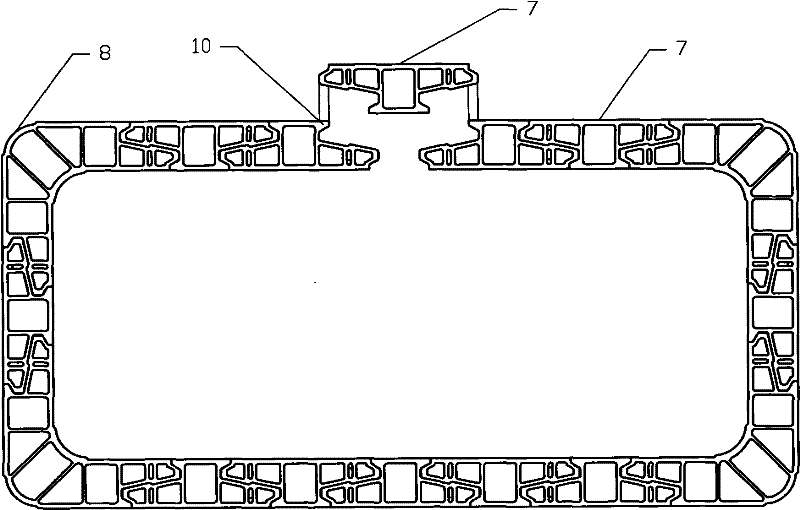

Closed combination template

A technology of combining formwork and formwork, which is applied in the field preparation and construction of formwork/formwork components and building components, can solve the problems of sealing of pouring formwork, etc., and achieve the effect of convenient operation, convenient operation, labor saving and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

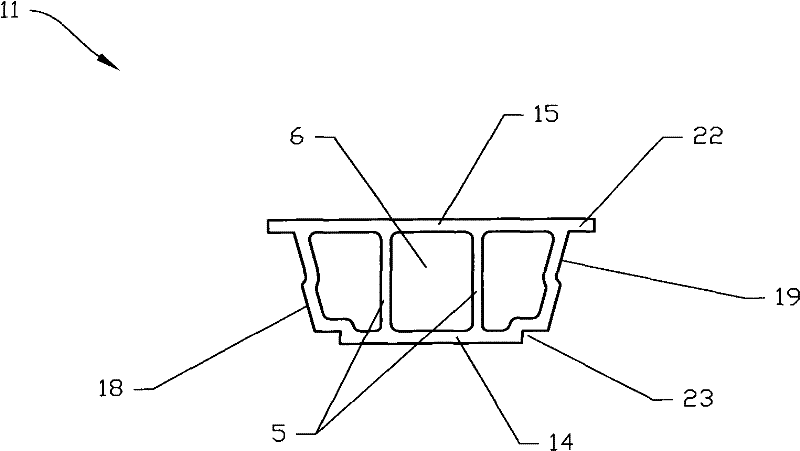

[0040]At first, the related concepts involved in the present invention are defined as follows:

[0041] The front panel of the closed formwork refers to the panel on the closed formwork that is first close to the connected formwork when the connection formwork and the closed formwork undergo relative displacement during the assembly process of the connection formwork and the closed formwork.

[0042] The closed template rear panel refers to the relative displacement of the connected template and the closed template during the assembly process of the connected template and the closed template, and the last panel on the closed template is close to the connected template; The closed template rear panel is opposite to the closed template front panel.

[0043] The front panel of the connecting form means that during the assembling process of the connecting form and the closed form, the relative displacement of the connecting form and the closed form occurs, and the first panel on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com