Anesthesia machine and respirator proportion valve flow pushing and fondling control method

A proportional valve, ventilator technology, applied in the direction of using electric device flow control, respirator, electric controller, etc., can solve the problems of feedback cycle influence, cumbersome adjustment method, unfavorable large-scale production and maintenance, etc., to achieve rapid adjustment, The effect of solving the overshoot phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

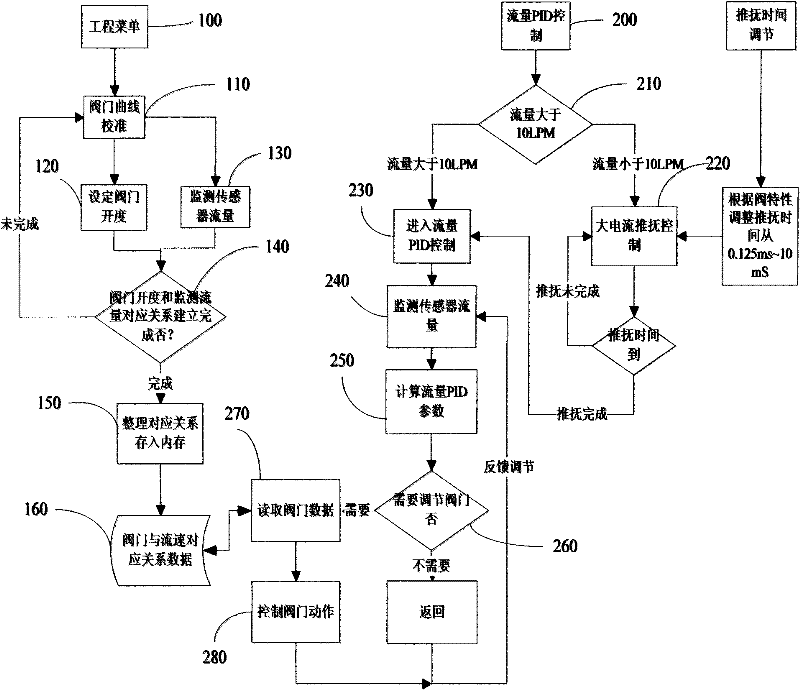

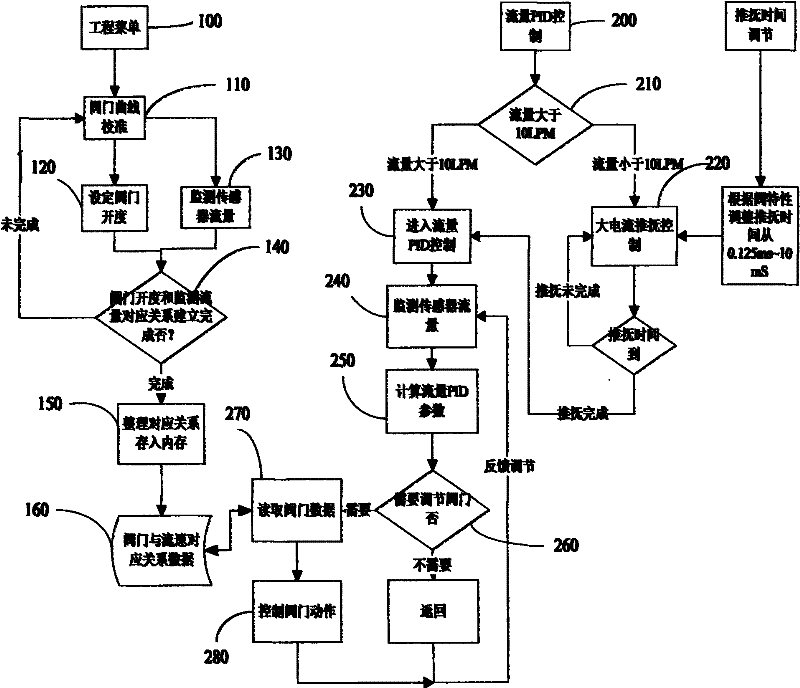

[0027] The basic method of this method is: 1. Store the flow value corresponding to the proportional valve opening control curve into the readable and writable memory in the controller, use the flow sensor and the proportional valve to form a PID control system, and calculate the feedback by adjusting the PID control parameters To control the flow rate, determine the opening size of the proportional valve by querying the flow rate value corresponding to the corresponding proportional valve opening curve in the memory, and monitor the loop feedback through the flow sensor. 2. Set PID control parameters for different required control flow levels, and the parameters of each level transition smoothly through linear fitting. 3. In the small flow control below 10LPM, an adjustable short-time high current impact is added to the initial moment of each flow from 0LPM to the required flow, and the current is connected to the electromagnetic coil in the proportional valve. The spool in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com