Force releasing mechanism and ratchet wheel clamp with same

A ratchet and ratchet technology, which is applied in the field of ratchet clips, can solve the problems of laborious and difficult operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

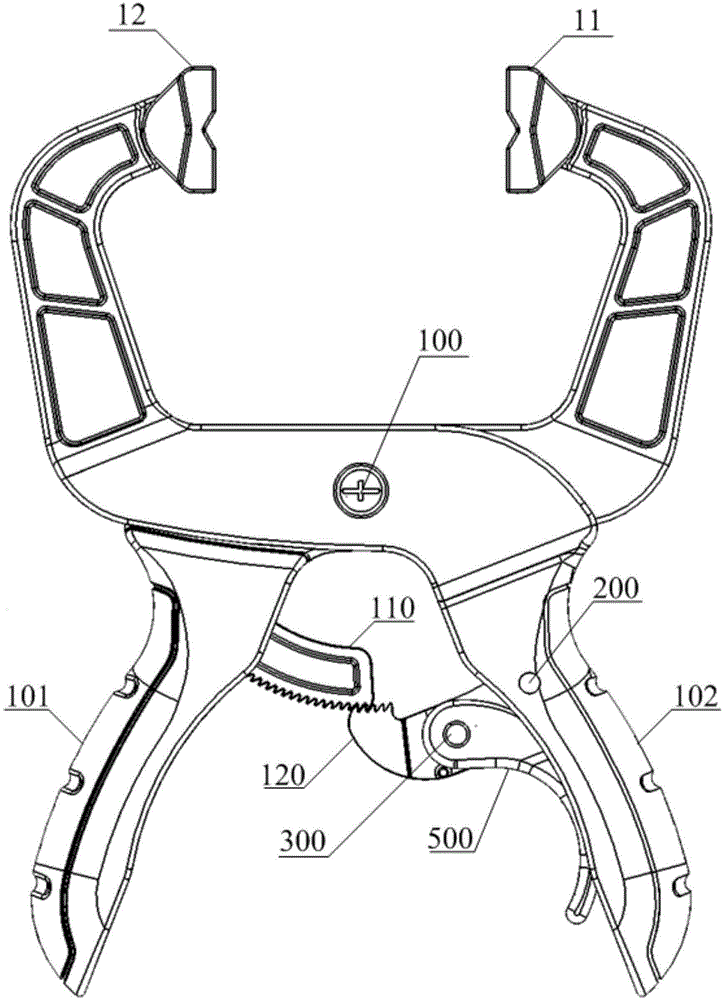

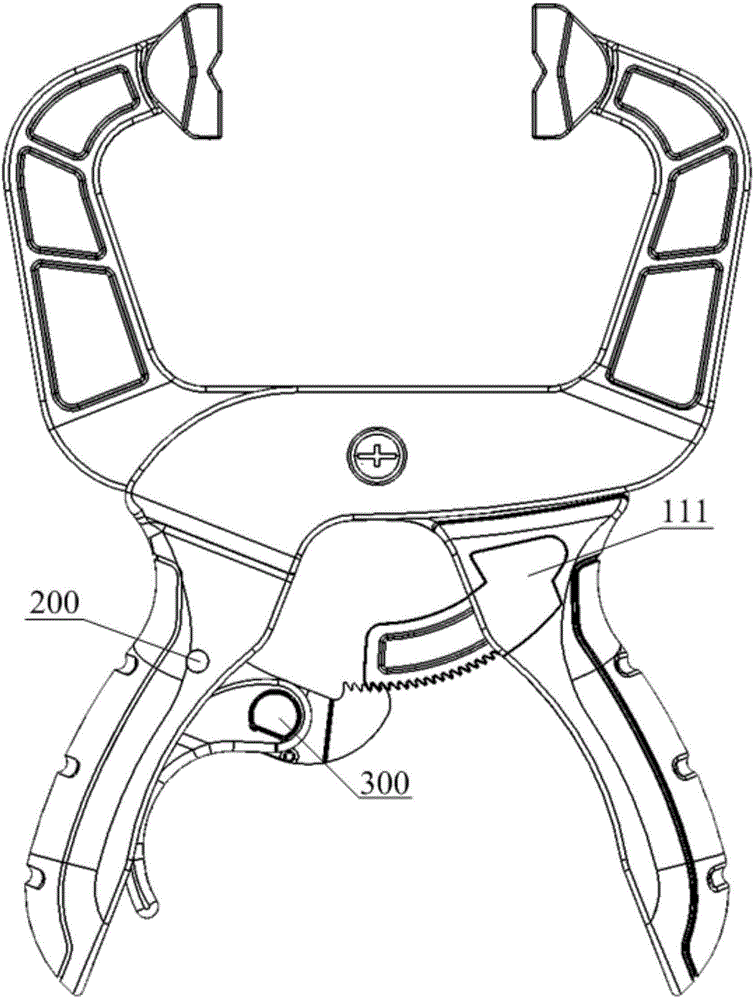

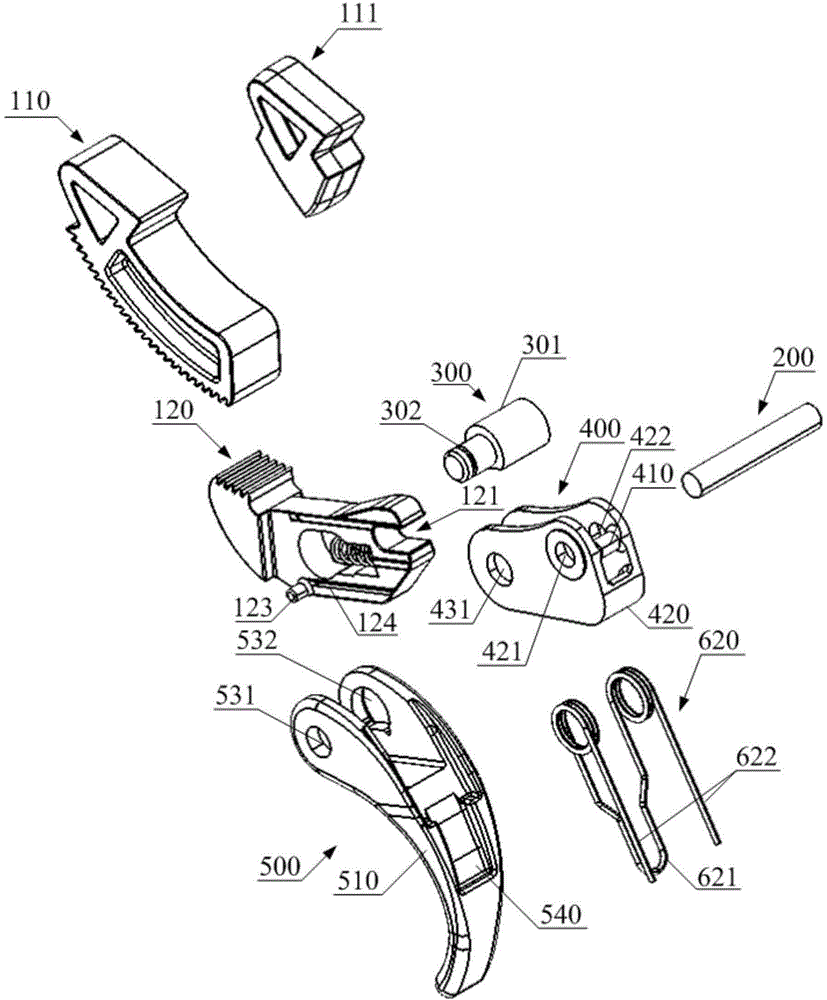

[0058] figure 1 and 2 Shown in a preferred embodiment of the present invention has a ratchet clamp with force relief mechanism, its first clamp arm 101 and second clamp arm 102 are connected by a first shaft 100, and can rotate around the first shaft 100 to control Closing or opening of the first jaw part 11 and the second jaw part 12 . Specifically, when the user applies a force to the first clamp arm 101 and the second clamp arm 102 to make them approach each other (that is, the first clamp arm 101 and the second clamp arm 102 move toward each other), the first jaw portion 11 and the second clamp arm 102 will move toward each other. The second jaw portion 12 is also close to each other, thereby clamping an object such as a workpiece; When the jaw arm 102 moves away from each other), the first jaw part 11 and the second jaw part 12 also move away from each other, thereby releasing the workpiece.

[0059] A force relief mechanism is arranged between the first clamping arm 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com